I was a bit stupid in my last post. It's an attempt to get a narrow guide with a dovetail bed. Not a bad one really but to work the rear one would need to be a little clear.

I should have looked more before posting –

I should have looked more before posting –  wife was calling.

wife was calling.

So looking at it again

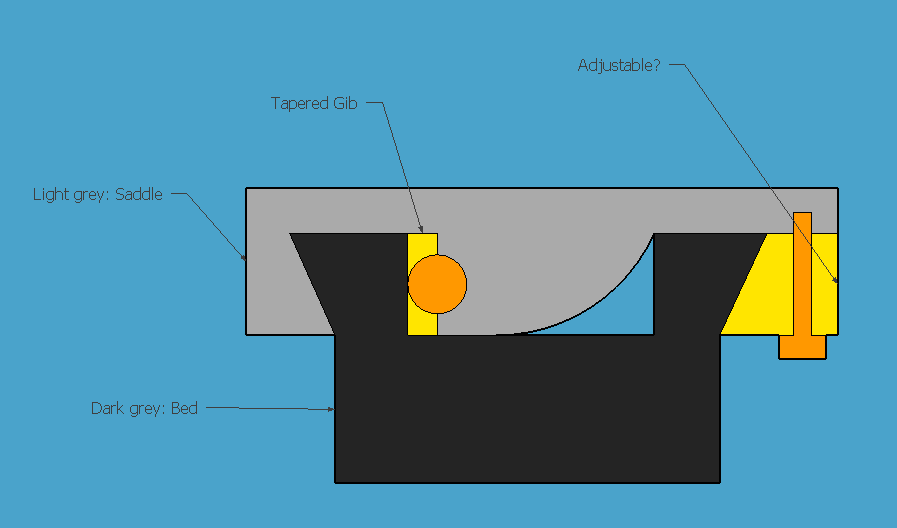

Lets take away the inner gib strip and just use the outer dovetail. If there is a thou clearance the saddle can rock by that much and cutting forces will cause the saddle to pull down onto the bed at the back due to the angle. This is why circa 60 degrees is often used for this sort of thing as it has less mechanical advantage than say 45 degrees. This will increase friction. There has been all sorts of arguments about the ideal angle.

Put the gib strip back and unless the saddle is longer a thou of clearance will allow the same degree of rock but the effect of cutting force is acting on a vertical face. The gib strip also has a very substantial section of saddle behind it to help resist cutting forces far more than the usual rear dovetail has.

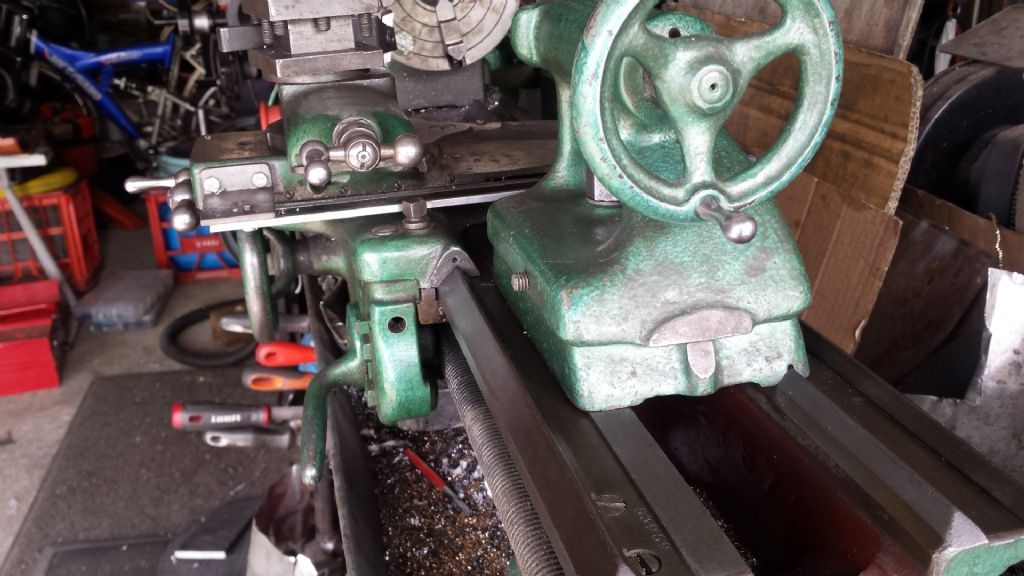

There is another effect that might influence Tubal Cain but doubtful. If anyone has adjusted a myford for how slides out to be they may find that it tightens along the bed. Often there is too much wear to get even close. If they then mic it up they may find that the difference needed to do this was minuscule. Even hard to measure with a tenth reading mic. Temperature can have an influence on that. Unlikely but one of the factors. It also has a different effect when the saddle is moving which is reckoned to be the main advantage of a narrow guide as the forces used should be close to the centre line of the guide – ideally they need to be exactly in line and can be on a prismatic bead. That aspect is a fact. This is probably why he would put things back as they used to be. Also because he would regain the stiffness running along the rear of the front rail. My memory of that is that it really was substantial.

Putting the gib strip inside taking cutting forces looks strange but I suspect it does have an advantage. It will be the part that wears most first so can be replaced. Tapered gib strips are wonderful things to use. They support the gib strip all along it's entire length and are extremely easy to adjust precisely. Some larger lathes have been known to use them and if some one messed about setting one up it wouldn't take long to realise just how superior they are to the usual screws. Pity they didn't add a wear strip to the front dovetail. In fact it's a pity they don't use wear strips in all sorts of places on lathes and other machines. At one point in time some slideway grinding people could add them.

The other aspect about narrow guides is where the cutting tool should be in relationship to them. Smack in the middle of the length is one argument but the real point is that they shouldn't be at the end nearest the chuck as that encourages wear as they can't spread the load along their length. True of any guide. Some bed designs have large flat areas that help to get round that problem. Modern prismatic beds are hardened but it doesn't help in respect to saddle wear.

As drawn there is a significant area taking the cutting forces via the gib strip. Much more than a 7's bed proportional to the size of the lathe.

It's not bad really but would need some changes to make max use of a narrow guide.

John

–

Edited By Ajohnw on 14/09/2016 00:22:36

Ajohnw.

So personally I do wonder if they should have changed that at some point. They did on the ML10.

So personally I do wonder if they should have changed that at some point. They did on the ML10.