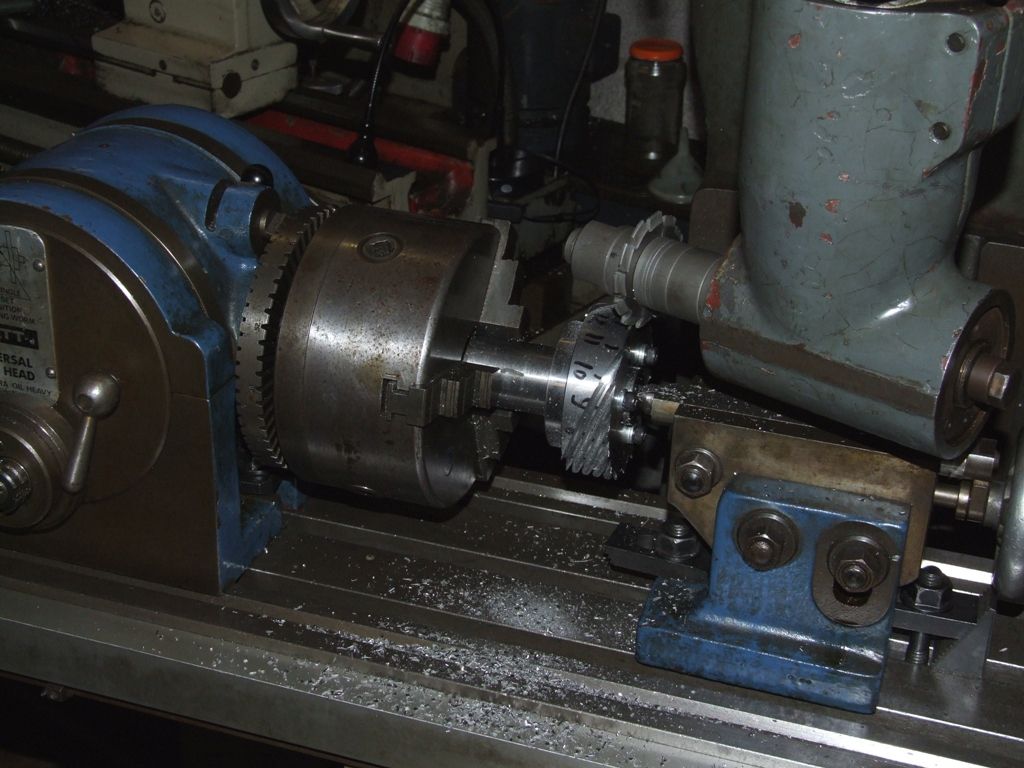

I don't see any reason why you couldn't make a lathe with a lathe, other than size. They are versatile machine tools.

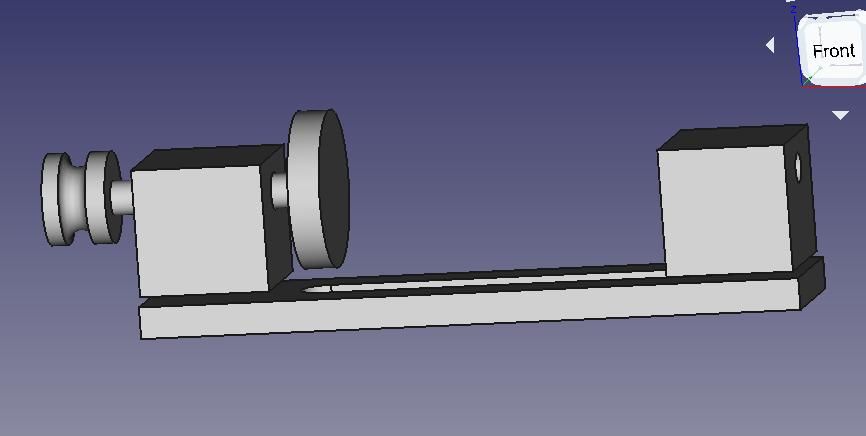

In this CAD lash up the spindle, faceplate, and pulley are basic lathe jobs as is boring the headstock and tail-stock, and making any threads needed. (Didn't bother with a tool-post because it too could be very simple.)

The headstock, tailstock and bed are facing jobs, not difficult on a lathe provided the blocks of metal physically fit. Hardest is the slot in the bed, again only difficult because plenty of room across the saddle is needed. Not insoluble.

All this could be done on an ordinary general purpose lathe like wot I have. But we're not restricted to that. Why not make a couple of large lathe set-ups just to make big lathe parts? Dumping all conveniences would keep the lathes very simple. Might feature a wooden frame with large diameter faceplate, no precision bed, a fixed tailstock, and require careful setting-up. A second simple lathe could specialise in boring, and a third might make round parts only.

In the real world it's cheaper to make lathes using several manufacturing techniques: casting, grinding, drilling, milling & turning etc. But good lathes could be produced by going back to basics. The only component I'm not sure of making on a simple lathe is the lead-screw. Unless someone knows otherwise, that has to be made by hand in the first instance and then, by measuring and compensating for errors, used to make more refined versions until an acceptable level of accuracy is reached.

Dave

PS Aren't lathes the Queen of machine tools? Surely lathes are feminine.

SillyOldDuffer.