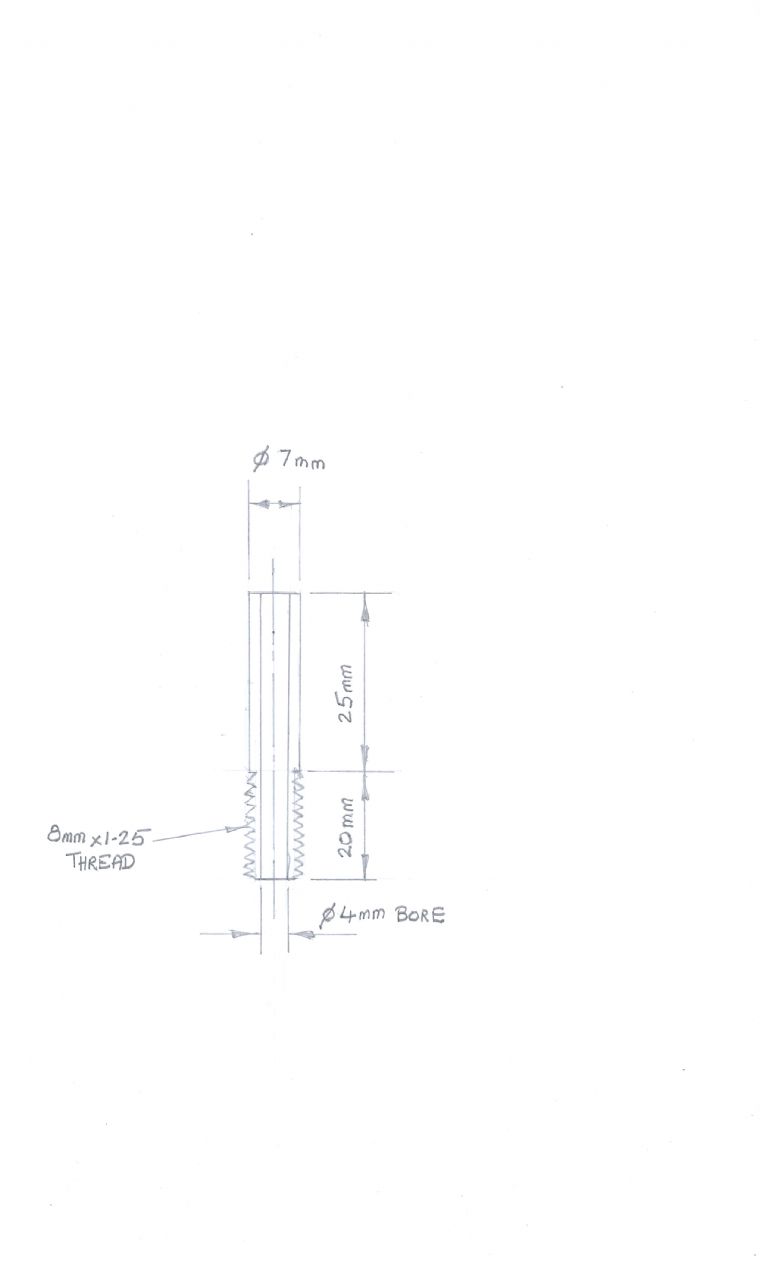

I’ve managed to tap an 8mm hole into the nut on the axle, thinking as already mentioned, get an 8mm screw or bolt and drill a hole down the middle of it and then try and sand the end down to 7mm diameter, the rubber tube I’d be using is fuel line J-30 ¼" bore, I know its rubber and I could put it in hot water to soften it but I’m not sure if it would stretch to 8mm without sanding the bolt down to suit.

