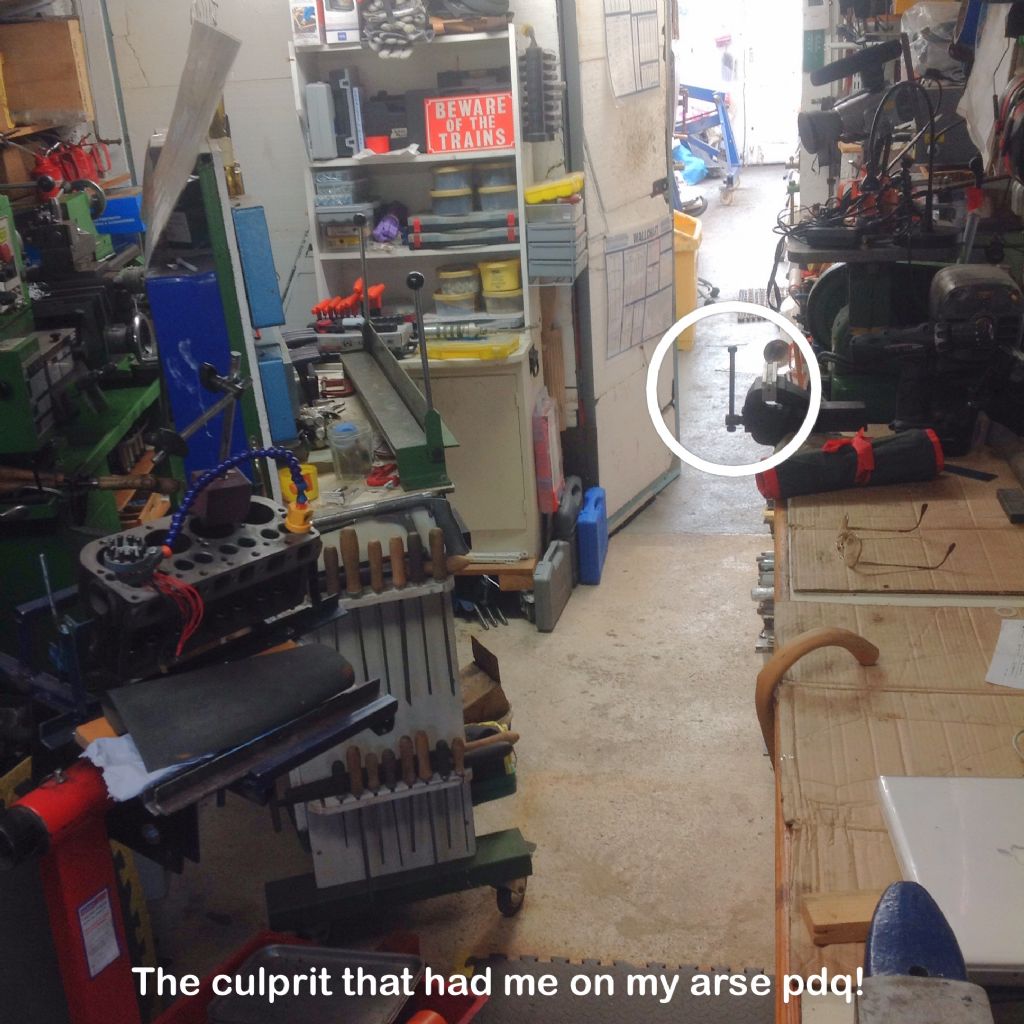

Finished messing with the sump, coolant pump and coolant in the CNC machine. When I removed the coolant pump, it looked as if something very big and very ill had thrown up in the sump.

