Posted by Andrew Johnston on 01/11/2019 11:43:40:

On the assumption that the machine didn't vibrate when new the question is why is it doing so now? Poly V-belts may be better, but they're a red herring while the source of the vibration is unknown. A few ideas are:

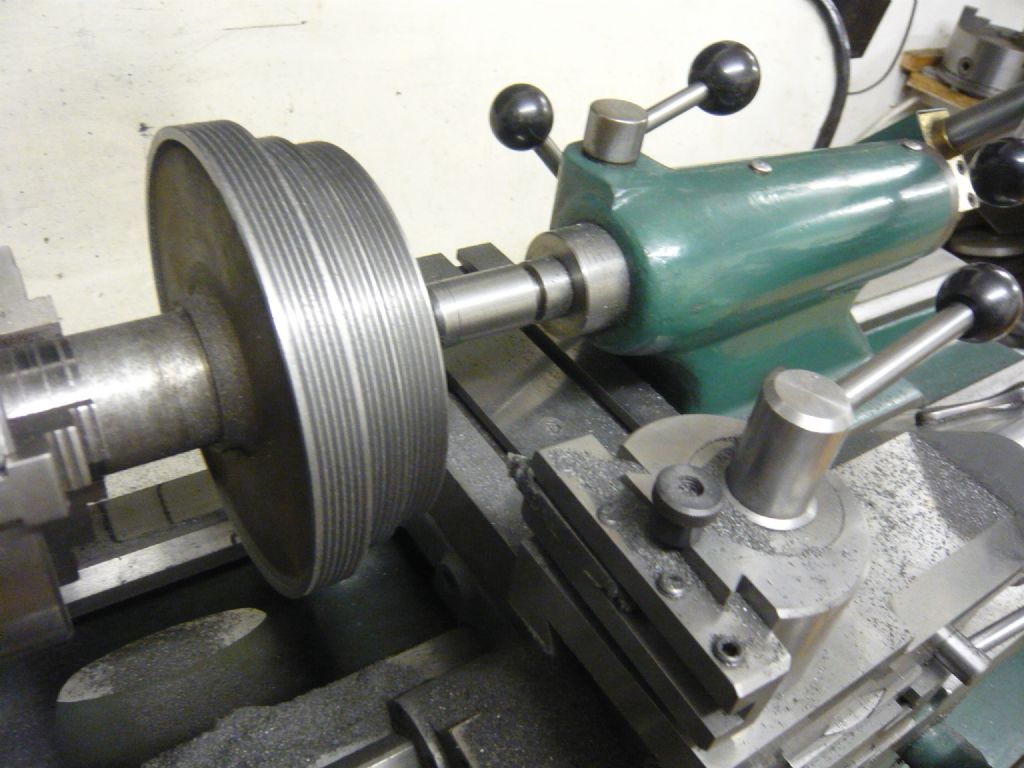

A 10mm deflection for 10N (1kgf) force seems pretty slack to me, especially on a long unsupported belt. None of my V-belt driven machine tools have a vibration issue, and none of them have idler pulleys.

The second belt looks a bit odd; is the top pulley in line with the intermediate pulley or should the belt be one pulley further out at the top?

While it's unlikely to be the problem a single phase motor is not as smooth as a 3-phase one. It might be that the pulsing characteristic of the single phase motor is exciting something it shouldn't.

Would we be correct in assuming that the vibration only happens when a cut is in progress? If so what is the feedrate? A good starting point for chip load is 4 thou per tooth. When I started using my horizontal mill I used a much smaller chip load, and the whole machine vibrated. My horizontal mill weighs nearty two tons.