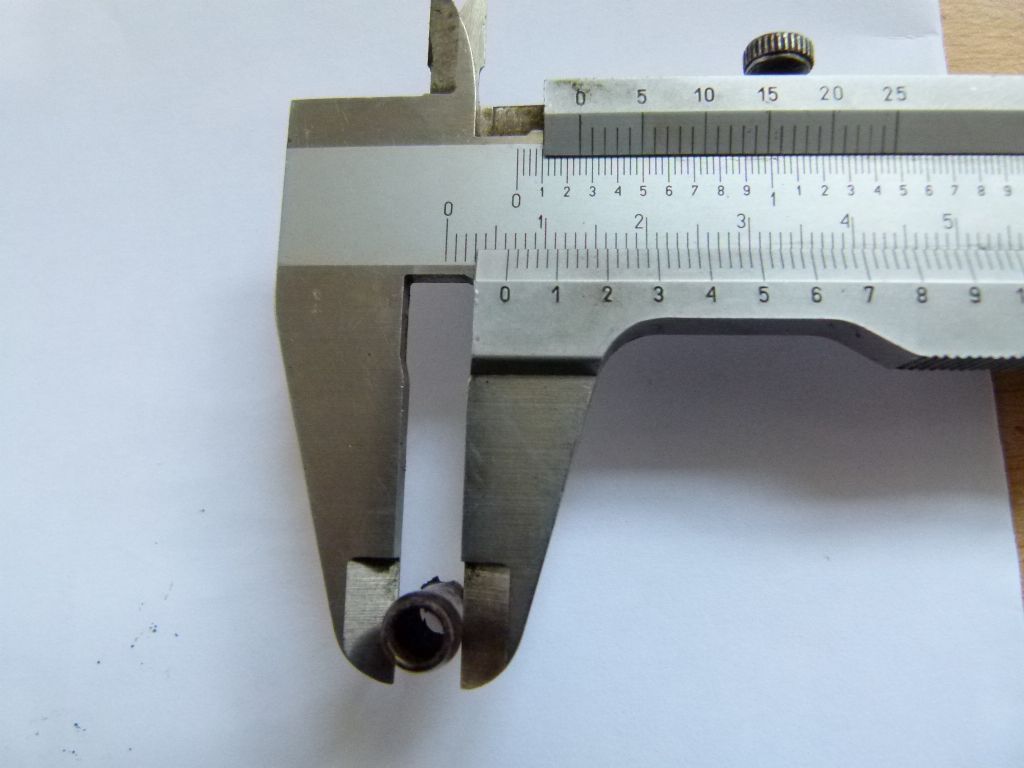

Back to drilling, I don’t have a drill press or pedestal drilling machine and my hands aren’t as steady as they once were but I’ve had a go at trying to drill the bolt with a 4mm drill bit and manage to break 3 bits.

I then decided on this forum thinking with the correct tools someone on here will just laugh at this and more than likely have it done faster than I can put the kettle on for a cuppa 😊

Bill thanks for the link, I want to run it straight up from the axle rather than come out horizontal and then bend it upwards.

Right guys update today 11th Oct:

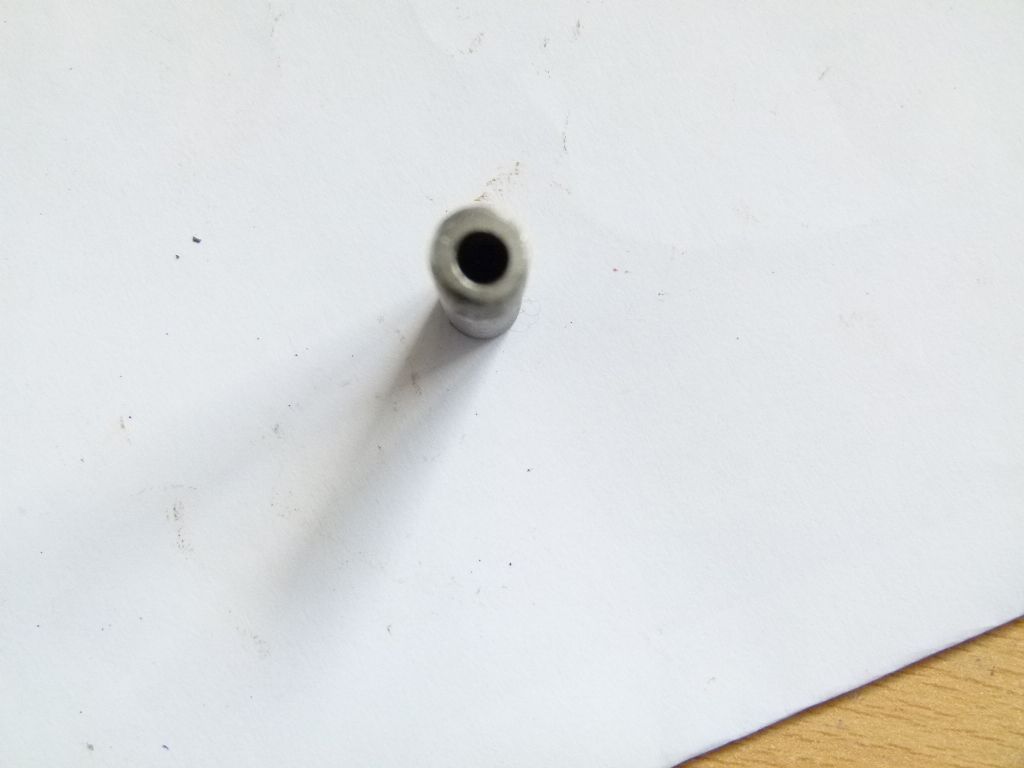

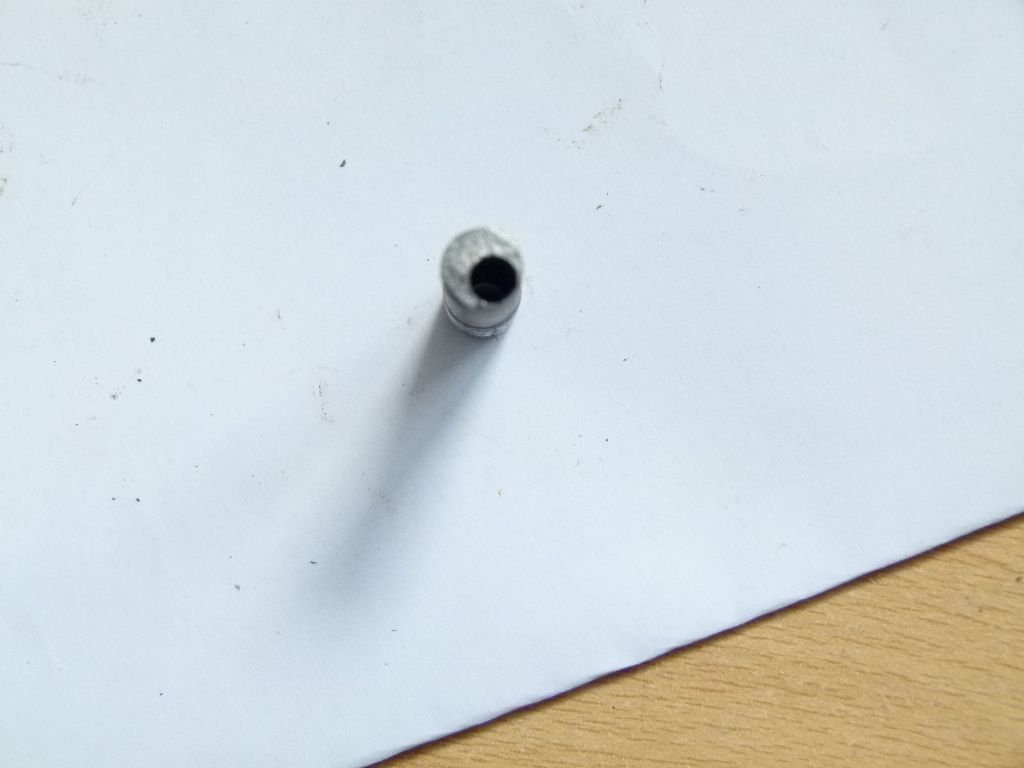

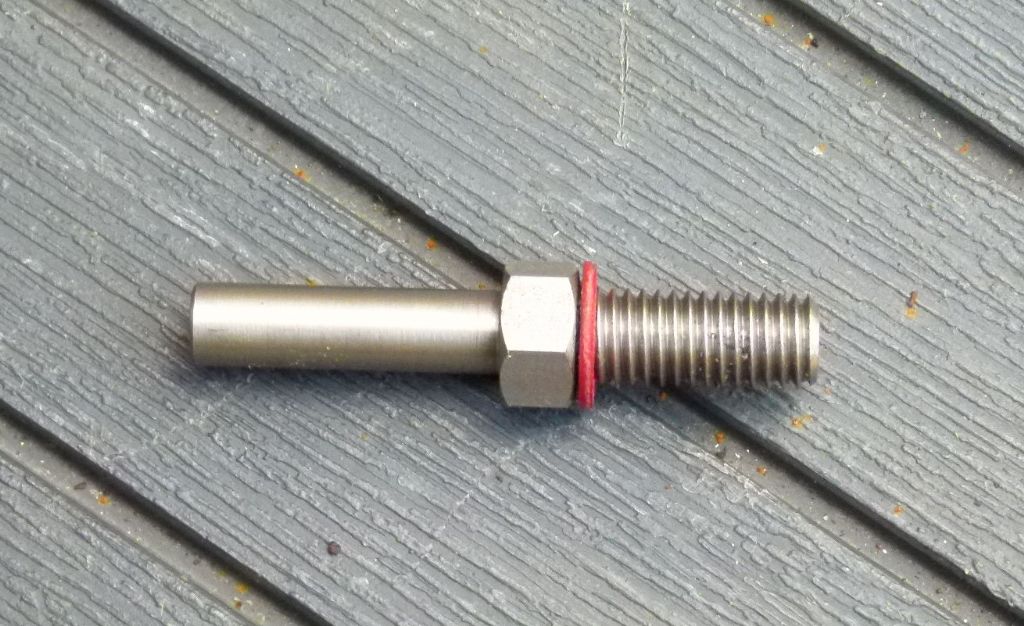

I’ve just had another go at making the steel tube connector, I clamped the head of a bolt in a small vice and put an electric drill in a small drill stand and thought things were looking good until I cut the head of the bolt off only to find the drilled had almost broken through the side see the pictures.

I’m not expecting it to be dead concentric but my effort leaves it hopelessly out.

This picture shows what the rubber breather hose connects to just under the car floor rather than on the axle.

So if someone can help me out I can get on with trying fix the fuel lines,plus two places which I need to get welded at the front of the car, I can do the metalwork but will need to get a mobile welder to weld the plates on, which leaves one other thing; play in the steering wheel, not rotatory but physically getting hold of the steering wheel and moving it up and down it the verical plane.

I know they have 3 different height settings they can be put in, but I guess it must be something to do with the clamping mechaism, other than that I'm having a great day

peak4.

peak4.