Yes I am bonding 2 large 100cm x 100cm sheets of Melamine Faced MDF. I am wanting to create a rigid work surface that is as flat as possible. Most of the time it will be used on a table but under a cutting mats.

In terms of what I already have:

A) PVC wood glues – It sounds like they would shrink but they would take "forever" to cure by evaporation through the Melamine.

B) Original Gorilla Glue – is a water activated polyurethane that expands (a lot) before it sets. If any additional moisture is required to diffuse into the glue (beyond what is already on the surface), that might take a long time too.

C) Collall All-Purpose Glue – is solvent based (acetone+ethanol) I think, so again the solvent would presumably struggle to escape.

D) Sealants & rubber glues (various – e.g. CT1, Dowsil 732, Sikaflex EBT+, Sikaflex 508., Shoe Goo, Shoe Goo2 etc) – but I think they are either cured by moisture going in or solvent coming out. Melamine might interfere with either process.

E) Various Super-Glues – (which I find hard to use reliably)

F) Epoxy Resins (e.g. BSI [Bob Smith Industries] 5 min Quick Cure, Zap Z-Poxy 30 mins, J-B Weld original "Cold-Weld"…)

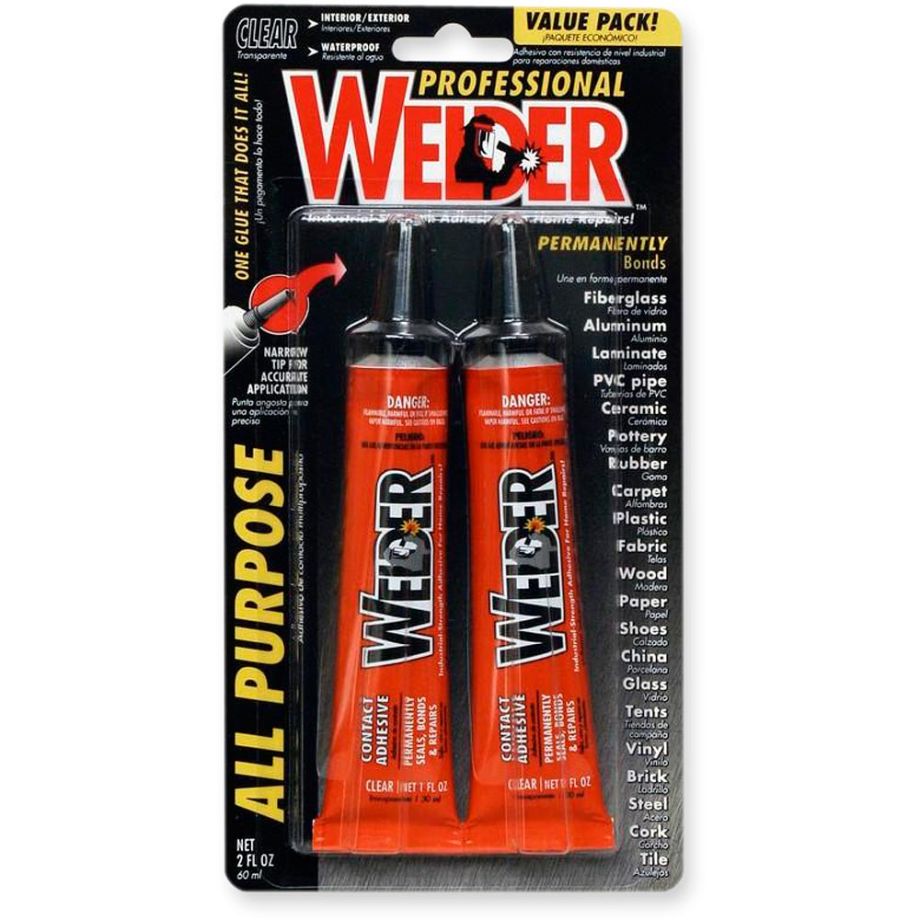

G) Contact Adhesive – I do have some "All-Purpose Professional Welder Adhesive". Would that do?

Titebond Melamine Glue sounds promising – however would need to buy it.

So it sound like a toss-up between with my "All-Purpose Professional Welder Adhesive" or an Epoxy Resin?

Any further recommendations?

J

Robert Butler.