DC Injection braking:

Firstly thank you for a positive reply. There are several ways of doing this, and it depends on what motor is fitted and what supply is going to be used.

DC braking is provided by some VSD drives as a built in feature which can be selected as part of the set-up parameters. I've got several Telemecanique Altivar drives which offer this facility. But that assumes you were going to go the VSD route. Otherwise you can buy a safety module which fits into the motor circuit to provide DC braking as a specific function. Essentially all it does is introduce DC current into the motor windings briefly after switch off, which acts like electric treacle and makes it very difficult for the motor to turn.

You can also buy a microswitch which mounts on the spindle head, with a telescopic "radio aerial" poking into the work area. If the microswitch is tripped the supply to the motor is switched off, and the braking effect is automatically applied. If set up right it can bring the spindle to a very smart stop.

To help in suggesting something suitable, could you post details of where you are (first three digits of postcode is ideal) 'cos someone with appropriate experience may be able to help hands on.

Also ideally a picture of the spindle motor rating plate to show kilowatt rating, supply voltage and full load current, also motor windings configuration. If not a picture can you post this information here?

What supply do you have at your workshop location (three phase/single phase?) and voltage, also current rating.

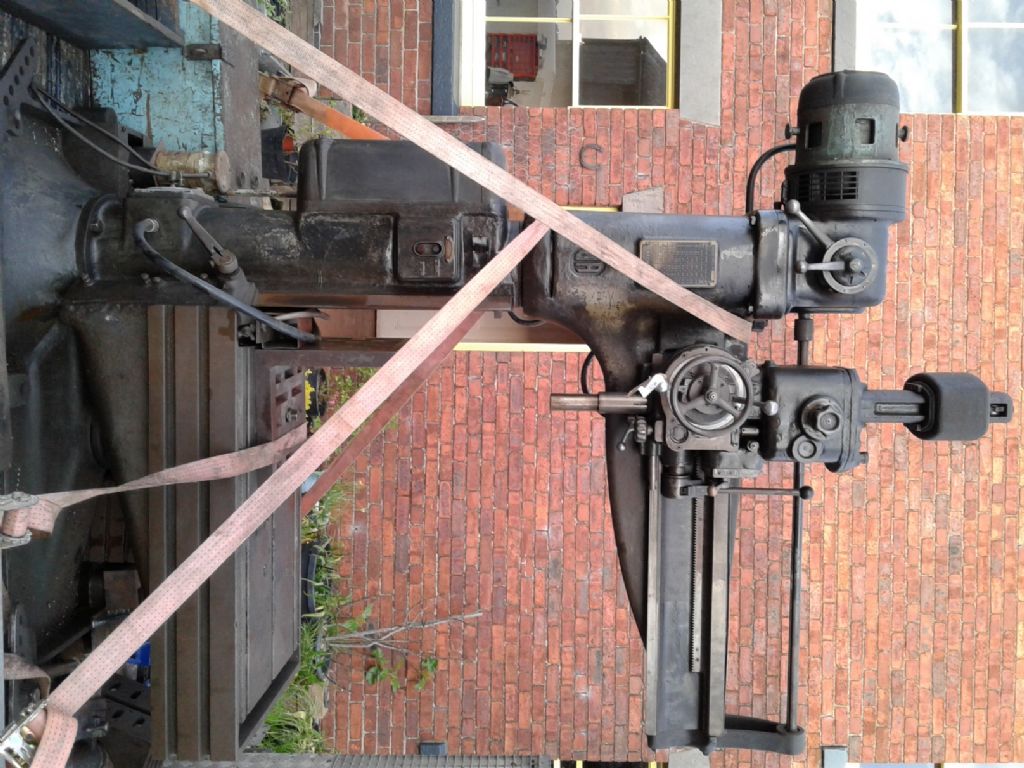

Does the machine have more than one motor – does it have a motor to wind the head up and down the column?

Have you got a control panel supplied with the machine? If so can we have a picture of the front of it.

Looking forward to hearing further, best rgds Simon

Ex contributor.