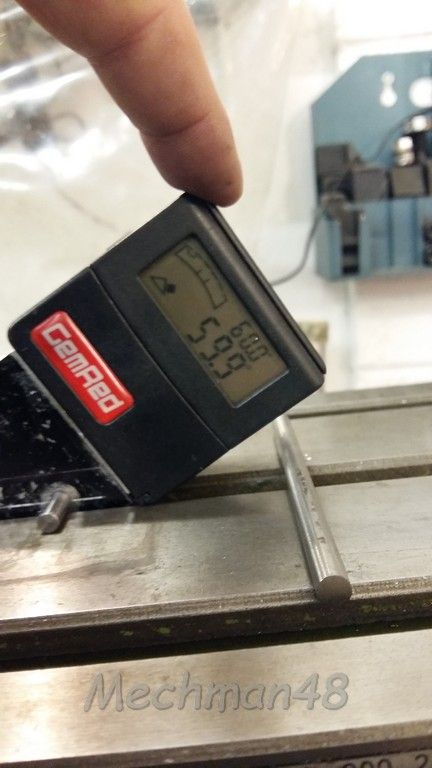

Completed my Drill Alignment microscope jig to align drills in my 4 facet grinding jig ( previously posted on).

The optical head is a Bausch and Lomb Zoom microscope, and I fitted a horizontal reticule in the right eyepiece after some advise and guidance from Robert Atkinson – Thanks Robert!

