Posted by duncan webster on 12/02/2022 15:50:10:

SOD tried to argue that putting a worktop under a lathe would make the load applied from the floor to the concrete uniform. The lathe is (I assume) applying 4 point loads, so that would be exactly equivalent to having it upside down on 4 points supporting a uniform load as I said. It is irrelevant that you could support 800kg on a worktop by supporting it properly, you could put more legs on the lathe if you were that way inclined.

In reality the board will spread out the load a bit but to nothing like that extent. To work it out properly would not be trivial. According to Google the Young's modulus of 'particle board' is around 0.3 GPa Echip, whereas concrete is between 30 and 50 GPa Econc depending on the mix, say 40, so 133 times greater. Steel is 207 GPa for comparison. Worktop is typically 40mm thick, whereas the OP's concrete was 50mm. Stiffness is proportional to the cube of thickness, so the concrete will be (50/40)^3 * 133 = 260 times stiffer than the worktop. The bending load will be shared in proportion to the stiffness.

In short, the concrete needs to be thicker, even my kitchen floor is 100mm on top of 100mm hardcore, and the heaviest thing on that is the washing machine. Actually it's me, but we needn't get personal!

Not guilty this time, because I don't claim the load under the worktop is uniform!

All I'm saying is putting a worktop on the floor under a lathe will spread the load, and if the worktop was perfectly rigid, my simple calculation would be about right. Duncan says, correctly, that the actual pressure depends on how stiff the worktop is.

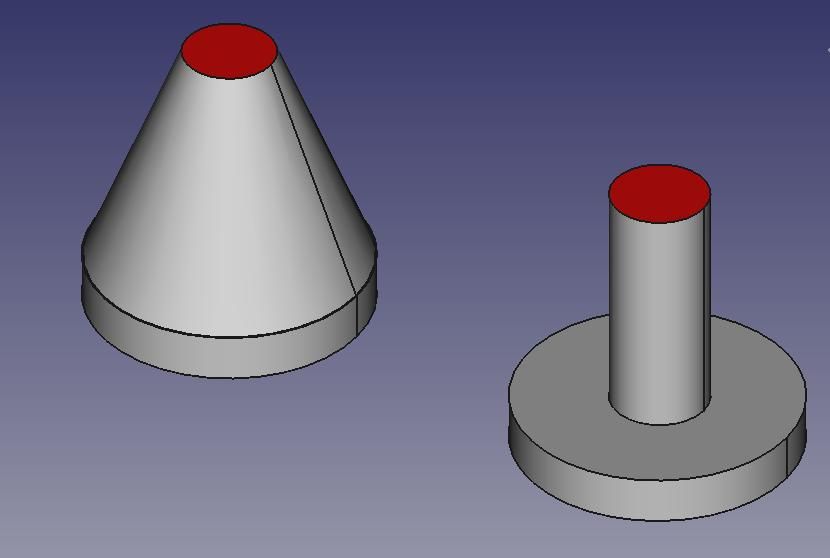

It's the difference between these two constructions:

They have the same areas top and bottom, so a load on the red top would put much the same pressure on the lower disc. The cone on the left represents my view, the column on a disk is closer to Duncan's position. The problem with the column bearing on the disc is that it will tend bend the disc so the pressure underneath isn't uniform: it will be higher directly under the column than at the edge.

The risk is putting a worktop flat on on a underheated floor wouldn't spread the weight of a heavy four-footed lathe evenly enough to prevent damage. An experiment is called for! I can't think of an easy way of measuring or calculating a pressure distribution caused by the support flexing. Suggestions anyone?

On the plus side, heavy objects like lathes are often successfully moved across soft ground by laying boards underneath. On the down side, boarding a lathe safely across a lawn doesn't prove an expensive floor would be completely protected.

Dave

gerry madden.