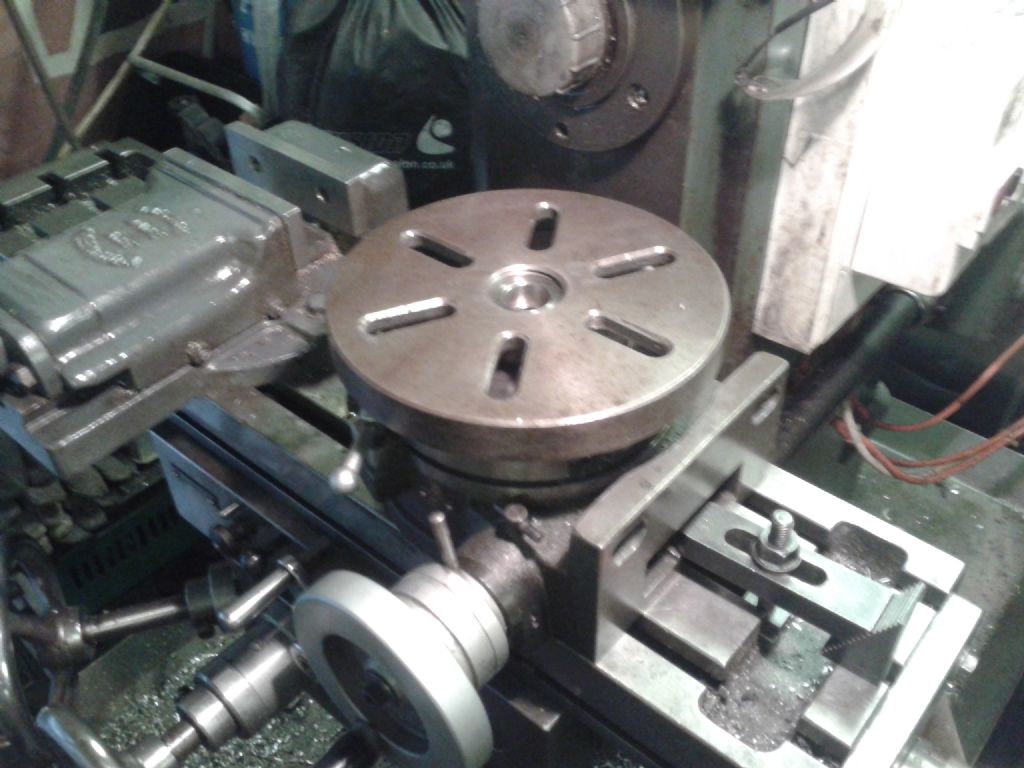

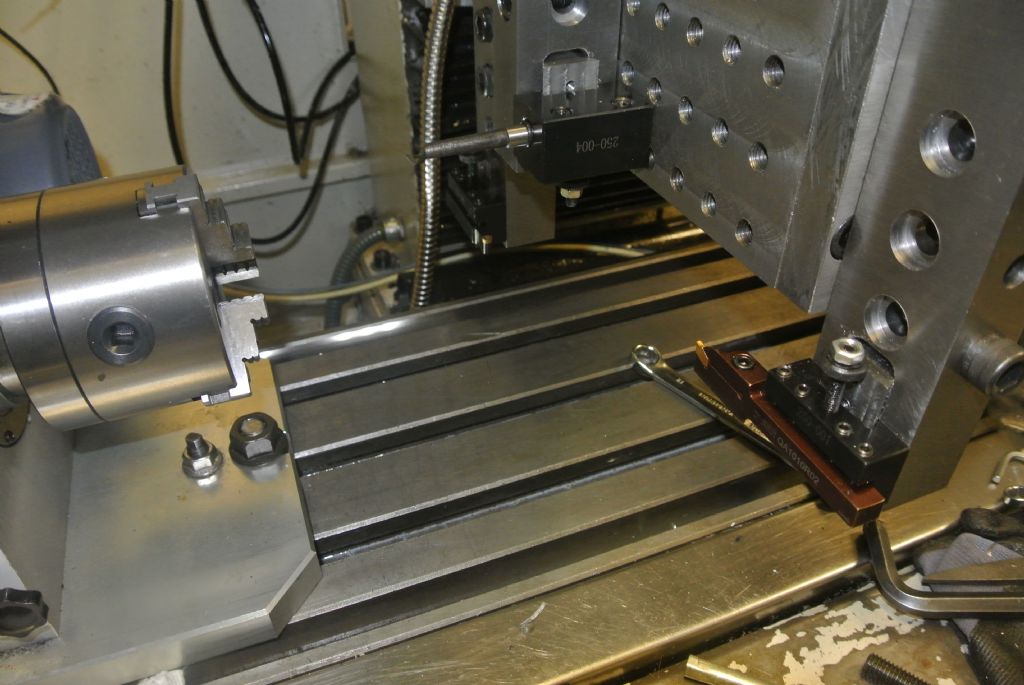

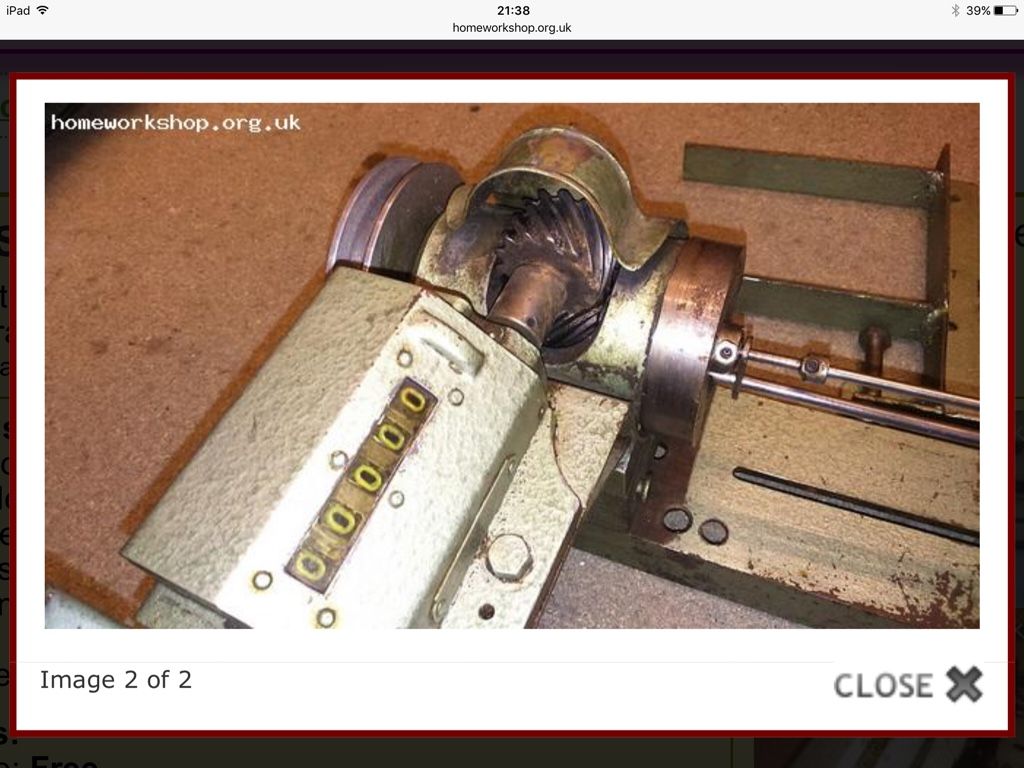

It took quite a bit of flushing and Gunking to clean out all the crap. Now it looks pretty good, so was time to put some new coolant in. This is what you see with the inspection cover removed, looking horizontally into the sump chamber, with the pump aperture visible at the top:

Got some Castrol Hysol XF from Broughton Lubricants who are based not far from my place of work in Preston. Hysol XF is a soluble oil recommended for general machining operations in both steel and aluminium, so should do for my purposes. The choice of lubricants has come up in discussions on this forum previously and when I looked around in the market, Hysol XF seemed to come out well. The main issue being the minimum quantity of 20L. I need about 2L for the CNC machine and even with the lathe and Blidgeport I'll be lucky to use another 2 litres at the recommended dilution of 7%. Ah well.