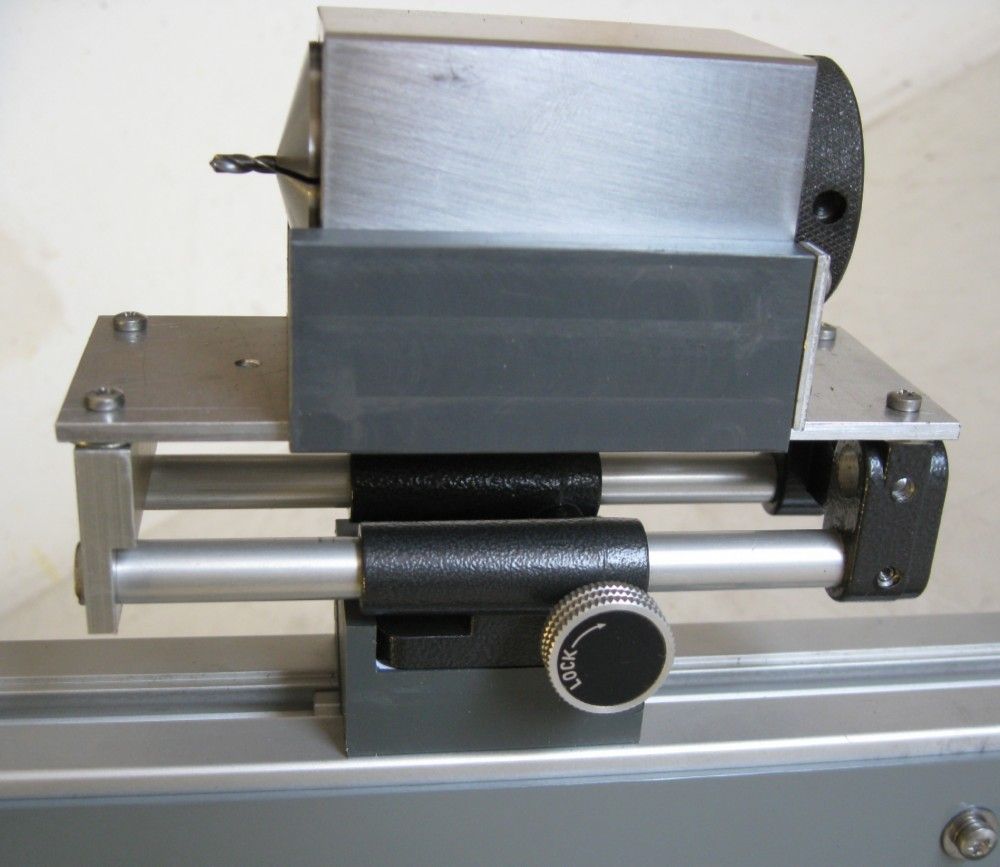

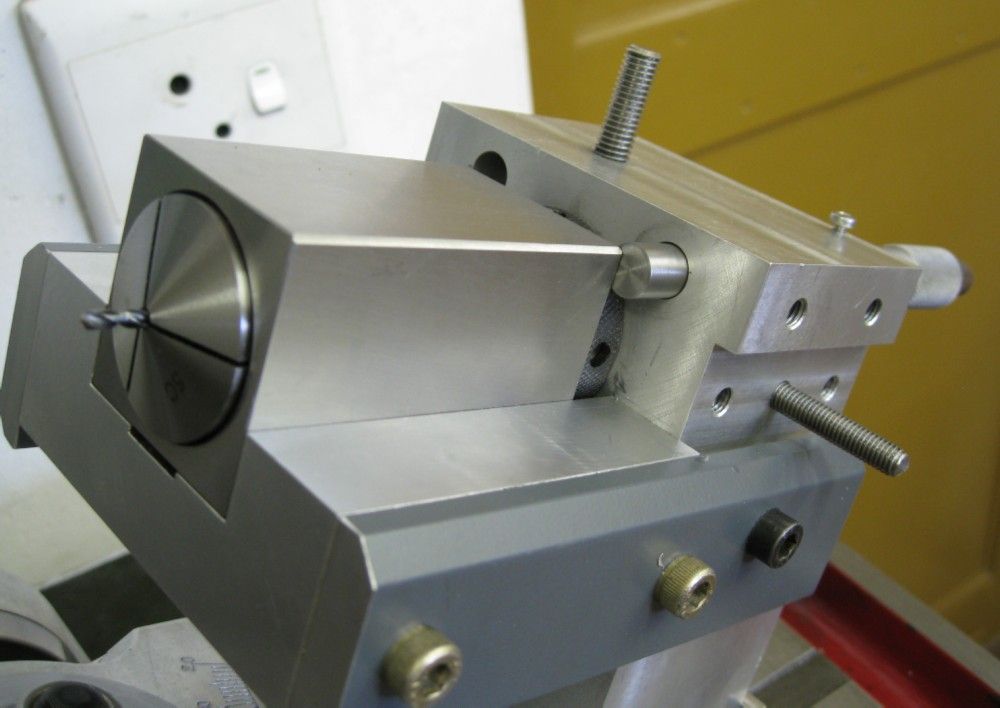

The 5C collet in a square block holder sits on a focusing stage as seen.

The focusing stage – drill end view

Focusing stage – side view

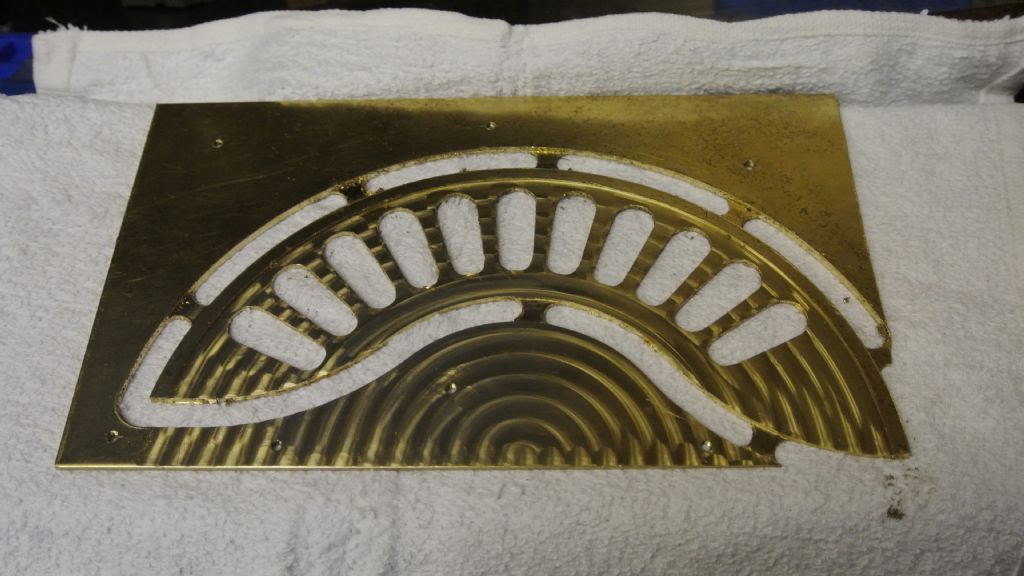

Th reticule is a plastic ring sized to fit inside a threaded reticule holder that screws into the underside of the eye piece. A single fibre of fibreglass was teased from some weave, and superglued to the 180deg apart slots made in the sides of the plastic ring. The ring then inserted in the holder and screwed into the eye piece until focused.