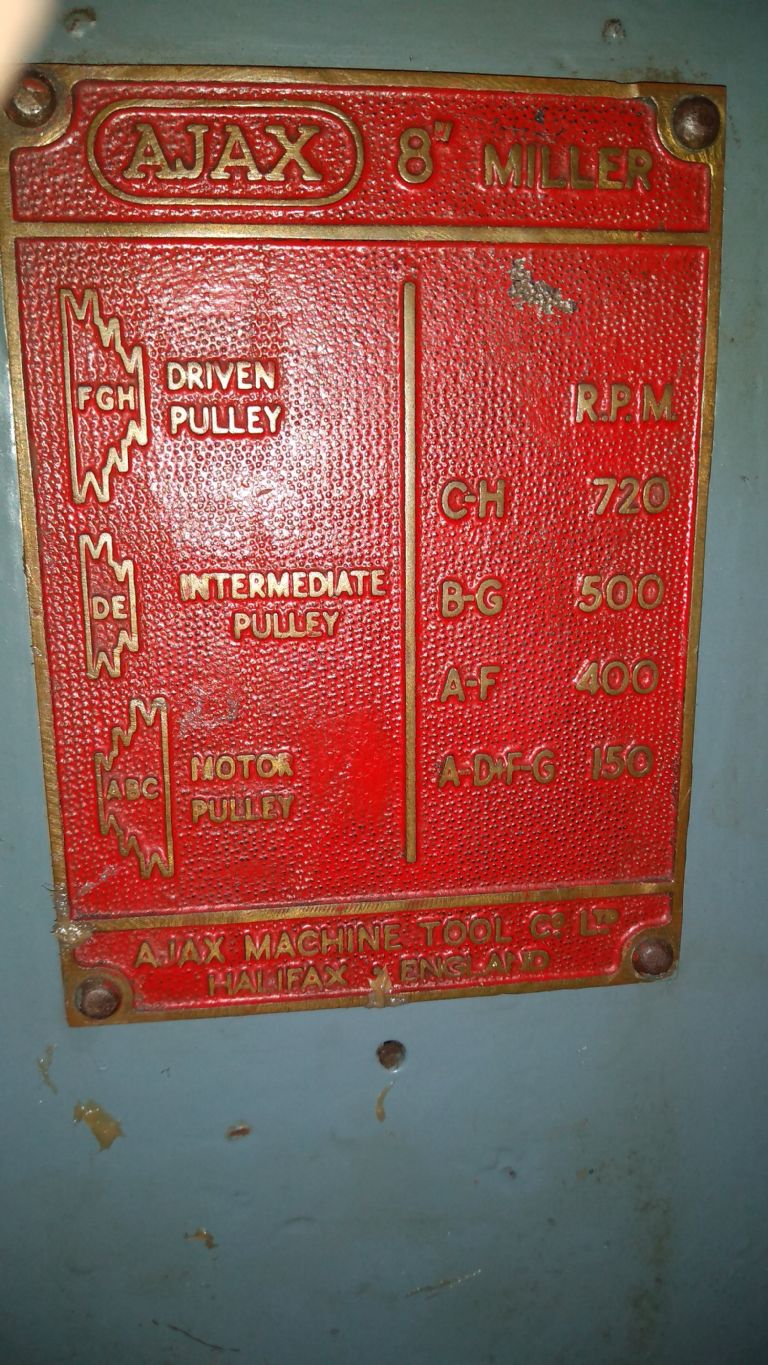

What rpm is the cutter running? Looking at the speed chart the lowest value of 150rpm is on the fast side for a 5" cutter in steel.

Andrew

If the current setup allowed a small increase in belt tension I would do so, but as you are now aware there is no means to do so other than changing the belt. Rightly or wrongly, I feel the belt tension is about right apart from the problem of belt vibration/oscillation at higher speed which I'm starting to believe is due to other problems (e.g. feed rate or unsuitability of the cutter).

I doubt changing to a 3 phase motor will fix this problem but I'm happy to convert as I already have a spare VFD. It might also give me some flexibility over spindle speed that I lack through the very limited pulley options.

Regarding the current setup, the pulleys have been chosen to give the slowest spindle speed and best belt alignment.

The vibration only happens when taking a cut using the full width of a 5 or 6" x 1/2" cutter. I have *many* cutters that were included with this mill but most of them are clearly too big for this machine, including slab mills, etc. However, I have enough smaller cutters to know that I can take decent cuts with no vibration. I should point out the 5 and 6" cutters work well (with no vibration) when I can progress the machining on the y axis taking no more than about 2mm at a time.

I will probably be getting rid of the unneeded tooling in due course. A couple of items have already been sold, so the machine has only cost me £60 plus the motor mount purchased new.

The speed chart is something of a red herring as the motor and motor pulley are not original. 120RPM is about the slowest with the current setup and I now understand that may be somewhat high for a larger cutter on this size machine.

Thanks for all your help,

Brian

AJAX.