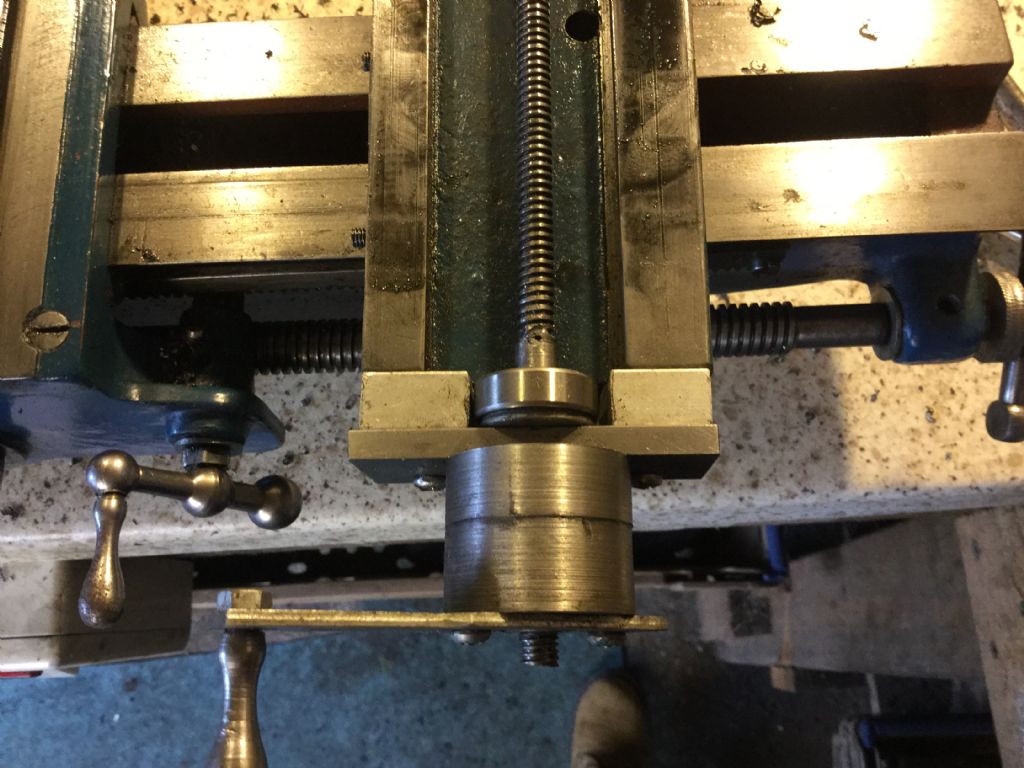

Why not have a go at making one? My lathe has, as standard, a non-T-slot cross-slide. I also have a T-slotted cross-slide which was supplied as a special , but to use it requires transferring the existing handle & leadscrew from one bit of gubbins to the other, something of a pain and which doesn't really encourage me to use the T-slotted device especially as adjustment for smooth handle rotation can be a bit problematic requiring gentle adjustment withing the clearance of the three fixing screws.

My lathe (Warco 220) is metric throughout so I assume the leadscrew is metric. I've ground up a tool from an old file and made a gauge from a piece of 1mm steel, and experimented with it. First time was a disaster as the tool broke, and before I realised, nicely gouged the test thread I was making. Tried again, with complete success, so I'm now about to set about making the complete item.

Dimensioning was easy – measured the OD of the existing, and the pitch, and looked up everything on the internet and other places. Tip width was a problem – eventually I set the micrometer to the required value and did it by comparison of the tip against the gap.

I'm not sure what steel I should be using, but given the amount of use it will get, I suspect good old EN1A will be ok, and that's what I'm using. It runs in a brass nut incidentally.

Regards,

'av-a-go Joe' AKA,

Peter G. Shaw

mark costello 1.

mark costello 1.