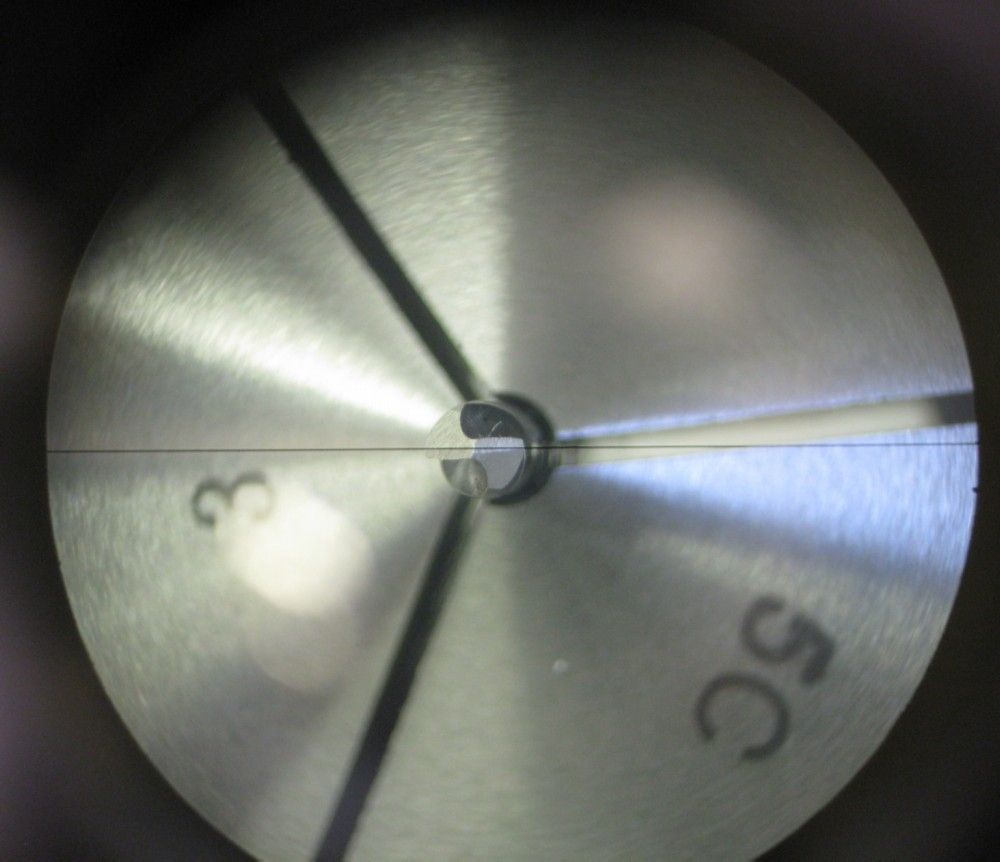

View ( focus was difficult..) of the fibre reticule in place, from the bottom of the eye piece.

View through the microscope, focused on a 3mm drill, showing the reticule.

The camera was difficult to focus, being handheld, so the drill image is not that clear – it is VERY sharp when eye viewed.

The difficult part in the construction was getting the microscope sight-line horizontal and in line with the drill point at all focus ranges and zoom settings.

This at lowest zoom setting – at full zoom the 3mm drill fills just over half the image

