Is it the enclosed gearbox version or the exposed bevel gear version?

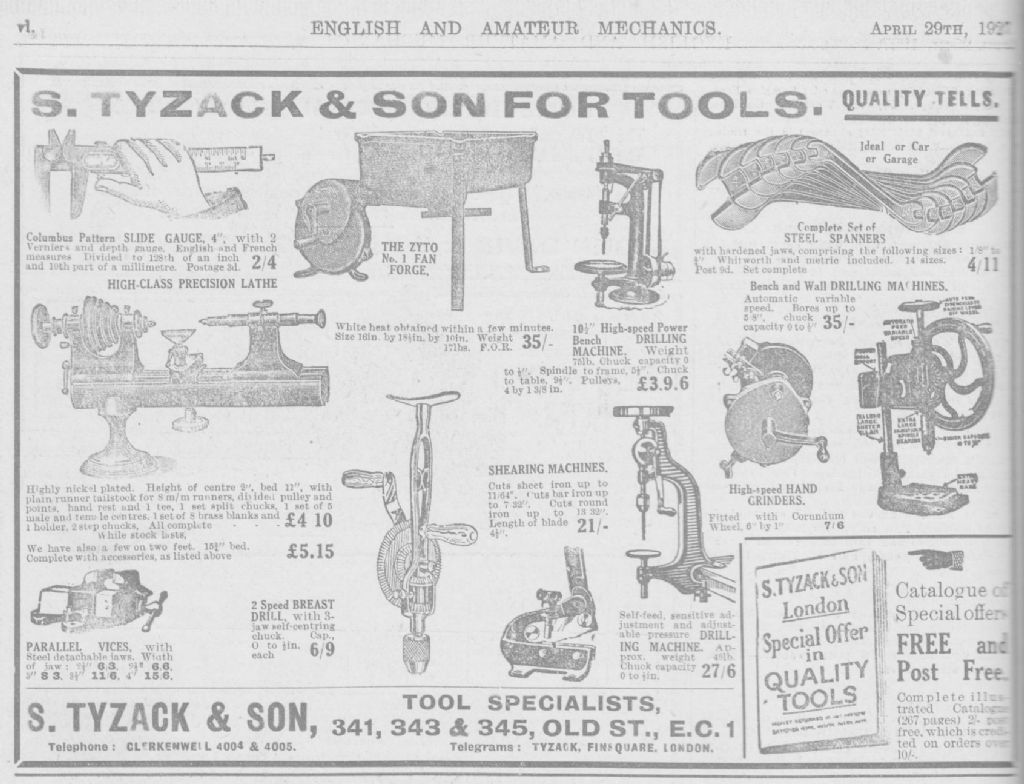

Exposed gear one has a bevel gear on the main drill shaft and two bevels on the handle drive, one large one small. There are two bearing holes for the handle spindle. Put the handle spindle in one hole to engage the large bevel with the gear on the shaft for high speed. Use the other one for low speed. Usually a a wire spting clip passing through a hole in the casting and engaging in a groove in the handle shaft to keep things in place.Not sure if Tyzack actually sold this type under their own name.

Enclosed gearbox type has two square shafts sticking out the side with fit the drive handle. One is high speed, top I think, the other is low speed. usually top one is high speed. Drill shaft is driven by a bevel. Low speed drives bevel direct from the handle, high speed via a step up gear train. There was a thread including pictures some time back.

These drills have an automatic screw feed driven by the inertial drag of the flywheel on top. If the thumb screw is close to the top its probably the drag adjuster which sets feed power. Cant remember whether more drag is for more or less feed.

Both types are same as equivalent "gut buster" large hand drill types. Probably used same components.

Clive.

Edited By Clive Foster on 23/03/2017 08:48:56

JOHN LEWIS 9.