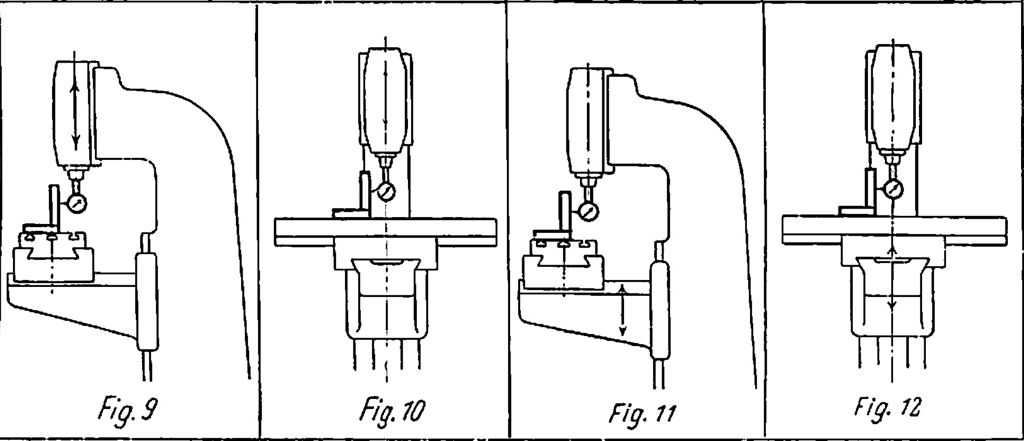

So yeah from that diagram I’m seeing the head being trammed while moving the table up which would be what I’m doing when I move the whole head up and down

Then I see in the diagram moving the quill up and down to also check that.

Now when I move the head up and down if I’m not wrong it shows that my z axis column is fine as I get no more than 0.002″ over about 60mm or so I can live with that.

But as soon as I move the quill up and down its game over 0.015″+.

I understand what every one is saying g.

Is square well square yes I’m sure moving head up and down would show more than the 0.002″ I was getting g if not?.

So I removed that and used the z axis column same issue.

I then made sure spindle is not moving I’m sure it’s not its to stiff to rotate and I did not see any movement at all plus verdict returns to my original zero.

I’m not going to lie this issue is gutting me I’ve saved for a very very long time I just want to make stuff etc.

I will cut some metal tomorrow  and see what I get.

and see what I get.

Thank you to every one for assisting me with this truly do appriciate this.

P.s I’m on me phone and it’s terrible on this forum the window I have to type in is about 2cm big what’s up with that? Lol.

David Standing 1.

and see what I get.

and see what I get.

.

.