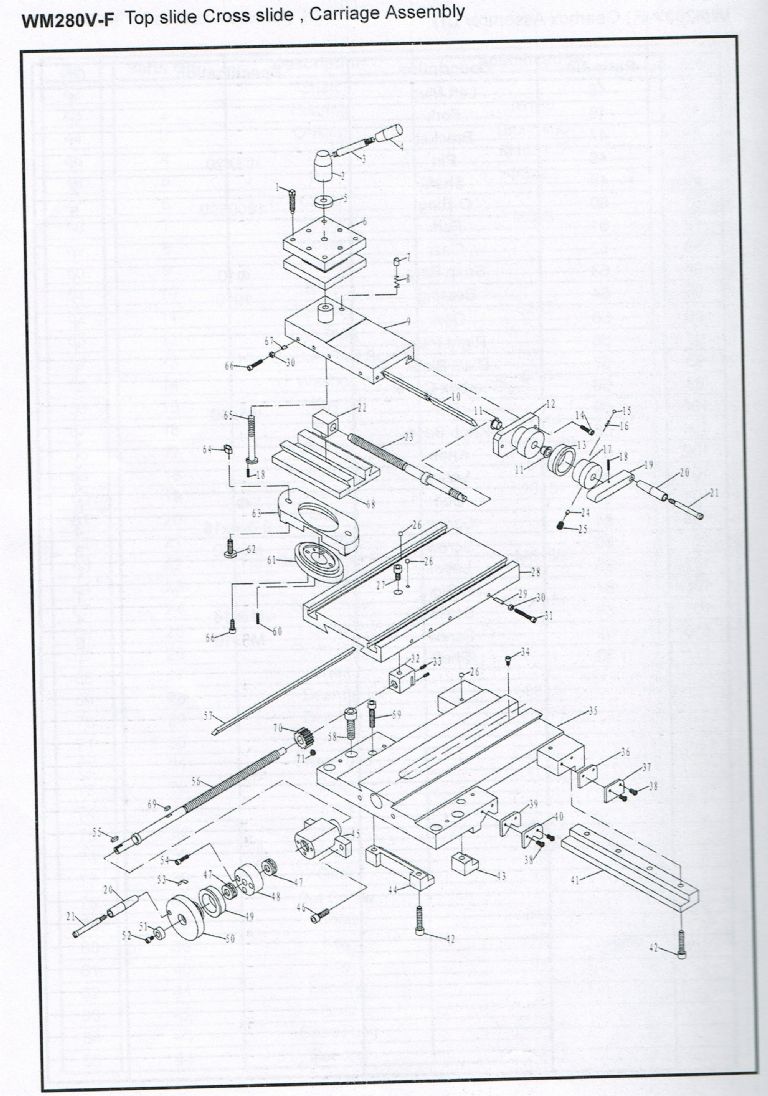

This is how I think the cross slide nut is mounted in my Hafco AL340D (generic Chinese 13×40, similar to Grizzly g0782, etc), and, by extension various other brands/models. In my 'Cross Slides' album there are pages from the manuals for three different lathes, all similar, but not identical. Two of them (the Warco 250 and the Grizzly g0782) are functionally identical. The third, (Warco 280) appears to omit the collar around the nut mounting screw. It may well be correct, although I would be surprised, because it would mean that the nut placement would be even more critical.

