Did not sleep well last night. Turning lots of motors and things over in my little sleepy head.

OK. lets start at the beginning of this problem.

1) Like Niel was saying I have run the motor too slow to the extent that the motor stopped before I hit the STOP button.

2) When the motor stopped last week while working it not not going fast as I was cutting a piece of stainless with a hacksaw. Slow speed and working the saw over it.

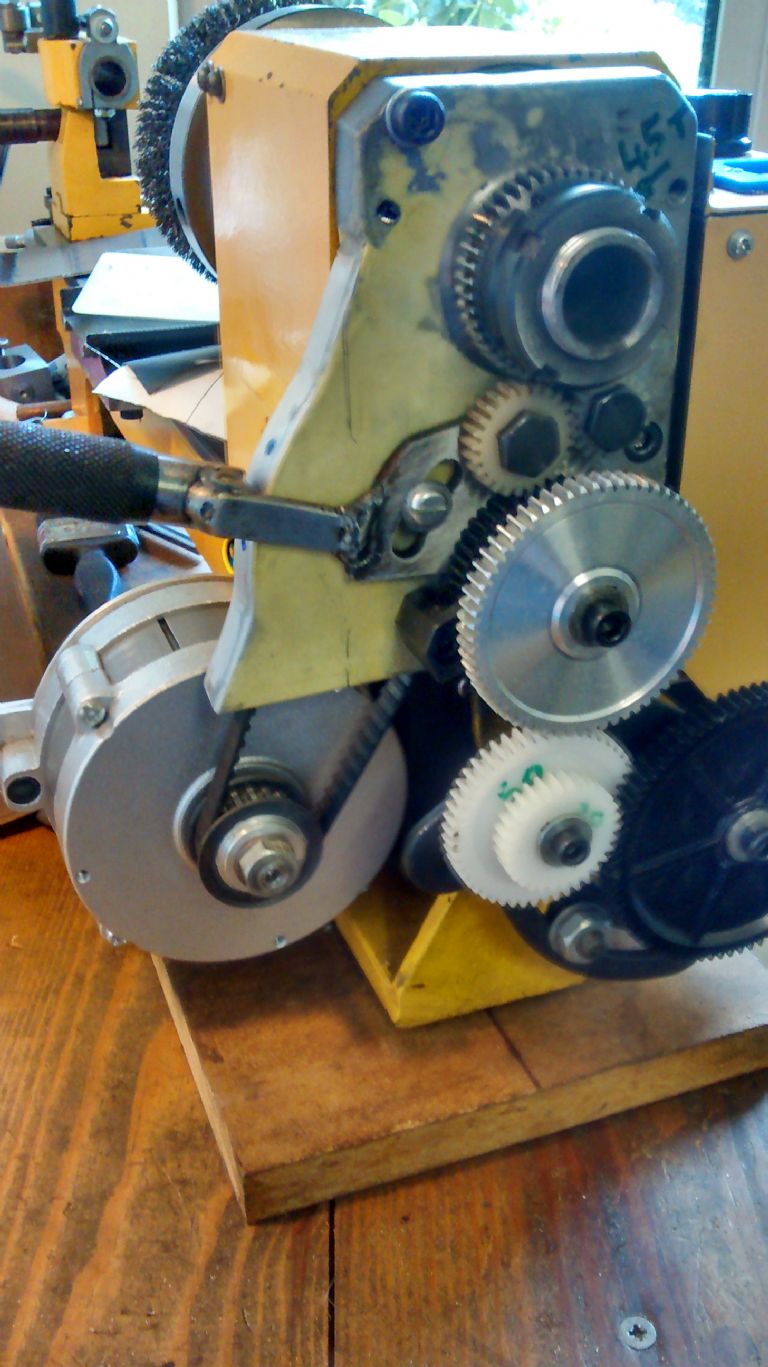

3) Then there was the bang and some smoke and the lathe stopped. It blew the lathe fuse, the light over the lathe, the garage fuse and the house fuse all in one go.

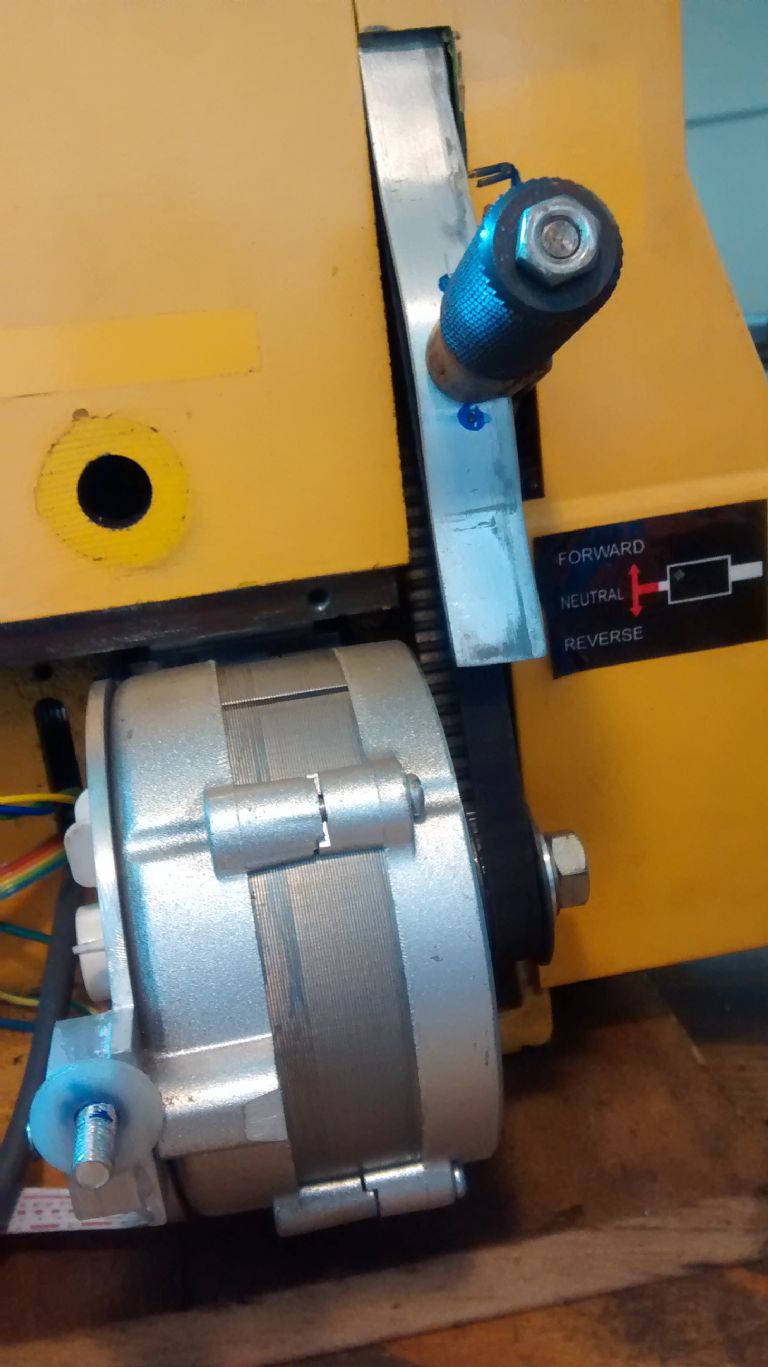

4) I am now thinking that the lathe control circuit board let in the AC 220 and cooked the motor. Just a big thought!!!

If this is the case, I will also need a new control board at another £100 or so.

How would I check the control board before fitting a new motor and maybe blowing the new motor on first switch on!!

Jim O’Connell 1.