Ok guys, broken taps and drills…

*EDIT* I've done this by point rather than person as I'm on a laptop with no mouse and I HATE copy & paste editing with the little touch-pad doodahs

The material is EN3B according to the eBay sellers description. Shouldn't be a problem?

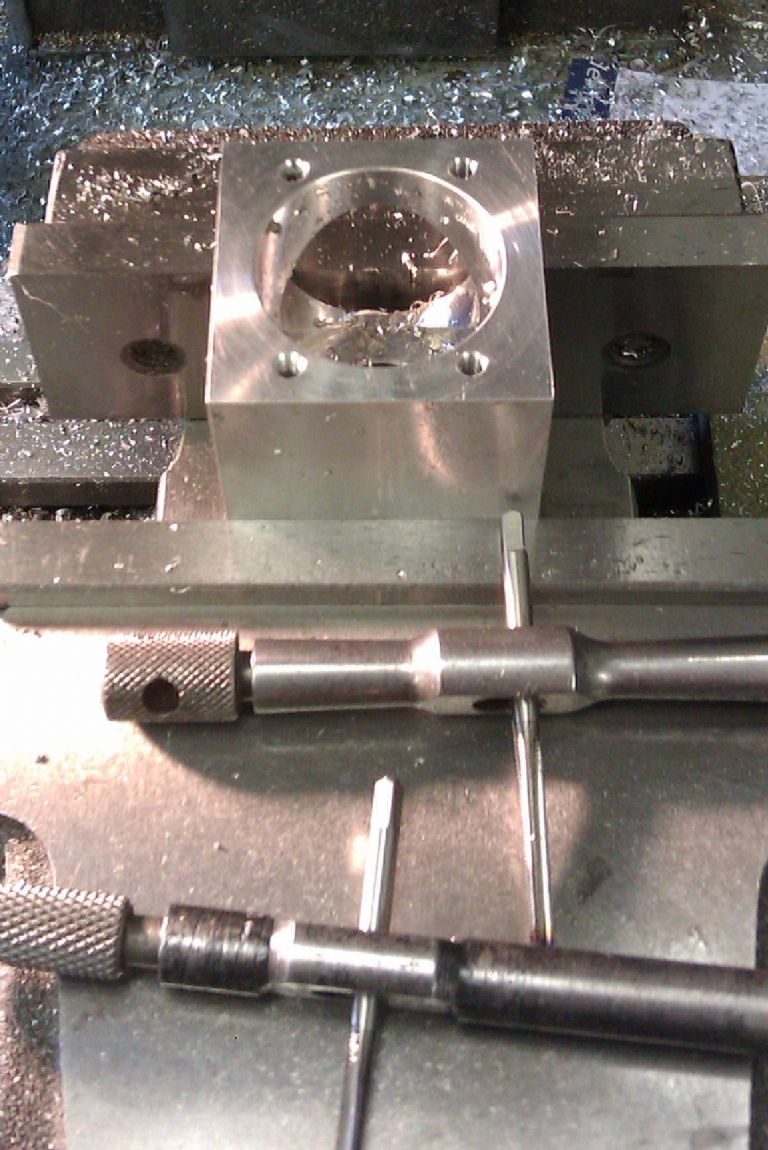

Work order – I went for the approach of marking/punching each hole, then a shallow centre drill (I have no spot drills or four-facets) for each, then 1.5mm drill, then 1.6…. and so on. Next time I'll try clamping the whole thing up more permanently and finishing each hole before moving on to the next. I did consider mounting in the 4-jaw and drilling in the lathe, I guess that would suit/encourage the single-setting approach; Would anyone recommend/consider/avoid this?

Move the hole – I could but I've already drilled the corresponding holes in the frames, as well as marked them all out and drilled the pilot holes for axle bushes etc. ; I did this first then clamped the whole of the framework together to mark the buffers for drilling. The holes appear to be off/uneven (towards the bottom) but that's because the buffer is only 10x20mm square, where the depth of the frames is 22mm so the screw heads will sit even distances from the top and bottom edge.

Drill and tap quality – Hopefully I've addressed this buy buying again, and better. Drill-wise I've gone for a couple of bits from an eBay seller that I previously bought some 6.8mm bits from (for tapping M8, bronze boiler bushes, this went fine) so hopefully they will be up to the job. There is some irony here, my Farther in Law has donated a couple of handfuls of quality drills (mostly Presto, mostly unused) from when he worked at Senior Service in Hyde. Unfortunately they are not the right sizes, in the main, for this project. I have tapped him up (great pun!) for some practical advice here and there but he's not into the subject matter and I think the engineering side of it was just work to him really.

Removing the broken bits – I had a go with the broken drill, and there isn't much left of the whole of the face now, so there wasn't much point in discussing that and it got dumped. For the broken tap, I'm guessing that if it's in an under-sized hole then it might be fairly stuck? So I'm resigned to making new pieces… In itself good practice as the lathe is still set up for milling and IMO the finish was 'adequate' but not really 'satisfactory'. The way I see it is the finish would have done fine for that particular application but not for, say, a steam-chest-valve-seat type of thing (thinking ahead a project or two). I will be posting a separate question in 'Beginners..' about suitable cutters as I've noticeably dulled the one I used… Both ends of it!

Tapping wrench (posh ones) – Other than size, is there anything between them or are they much of a much-ness? Any reason to chose/avoid a ratchet one?

Many thanks to those who have commented, this forum is a great resource and your help, as ever, is very much appreciated. Jason – extra marks for not only browsing my albums but adding pics to threads when I'm not always able to. Though I may start referring to you as Big Brother

Edited By Steven Greenhough on 29/05/2015 21:34:22

JasonB.

JasonB.