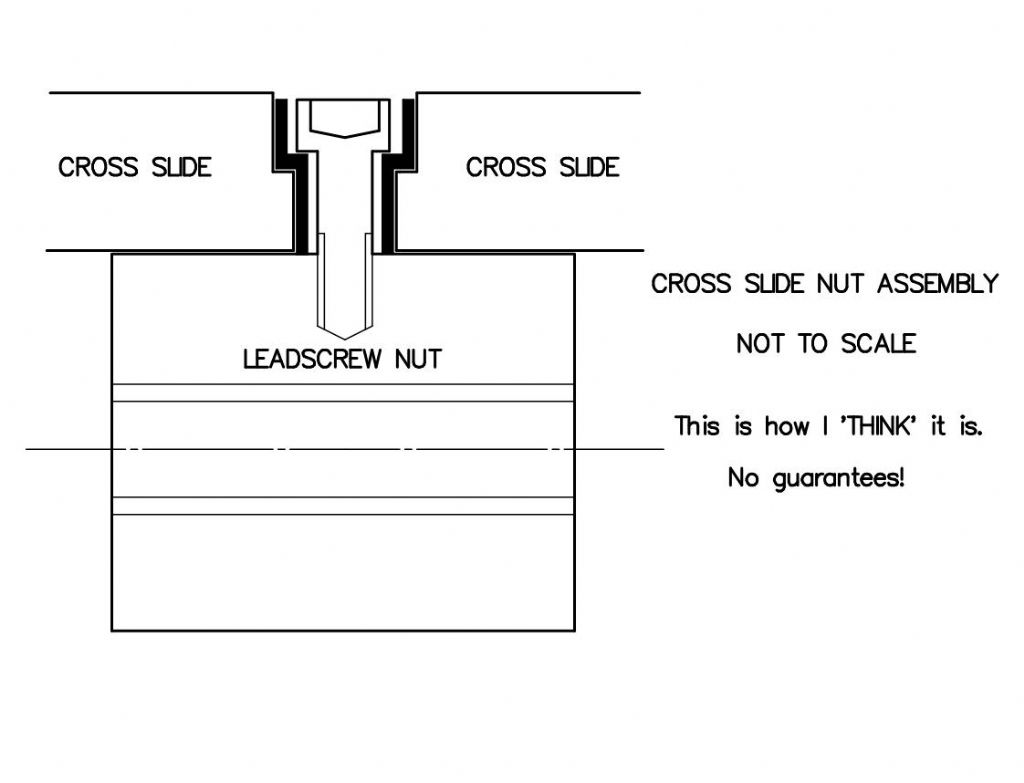

How it works: The image 'xslide nut.jpg' shows the arrangement in my lathe. The collar in the parts diagram doesn't truly illustrate the shape (sort-of an inverted top-hat), and that makes it hard to vizualize how it works. The collar is a very neat fit (< 0.001"?) in the counter-bored hole through the cross slide, and the bottom half (the smaller diameter section) is minutely (~0.001"?) longer than the thickness of the section of the slide through which it goes. The result is that when the bolt is inserted and locked down into the nut, it (the nut, bolt, and collar assembly) is held to the cross slide but is free to rotate about the vertical axis. This is good from the point of view of coping with a slight bend in the leadscrew (in the horizontal plane, although it doesn't handle it very well in the vertical plane), but in itself it isn't sufficient. The reason why is because the position in the horizontal plane of the leadscrew front bearing is invariably not exactly in line with the nut position on the cross slide. This condition is catered for by making the hole through the collar larger than the diameter of the bolt, so so that the nut (and, of course, the bolt) can be positioned off-centre before being locked to the collar. That adjustment is made with the cross slide fully retracted i.e. with the nut as close to the leadscrew front bearing as possible.

It certainly works very well on my lathe. The collar is 20mm diameter and the M8 bolt has ~1.1mm of movement available within the collar. Movement of the collar in its recess isn't visible to the naked eye, but the change in light reflection from an oil meniscus at the joint can be seen when changing cross slide direction. It's a feather-light movement.

Looking at the WM250 image it looks like the lower half of the collar that I have illustrated is actually formed as part of the leadscrew nut, and I assume the collar is basically a cup shape. It would all work in exactly the same manner, but it seems an odd way to make the nut. Edit: Not quite the same; the collar part formed on top of the nut would need to hug the bolt and have the movement clearance on its outer diameter. [/edit]

If the WM280 image is correct, it would seem that there is virtually no tolerance for misalignment or distortion of the leadscrew. Maybe the parts diagram is incomplete, and it is in fact similar to the above?

Edited By Roger Head on 06/11/2015 07:55:01

Roger Head.