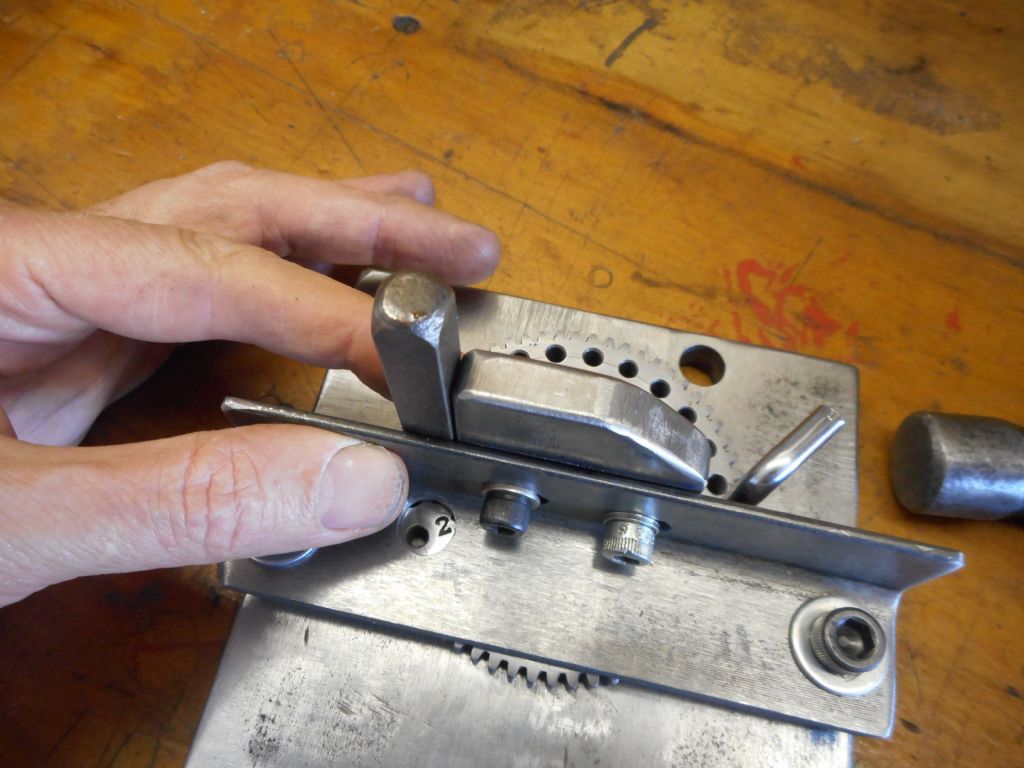

The recommended method to check the dilution is with a refractometer. A simple, visual refractometer is fairly straightforward to use. You place a drop of the fluid on the glass surface and lower the frosted plate onto it. The refractive index of the fluid refracts the light onto a graduated scale in the eyepiece and you can read off the dilution directly. Good explanation here.

The coolant pump is a 3-phase induction machine but I didn't fancy coughing up for a VFD just for that function. And the spindle motor is designed to operate over a wide range of speeds (1000-6000rpm), so not sensible to piggy back the coolant pump off the back of its VFD. Instead, I simulated the third phase using a 8uF motor run cap from Maplin.

This scheme is a bit of a compromise. Once up and running, you could remove the cap but that's a drag, so you tend to choose a value that can start the motor and be left in place without damaging it. The rule of thumb seems to be 70uF per kW and as my motor is 0.1kW, I went with 8uF. A centrifugal pump doesn't present a big startup load, so it isn't a critical application. Works nicely, controlled by a solid state relay (SSR) controlled by the CNC controller. I can either turn it on manually or it can be controlled by the g-code.

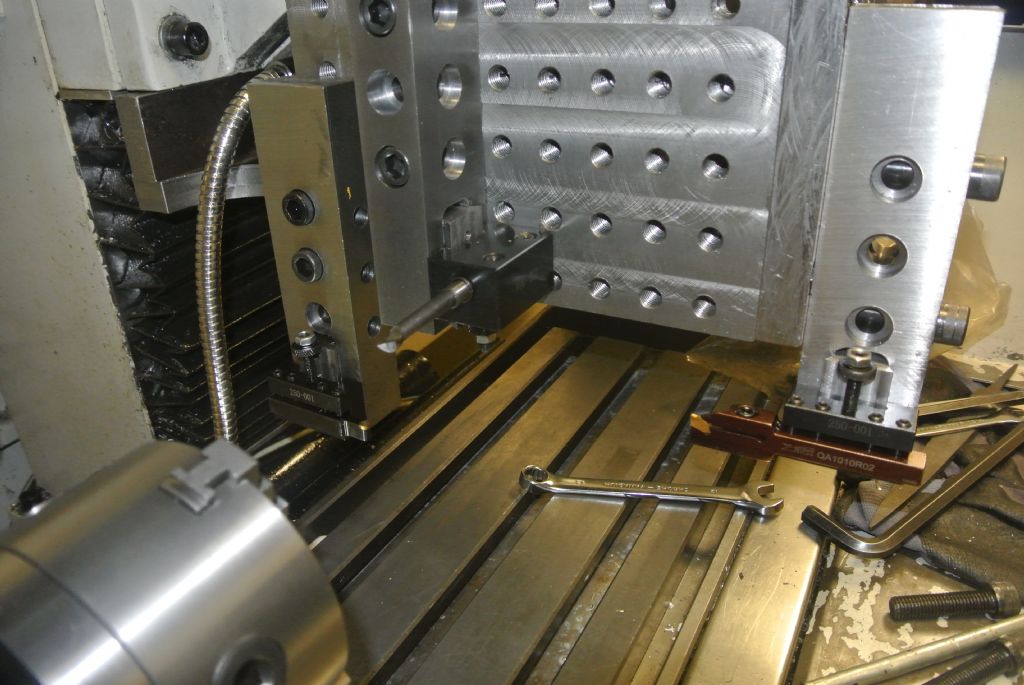

There don't seem to be many parts of this machine I haven't cleaned out or overhauled now and sure enough, the coolant drainways in the table and saddle needed to be cleared out. Lots of steel filings etc.

Murray

Another JohnS.