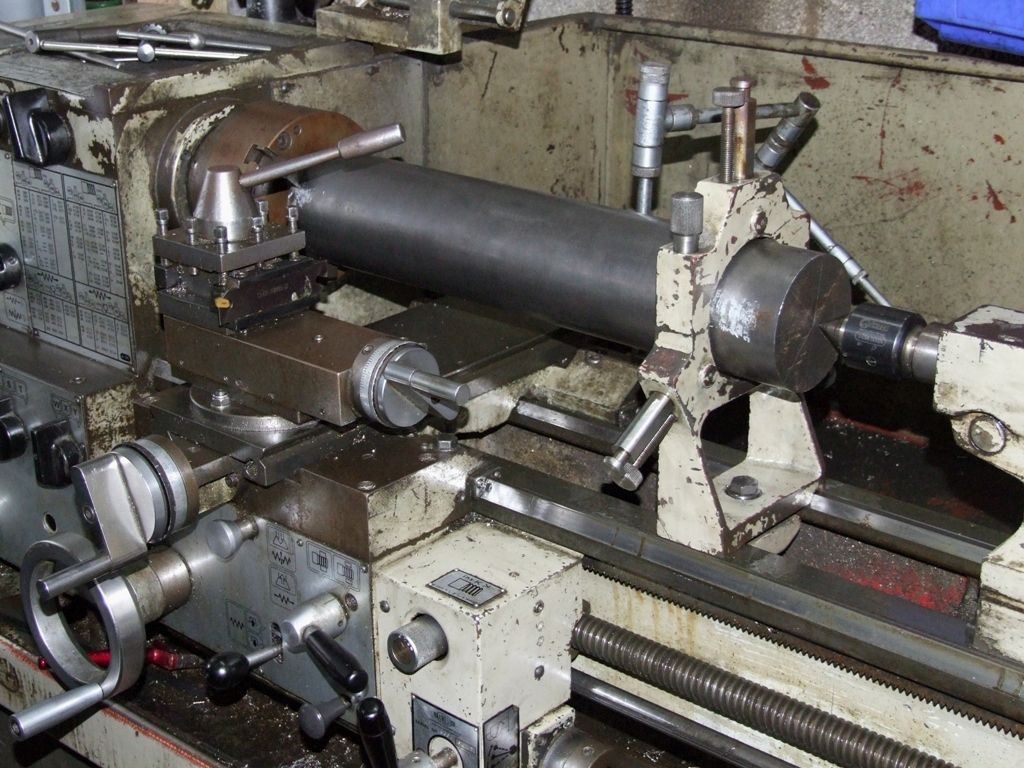

Over the last couple of days I've been machining the taper on the chimney former for my traction engines. Roughing was done at 180rpm, 50 thou DOC and 8 thou/rev, so quite modest for me. The chips were coming off dark blue though. FInish cuts were at 370rpm and 4 thou per rev, DOC as required, but generally 5 to 10 thou. Here's the setup for a finishing cut, about 15 minutes per pass:

The template was marked out and filed, don't need super precision! Note the chimney fixing ring from the traction engine hanging on the tailstock quill to test fit and size. Although it's only a former I couldn't resist trying it in situ:

I've been in discussion with a forum member, via PM, regarding the purchase of such a relatively large lump of steel. I mentioned that I got a rather odd finish, and promised to post a picture. So here it is:

The material purports to be EN1A. The general finish is so-so. It measures 3.3µm Ra, which is ok but not brilliant. Of course that doesn't matter for my application. The really odd thing is the darker bands every ¼" or so. I can't think of anything on the lathe that is repeating at that distance. Although the template is hand crafted I doubt my filing would produce such a regular pattern. That leaves the material. Each dark band is a bit shiny, which I associate with harder material when turning with inserts. I wonder if this is something to do with the extrusion or drawing process? As an aside, when roughing I had some problems with chatter. The chatter distance was short. an 1/8" or less, and at random places. One time next to the tailstock, next time in the middle. And the tool never chattered in the same place twice. Once I'd done a few roughing pases the chatter never re-appeared.

The former has tarnished overnight in the engine assembly area, sorry entrance hall, which seems to indicate EN1A.

Andrew

Nigel Graham 2.