Posted by ega on 02/04/2020 11:02:16:

GHT was somewhat critical of the design but was a boon to many MEs of the day and AT was a real benefactor to the movement.

To be fair I think that "somewhat critical" is perhaps over-strong in relation to what GHT actually wrote. George was, I think, well aware of the real world limitations of money, time, skills and equipment that meant "home shop guy (or gal)" often, of practical necessity, had to accept working with things of less than ideal construction or capacity.

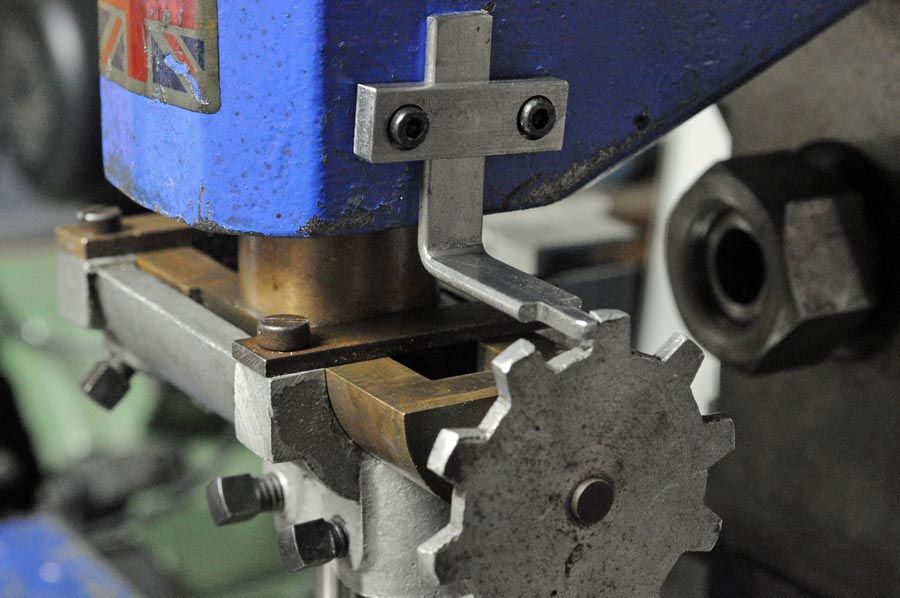

But just as LBSC set out his stall as "Yes You can make a little locomotive", George set out his as "Yes You can make equipment just as good as the professionals do". So in that context pointing out that if you are able and willing to put significant extra work in you end up with a rather nicer piece of kit than just following the standard words and music is reasonable. Nothing that George wrote implies that the standard one isn't functional. He just reckons, justifiably, his version works better and is generally nicer. Although I'm not completely convinced that ditching the star wheel and loosing the ability to automatically face the bottom of a bore is entirely ideal. Even though I've never needed that capability in 40+ years of metal mangling. I'd consider a graduated dial essential tho'.

George said

"apart from disliking the star wheel and striker which linits speed and imposes severe impulse loads there were other features that did not appeal such as the locking screw impinging on the sof gunmetal casting, the tops of the threads of a piece of screwed rod running in holes in the gunmetal casting, the screw should have been left handed, there were no means of determining the amount of feed, there was no adjustment for the sliding member, finally I didn't care for the method of holding the boring bars in the alloy casting.

These look to be quite a catalogue of complaints but they are all matters of detail that can be modified to suite the particular whims of the maker. These details attended to the result is, as far as I (GHT) am concerned, a serviceable head for larger work of a lighter nature. For the beginner who is not able to undertake cutting the dovetails on the small boring head (GHT design) this is a useful alternative that is much easier to make. The other (GHT) head is more sensitive and can be run much faster."

The GHT head is also of smaller capacity.

Seems to be a precursor of the "far more than can be conveniently counted" words written in recent years on improving the performance of affordable (but somewhat lacking in finesse, precision or both) FE imports.

As ever its about striking a balance. Generally a manufacturer is constrained to accept some imperfection to meet a price that the target customer can afford.

Clive

Edited By Clive Foster on 10/04/2020 14:26:48

Roderick Jenkins.

Roderick Jenkins.