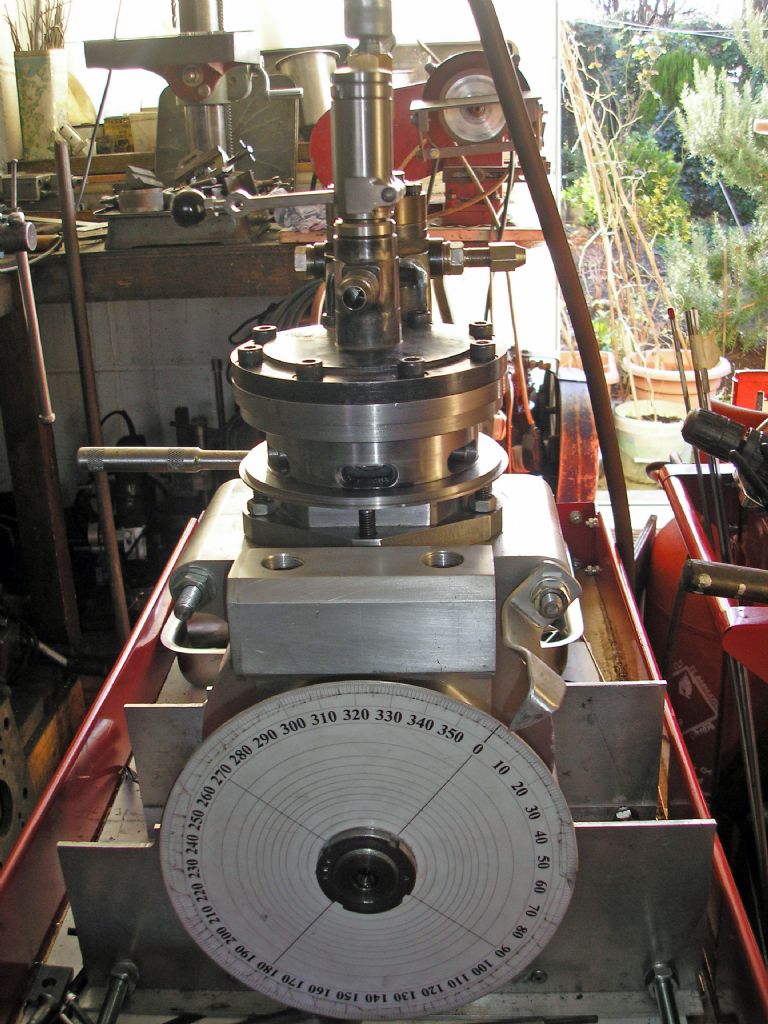

I resumed fitting the 3-axis DRO to the Myford VMC MIll.

I have had the long- and cross- travels working for some time now, and assembled the vertical one this afternoon.

The magnetic strip and its holder are on a length of 2x2x0.25" aluminium angle held top and bottom by M8 studs and nuts screwed into the machine column. After a frustrating half-hour or so trying to align it by DTI, I twigged why it was so difficult (two fulcra in slots a long way apart, on a column not made to hold these devices), and used my best square instead to set it right to the table. That did the trick, according to a subsequent dial test, giving a run-out nicely <0.01" over the 8" or so of travel: I didn't push my luck by trying for the last few thou. That would entail making and fitting proper screw-adjusters.

Setting the gaps between the encoder and strip was simple: I gently held the encoder while tightening the screws, against a plastic "feeler-gauge" of appropriate thickness – a strip cut from an expired caving-association membership card. It's surprising how one hobby can help another despite no obvious connection!

I've still to sort out the cable supports / strain-relief, and fit the swarf-guard to the strip holder, but it's all basically finishing touches now.

It's been a lengthy task, involving a lot of complicated bracket-making and losing the table's long-travel limit stops.

Incidentally, I keep the console clean simply by keeping the Cellophane bag from its original packaging, loosely over it. Not tightly because although the electronics do not generate much heat I still want them able to lose that. I've long kept the workshop calculator in a polythene bag for the same reason.

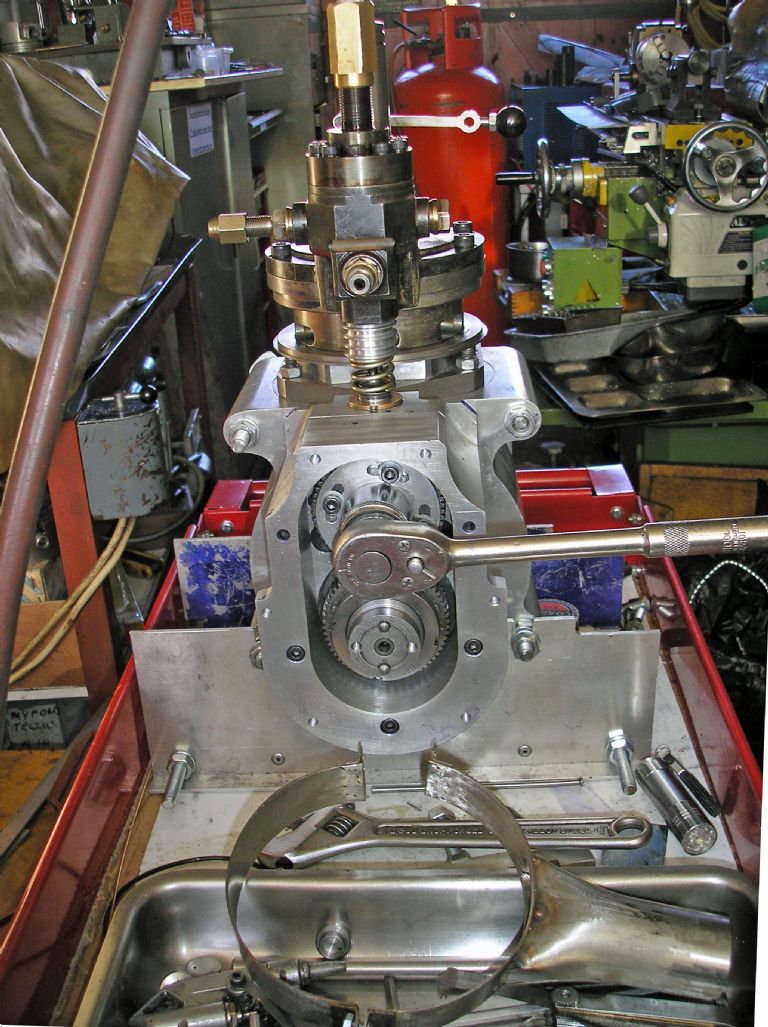

Next up for the milling-machine is its 3ph conversion. I have the motor etc., just need to get on with it! I don't yet know if it will entail altering or replacing the motor plate.

That and sorting out why the quill rise and fall is so stiff it offers no sensitivity for drilling, and won't spring back up. My suspicion is congealed grease, but the innards are hard to reach and I am very, very wary of quill springs.

At some point between buying the machine and transporting it home in pieces, then moving house without yet erecting the mill, I lost the draw-bar for its R8 spindle. However, silver linings and things: I discovered I could make a self-ejecting version, and that extra work has certainly paid off. A lot better than clouting the top of a plain draw-bar to loosen a stuck MT3 fitting, as on my previous mill/drill.

++++

My friend appreciated the humorous "cake square" I'd made for her as a Christmas present – she has an endearing quirk of cutting any slice of cake into neat little cubes.

===

The DRO task made a change from trying to sort out the travelling-hoist runways, and is a project I should have finished a long time ago.

Steviegtr.

Steviegtr.