Finally the Britan is paying its way. As part of a set of plastic production jigs I am making for a client I needed 33 spacers, each 80.65 ±0.05mm long, with a 5.8mm hole in each end for a threaded metal insert.

It's long been a PITA facing items to an accurate length on my conventional lathe; face off, take the part out, measure it, put it back, take a bit more off and so on. Things are not helped by having a Burnerd multisize collet chuck, which is not dead length, on my conventional lathe. Due to the design of the jig it is important that the spacers are consistent on length as it controls how the internal parts clamp together. Here are the finished spacers:

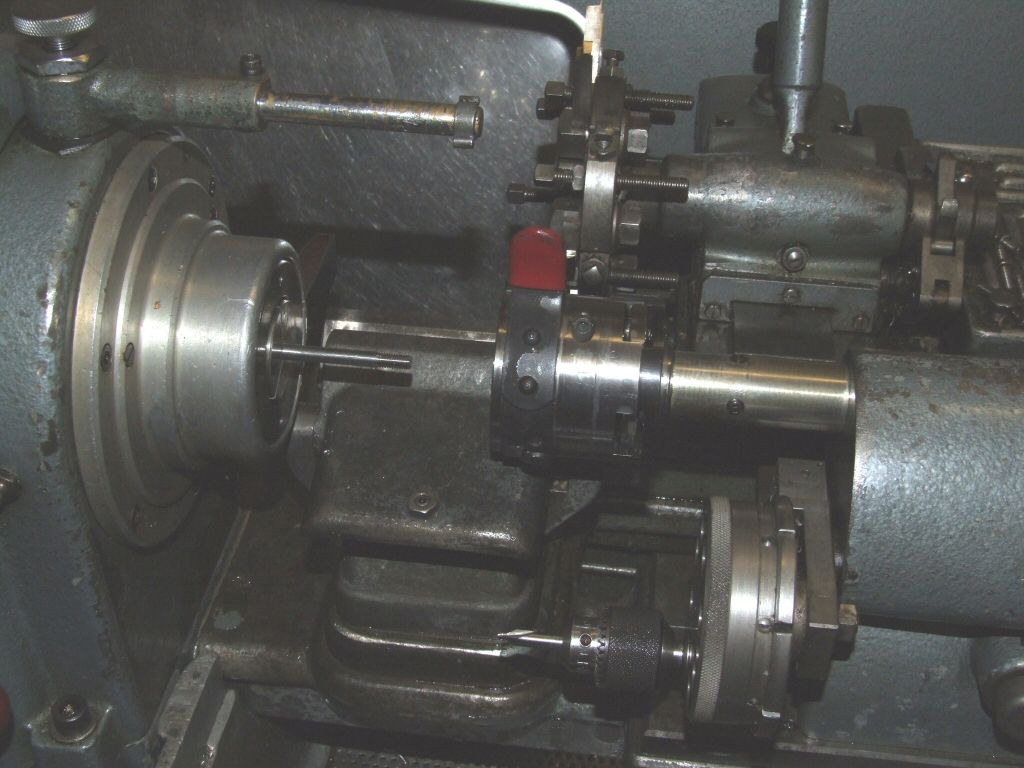

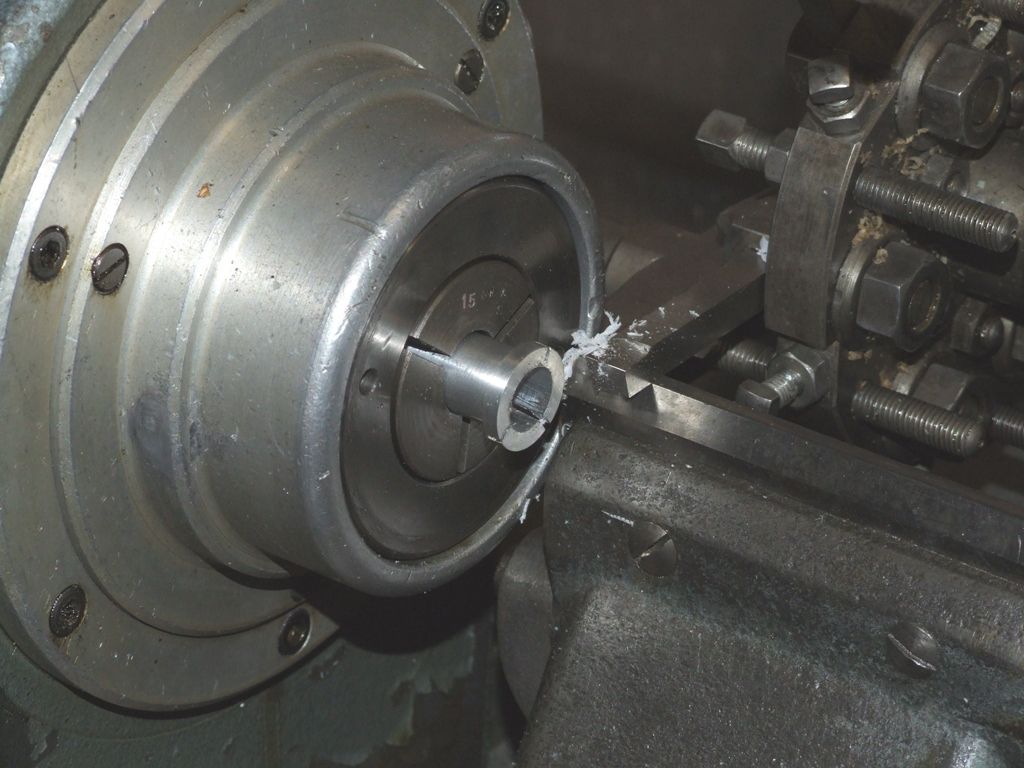

The plastic (delrin) is nominally 12mm diameter, in practise it is 12.4mm. I don't have a collet for the Britan of that size, so I made an aluminium split collet to fit a 15mm Britan collet:

