My mini lathe has blown up. I was happily chewing down 2 1/4″ EN1A blanks to 7/16″ wide for loco wheels. Not working it hard at all really, no more than 25 thou cuts. Big pop and motor loses a couple of windings, and the machine had been cold up until a few minutes earlier.

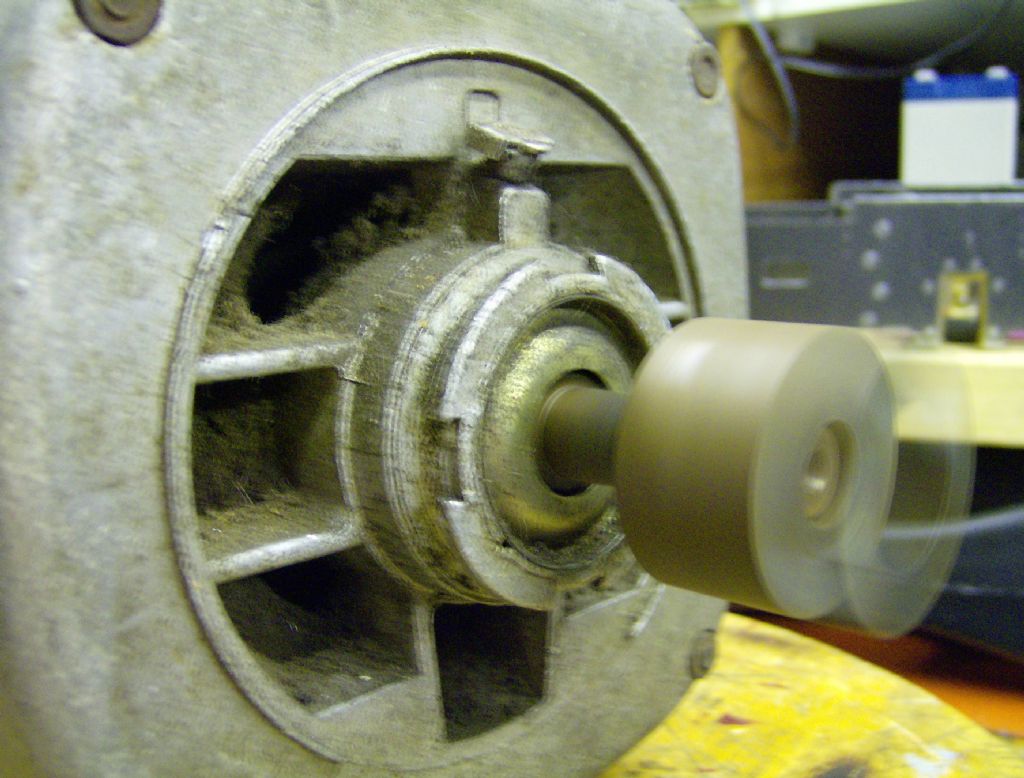

I discovered some swarf had got into the control box and bridged a few connections beneath the comparator board.

In the hope of rapid recovery I did the very naughty trick of bridging the bad coils with solder on the commutator, it worked OK on 12V, if a little rough.

The blow terminated my resettable 1A cutout, which I replaced the fuse with.

Put it all back together and … motor didn’t turn, just popped again very loudly. I should have taken advice elsewhere on this forum and tested with a light bulb.

Looks like the board is putting out 216 V when it is at minimum speed.

