Neil,

Both, estimated and accurate formulas are comparably complex if one has access to trig tables or adequate calculator and wish to work in radians.

Extreme cases are used for checking only. I got alarmed because one extreme case where d1=2l and d2=0 would give a result which can be expressed as l = a x pi + b x sqrt(c).

However it is obvious that l = pi x d = 2pi x l.

It is *impossible* to get an accurate pi x d from the sum of a x pi and b x sqrt(c) if b x sqrt(c) is *not* equal 0.

Hence it was immediately obvious for me that you have given an estimate where errors are produced by replacing lenghts of arcs with lenghts of chords or alternatively you have made a mistake. Because I have never done such calculation in the past and I am designing 2 step pulley system meant to work with *the same* belt, I was just wondering what sort of error might be there, just to make sure that fabricated parts (or one of them to be precise) would not go directly to scrap. Indeed, as you say, in normal situation the error is small enough to ignore. Just wanted to make sure.

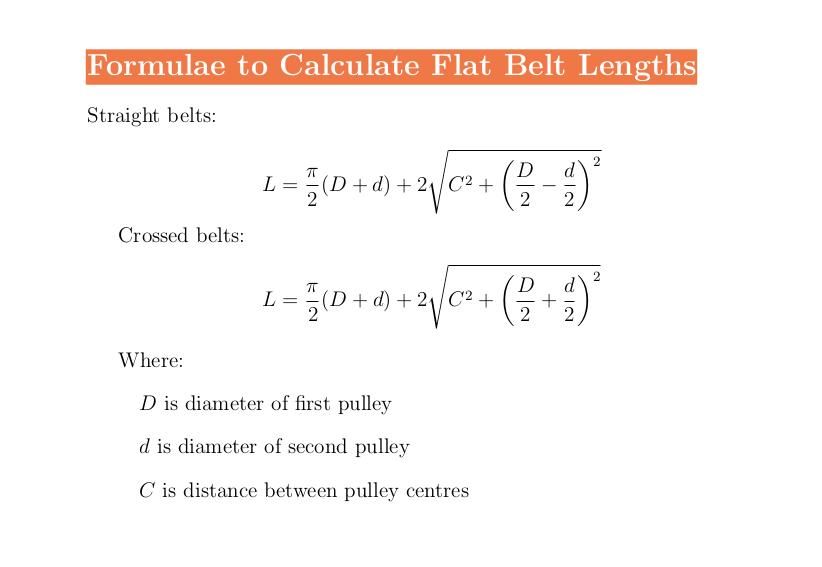

For reference of this forum I will quote an accurate formula from discussed book:

l(belt) = pi/2 x (d1+d2) + *alpha* x (d1-d2) + 2 x l x cos*alpha*

where: sin*alpha* = (d1-d2)/2 x l and angles are expressed in radians, eg 360deg = 2 x pi.

*alpha* is an angle between "squared" situation, eg one where d1=d2 and "triangulized" one, where it is not the case and last point of contact of belt with pulley is shifted by an angle.

You do *not* need to know *alpha* a priori.

l(belt) means lenght of belt, d1 & d2 means diameters of pulleys and l is a distance between centers of rotation of pulleys.

Hope, I have written it clear.

Anyway, we have managed to convert something what looks trivial into quite lenghty discussion. It is interesting that an accurate formula is somehow well "hidden" on Internet.

Martin

Edit:

Hey, lets make it now more complicated, get rid of *alpha*, and put it into one final phrase:

It is known from secondary school that sin^2*alpha* + cos^2*alpha* = 1

so: cos*alpha* = sqrt{1 – [(d1-d2)/2 x l]^2}

so the final, one phrase equation devoid of *alpha* will read:

l(belt) = pi/2 x (d1+d2) + arccos*sqrt{1 – [(d1-d2)/2 x l]^2}* x (d1-d2) + 2 x l x sqrt{1 – [(d1-d2)/2 x l]^2}

where: *sqrt{1 – [(d1-d2)/2 x l]^2}* reads in radians.

Now I will go to do something useful

Martin

Edited By Martin Dowing on 29/10/2017 11:25:16

duncan webster 1.