One end of each spacer was cleaned up on my conventional lathe. I then fitted the backstop to the Britan and using the adjustment screw crept up on the correct length for the spacer. Once set up it only took about 15 seconds per spacer to face off to the correct length:

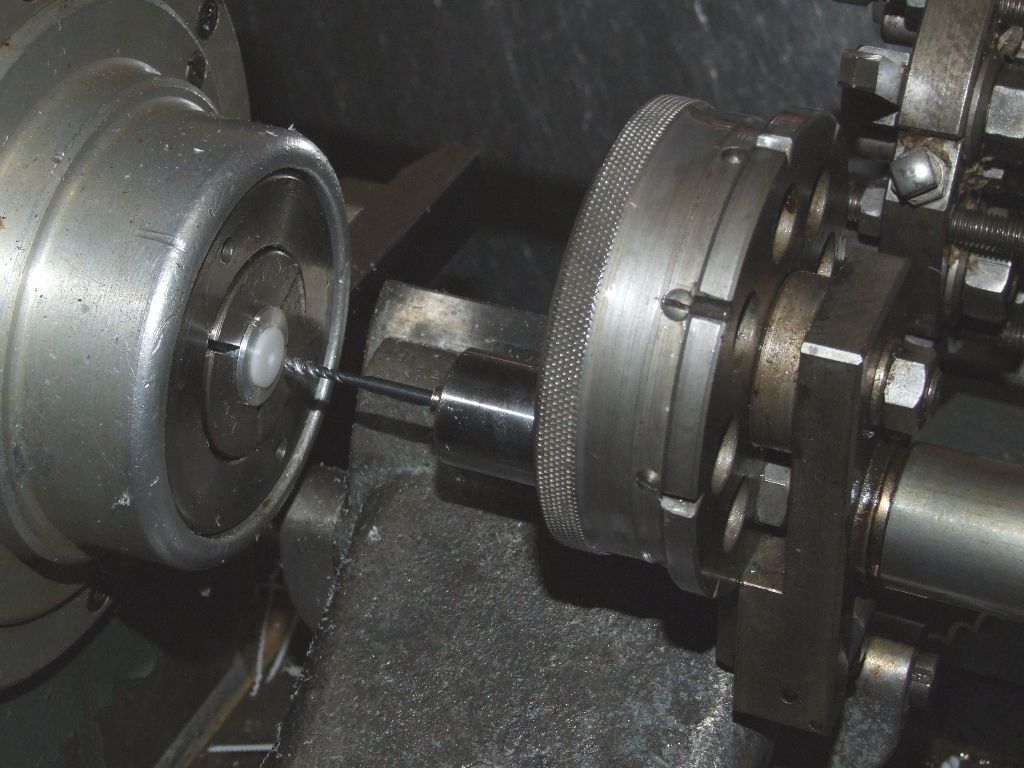

I then used a centre drill (left hand) to centre each end:

And a 5.8mm drill, also lefthand, to drill the holes:

The centre and drill were separate operations, as I haven't worked out yet how to cope with the very different lengths of the centre drill and jobbers drill when they are mounted together. I'm really pleased with the operation of the Britan, it made what is normally a tedious and long winded job very simple. Doesn't happen often, but definitely one of my better buys.

I quoted a fixed price to make the jigs, so I'm feeling rather smug that these parts took a lot less time than I budgeted. Tomorrow I'll make up a simple adaptor to fit the threaded inserts, while ensuring that they go in square.

Regards,

Andrew

Anonymous.