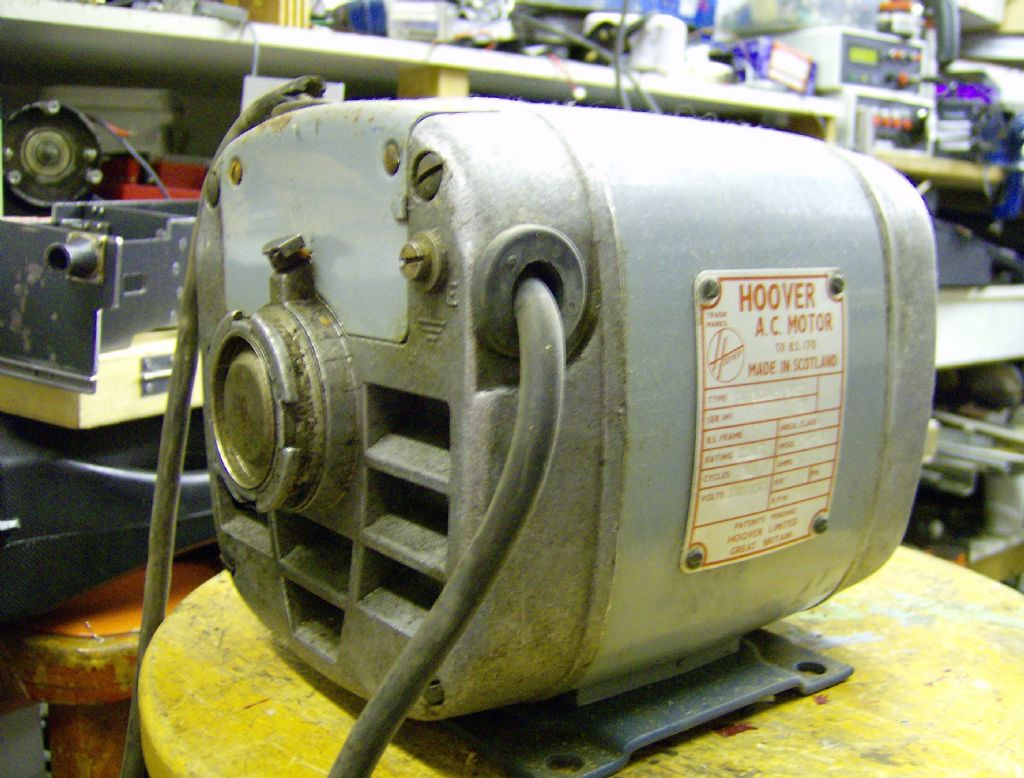

There may be something to salvage, but right now I’m wondering where to find the groats to get a 0.5HP three-phase motor and inverter pack. Not a good time as next month is Christmas and MOT all together

