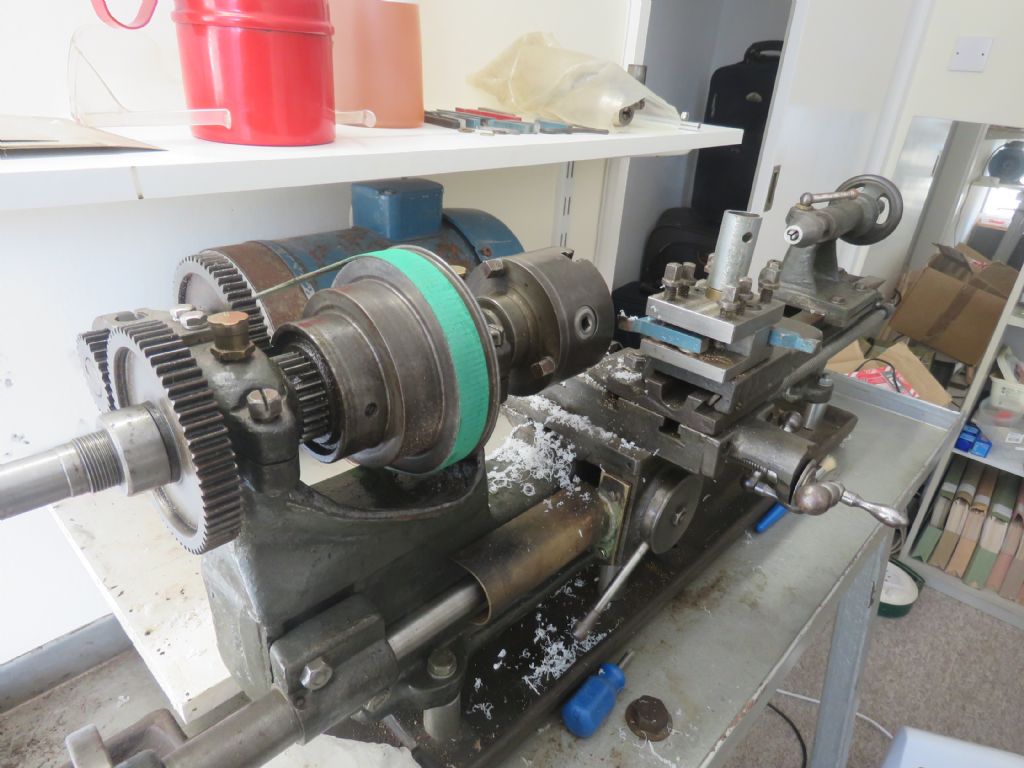

For a machine of that vintage, the nuts are very likely to need Whitworth or BSF spanners, not Metric or A/F..

The threads wiil probably be BSW or BSF, with possibly BA for things like gib adjusters.

You need to distinguish between slack and backlash

Backlash is wear between leadscrew and nut, and unless there is provision for reducing backlash, such as split nut, short of making new parts, there is not much that you can do about it. You just learn to take out the backlash as you use the machine. (If you overshoot, back off by more, at least twice, than the backlash and then advance to where you want to be )

If there is play between the handle and the cross slide, if possible the handle can be moved along the Leadscrew to close the gap. If the position of the handle is fixed, by a pin, the space can be filled with one or more washers, or even better, a custom made spacer. Which you can make on the lathe!

For this lathe, if Imperal, as it seems to be with a 16 tpi leadscrew, you need to work in inches and thous, to make life as simple as possible. Try putting on a cut of 0.02 mm using a dial with 125 graduations, let alone 62.5!.

If you want graduated dials, you will have to add them. (Whjch means making, or finding some kind soul in your Model Engineering Club who will make and fit them for you) You certainly won't find any "off the shelf".

A dial for a 16 tp[i leadscrew will need 62.5 graduations to give 0.001" increments. "And a Half"?

Yes! I made one for my Adept Shaper. It looks a bit odd with 62 evenly spaced marks and then a half size gap, but that is what it takes, unless half thou graduations turn you on. For those you would need a larger diameter dial to accommodate the 133 marks with a sensible spacing. The wider the spacing, for a thou, the more accurately you can estimate lesser parts.

Probably essential on a machine with plenty of backlash.

Howard

.

Roger Best.