Hi Paul

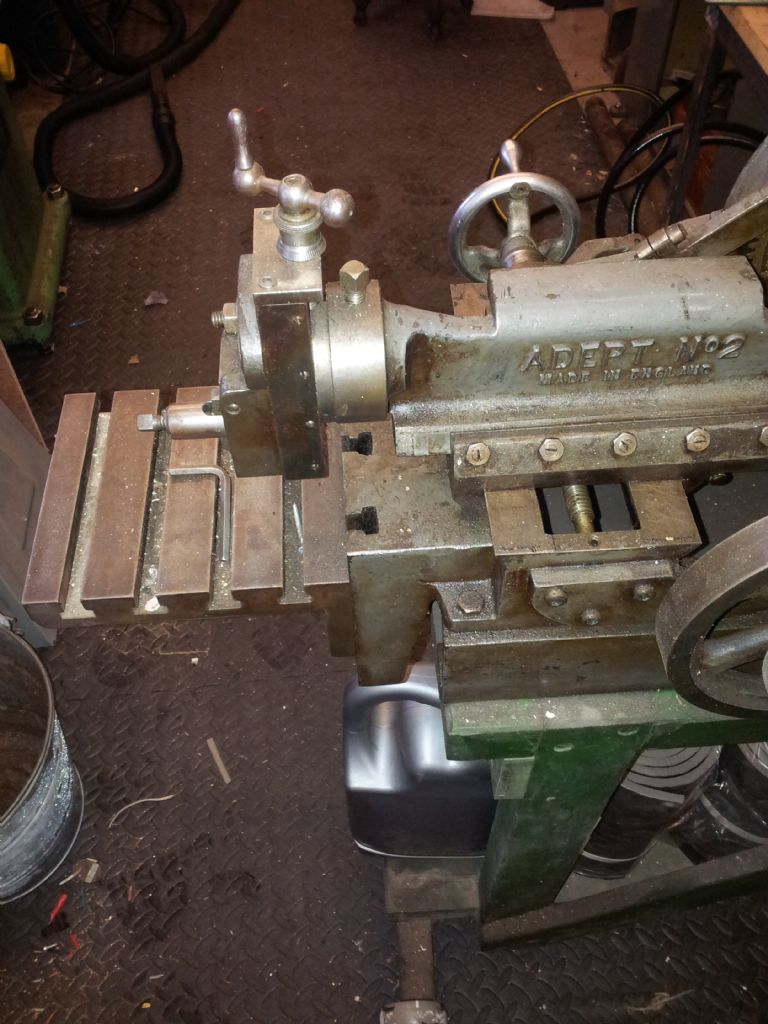

Yes, adjusting the traverse slide gib on the powered model is a most frustrating and fiddly process, which might explain why the several I have seen all needed attention. Access on the original hand operated model is much easier, the motorised version just has all these extra bits added on, which naturally results in something of a compromise.