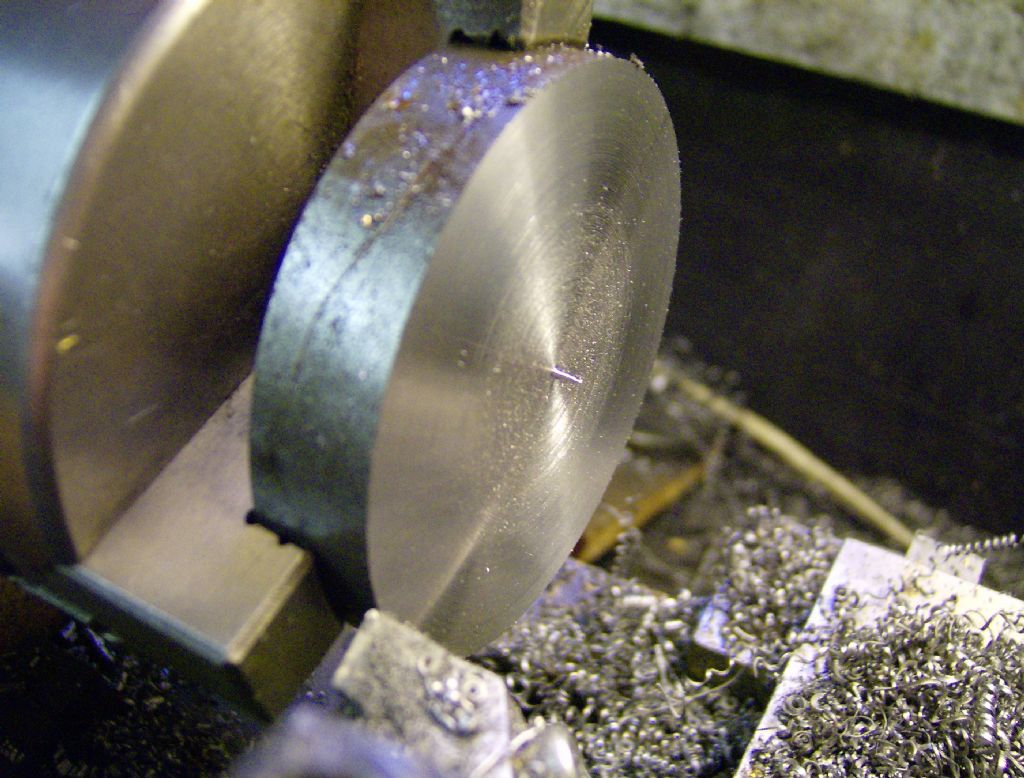

Biggest annoyance is that the tangential tool holder was giving me a near mirror finish on that nice steel – best I have ever got.

Neil

Richard Parsons.

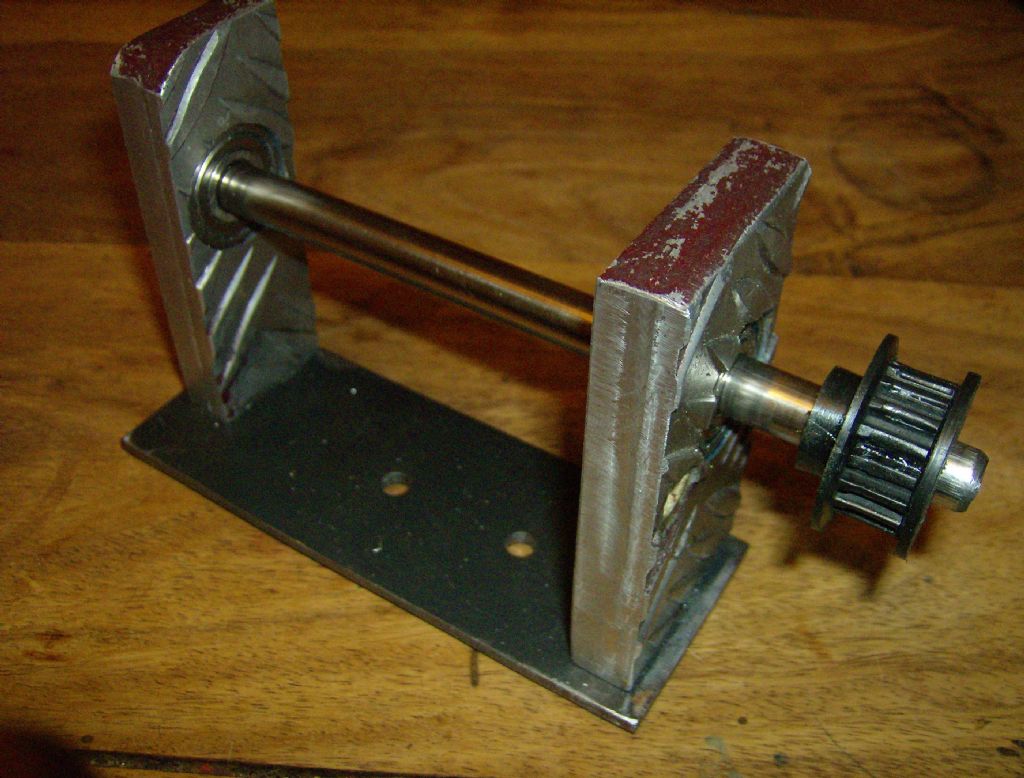

. I was back ‘on-air’ two days later.

. I was back ‘on-air’ two days later.  I had made a note of one of the forum ‘regulars’ being a county neighbour and wrongly attributed it to Neil.

I had made a note of one of the forum ‘regulars’ being a county neighbour and wrongly attributed it to Neil.  Just have to keep taking the tablets, I suppose.

Just have to keep taking the tablets, I suppose.