Decided not to put this on bodgers lodge as not of sufficient interest but more an exercise in making swarf.

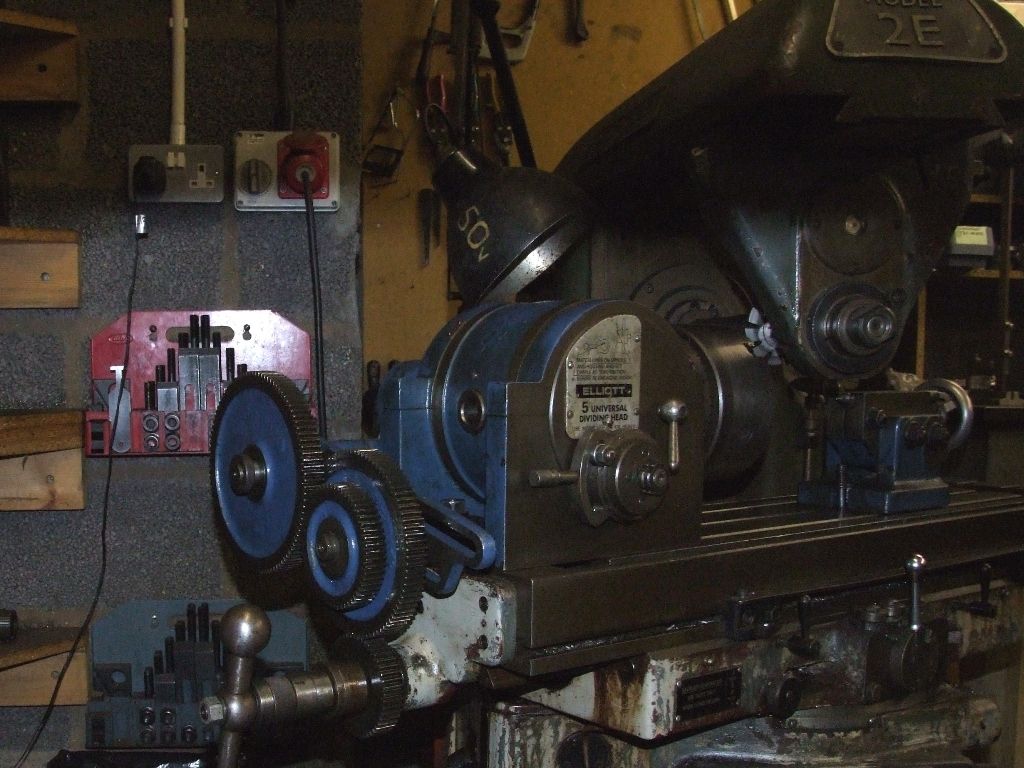

Started off at dinner time today with these two pieces. The ring is 14" diameter and 1 1/4" thick. I trepanned the centre out yesterday to save time and material.

The other lump is 10" diameter by 7" long slug of alloy or rather Billet as it sounds so much more expensive.

The 10" lump wants boring out into a top hat shape with 15mm walls and a 12mm end, then it wants fastening to the ring to make a very heavy duty bell housing for a hydraulic pump to connect to a 20 HP motor.

The off the shelf units are die cast out of monkey metal and they keep ripping the pumps off the motors.

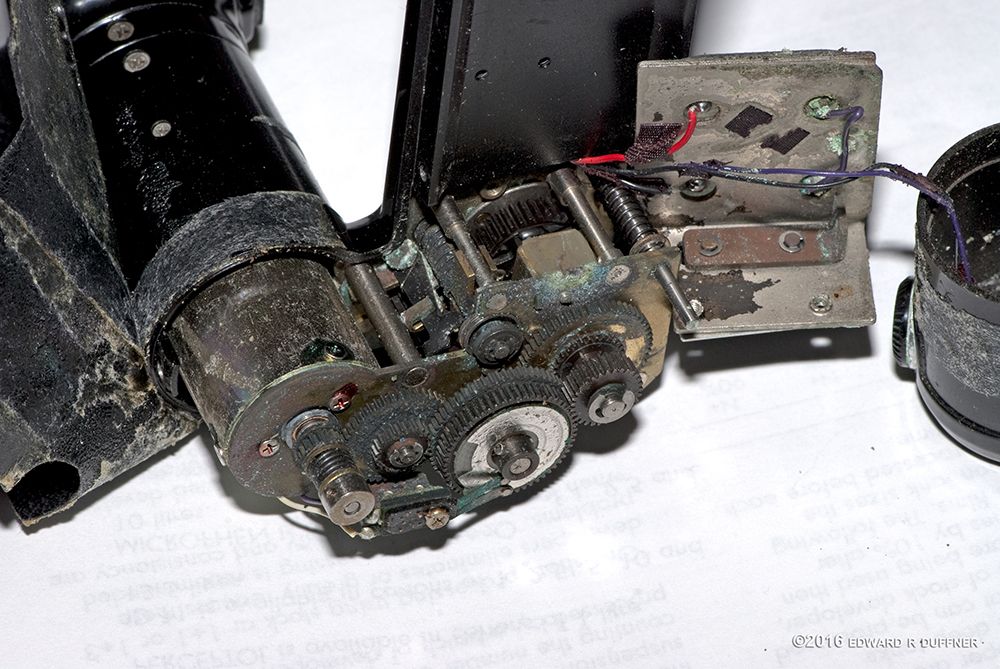

Pretty well there by 3 o'clock and all roughed out but had to break off to repair the fan shaft on the floor in the first pic, it's now got important.

Two bits bolted together by 6 cap head bolts ad a skim on the outside to clean up.

As it's too big at 10" to pass over the cross slide I have had to use an upside down boring bar and run the lathe in reverse to get the reach.

Note the three M16 nuts welded to the soft jaws so I can hold this 14" diameter ring without the jaws hitting the bed. Turned after welding so I know they run true.

Has to do it this way as no one stocks 5849C collets

Knock off tonight at 6 o'clock and this is as far as I can go.

Waiting for the pump in the morning as I think they are going to supply a larger pump than they have been using seeing as this mounting won't bend and explode like the die cast ones and then just needs four M20 tapped holes for the motor.

Pump is easy it's only a register hole and four M10 or M12 tapped holes.

Edited By John Stevenson on 18/10/2016 20:51:15

JasonB.

JasonB.