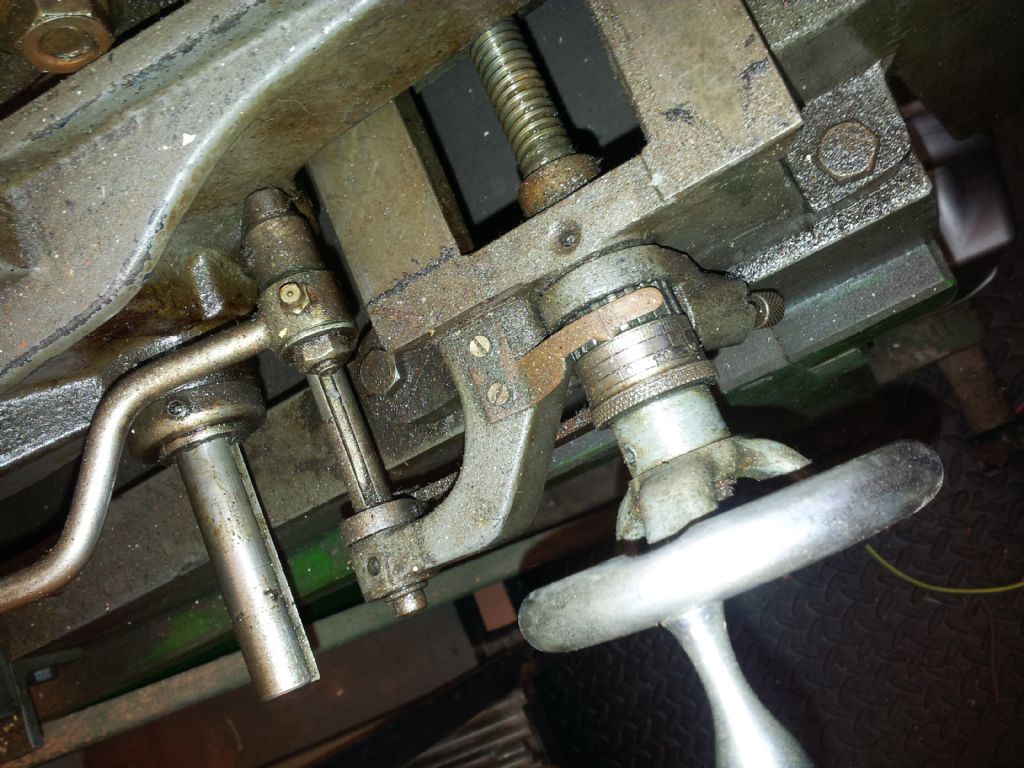

It will probably be easier to at least partly dismantle the drive gear at the rear which will improve access, also the traverse feed screw, so that the body can be moved by hand as adjustments are made. Mine was stripped down so I replaced the much-mangled and too short grubscrews with longer socket head grubscrews, and allocated a shortened ring spanner and allen key to the machine. Subsequent adjustments were quite easy. The ram gib also received new socket grubscrews.

Your machine has a few interesting modifications – the downfeed handle I personally think is an improvement on the original wheel, and it looks as if there is a graduated collar? If not, I can recommend this as a most useful addition. I made a new larger wheel with a graduated collar for mine, which was transferred to a friend’s machine when mine was sold. The traverse mechanism drive arm looks to be a substantial replacement, I wonder what happened to the original.

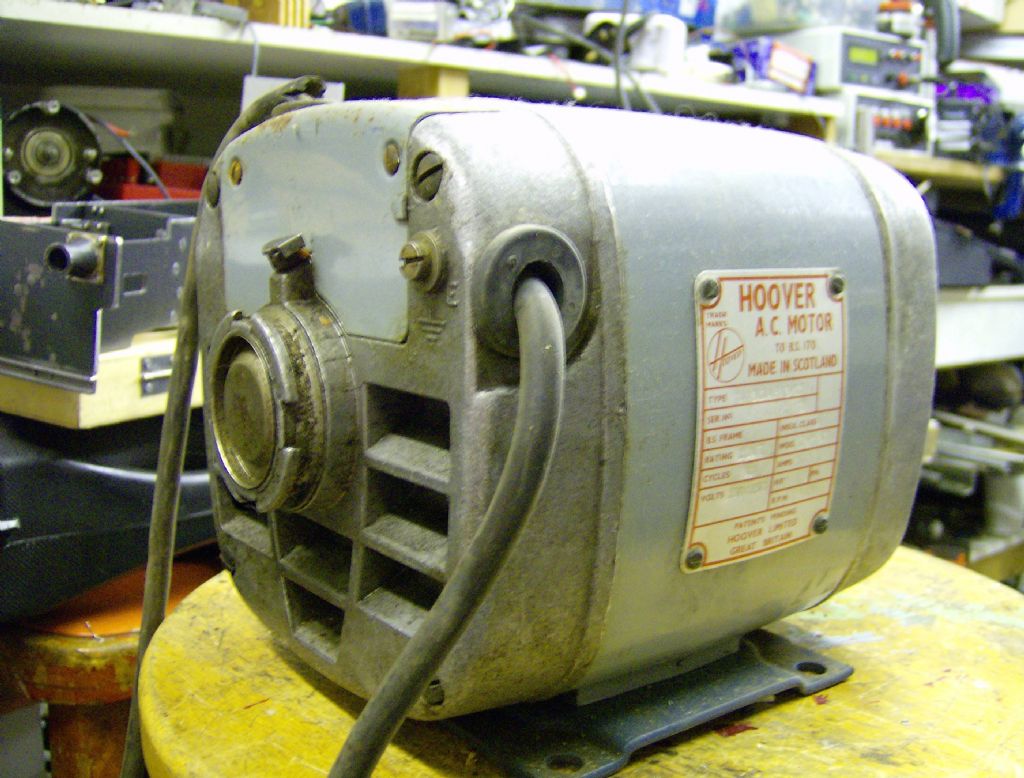

The replacement traverse wheel is big enough to get a proper grip with oily fingers for hand feed, and the auto feed ratchet drum looks to have a friction spring added – when worn the ratchet mechanism can be hit and miss, which can alter the surface finish by varying the traverse feed rate. Mine was friction loaded with a rubber band cut from an inner tube…

Two other alterations worth considering are a dowel to hold the vertical feed gib in place, and either a lock screw with short lever, or one longer gib screw, which can be tightened to hold the down feed slide in position, as it can “creep” during use, which does not improve finish, work piece, tool or temper.

Dave

John Olsen.