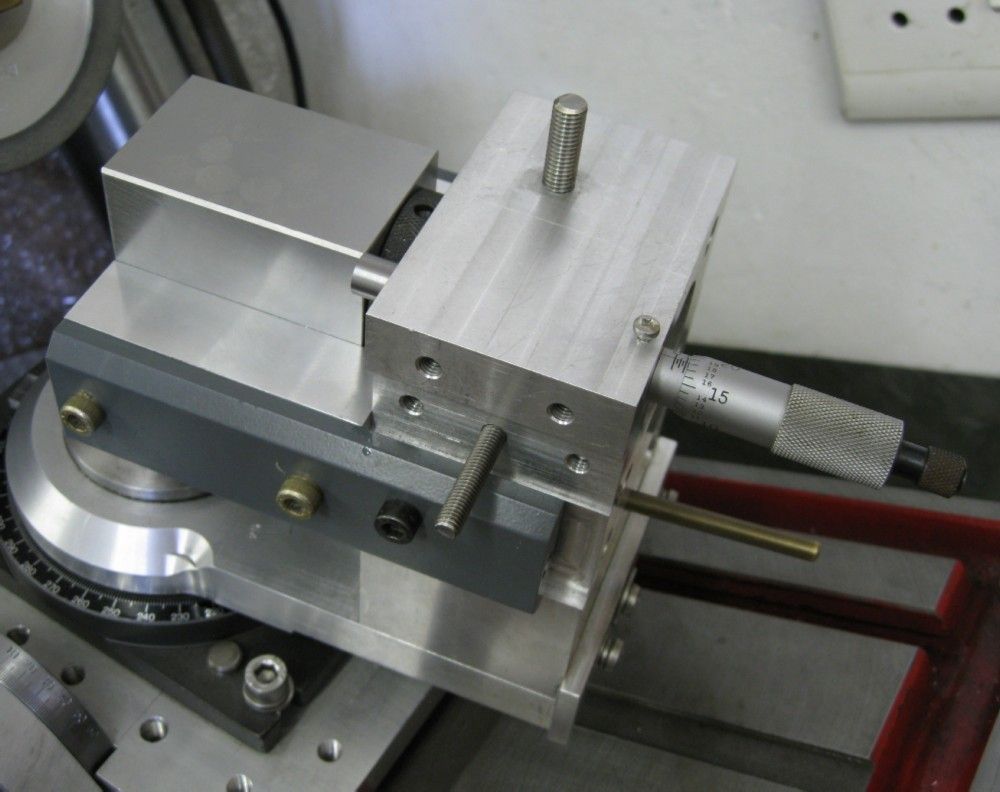

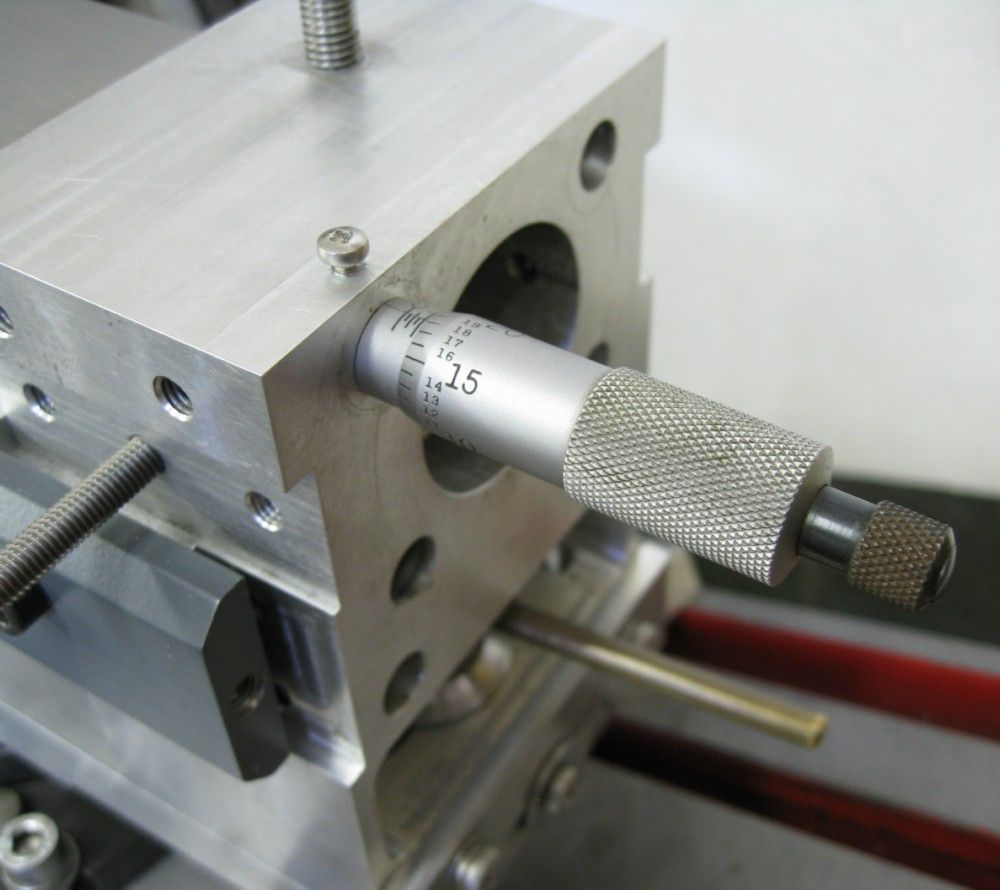

Then I added a micrometer to the drill grinding stage on the grinder to be able to minutely advance the drill to grind the primary facet – I was using the X slide to do that, but with small drills ( sub 2mm) the movement is difficult to keep fine. The micrometer makes it a doddle!

Makes sharpening drills a pleasure!

Joe

Steviegtr.

Steviegtr.

![img_0345[1].jpg img_0345[1].jpg](/wp-content/uploads/sites/4/images/member_albums/178744/821478.jpg)

![img_0346[1].jpg img_0346[1].jpg](/wp-content/uploads/sites/4/images/member_albums/178744/821479.jpg)