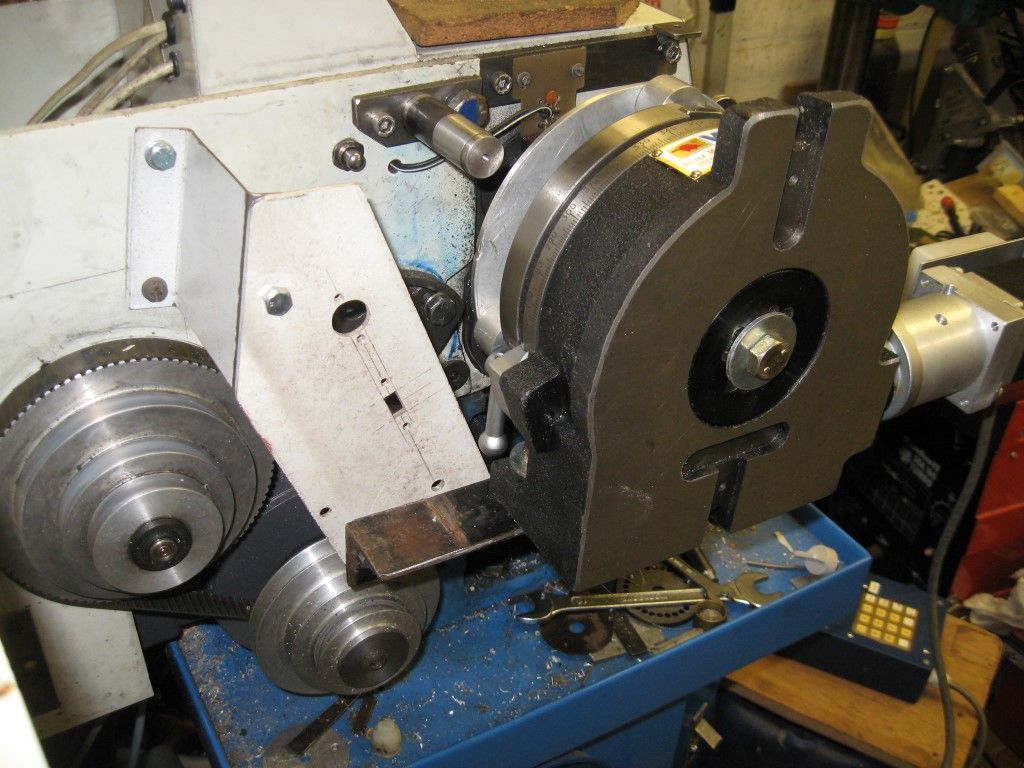

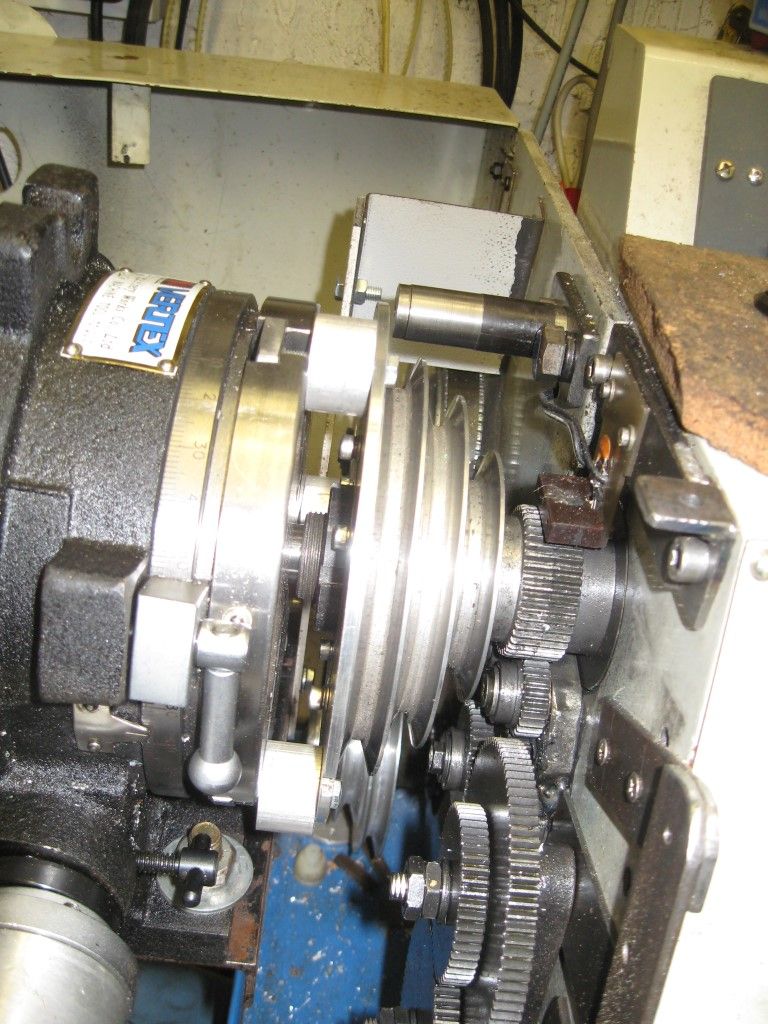

Yesterday afternoon, actually, milled two rows of 12mm diameter hemispheres (37 each side) into a large (by my standards) plastic disc, for the rotor of a model Pelton Wheel, that I am hoping to complete for The WaterWorks Museum in Hereford. It needs to be finished and operative before September when Pelton Wheels will be the feature one week end.

While there on Monday, I repainted the rotor, and sealed leaks, on a small one that originally drove a fan, at a country house. At least that made more sense than using a hot air engine to drive a fan to keep the room cool!

This one was fixed onto a wall, so sadly was rather hidden away from public view.

If you haven't been, its well worth a visit. On summer weekends, they have as many as possible of the engines, steam, petrol and oil, running.

The latest start up is a 9 inch bore Wilson Heavy Oil Engine. Probably the only one left in the world, and took five years to get into running order.

On Monday, the Museum unveiled a plaque awarded by I Mech E for the oldest working Triple Expansion steam engine in Britain. It used to pump water from the River Wye, to supply the city of Hereford, and so is on its original site.

Howard

Tim Taylor 2.