Posted by Iain Downs on 17/09/2017 09:40:43:

…

The references provided by Nick are very useful, but what I would like to know is 'I want to face some aluminium, which tip should I use?' Or 'I want to get a good finish on some steel', or 'I want to part of some brass' ….

I get that you can work out sizes and stuff from the numbers, but why would I pick this rake angle or that tip radius?

Most of us have a lathe in a certain size and power range – surely it's possible to have some simple recommendations of which tips to use for what?

My approach at the moment is to buy something from ARC or other suppliers and hope it's general purpose enough…

Iain

I've not found a simple answer to the question, rather a mass of guidelines aimed at experts! I think the fundamental issue is that manufacturing is about cost, and managing it involves factors irrelevant to small scale operations. There are several trade-offs well worth the effort in mass-production that result in a multitude of alternatives.

I've not found anything that links insert types simply to these various trade-offs. What follows is what I've gleaned. I don't know that it's right and offer it in the hope that someone more knowledgable will correct it!

The two main factors that matter to a cutting tool are the rake angle and the relief angle. And the effect of rake and relief also vary with cutting speed and depth of cut. These factors interact will the material being cut and tweaking them is more-or-less advantageous depending on how hard or soft the metal is; for instance copper is very soft compared with chilled cast-iron.

The rake angle determine how 'sharp' the tool edge is where it hits the work. More positive angles are 'sharp', negative angles are 'blunt'.

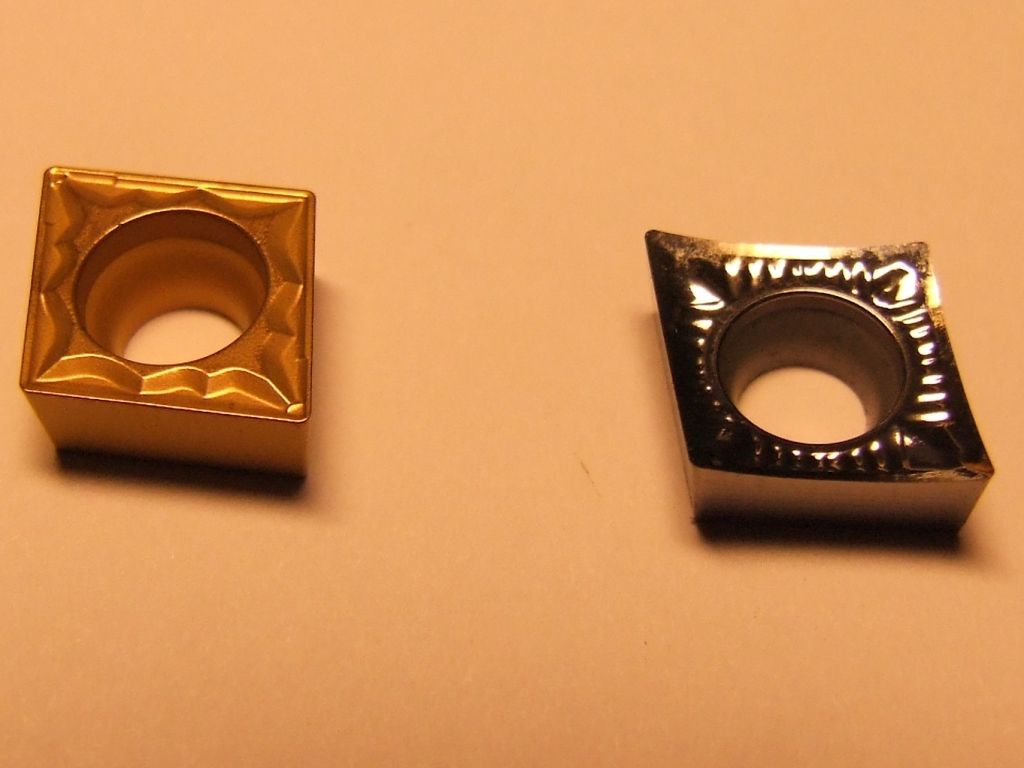

- Positive rake is better for 'soft' metals. (In this context, Mild and low carbon steels are at the hard end of 'soft'.) So use a moderately positive rake on most steels, and make the rake progressively sharper i.e. more positive for Brass, Aluminium and Copper. Sharp tools are not good for taking deep cuts, but are better for finishing.

- Negative rake is used for very hard metals, for interrupted cuts (like rounding the corners off a square plate in a lathe), and for roughing. Negative rake inserts are often better value than positive ones because both sides of the insert can have cutting edges. Also, in industry, deep fast cuts with a blunt edge uses less energy to remove metal than a positive rake insert.

Relief angle seems more to do with finish, and the ideal relief angle also depends on the metal being cut. The idea seems to be that the tool should rub slightly just after the cut to smooth it whilst allowing space for swarf to escape. In practice the relief angles of inserts vary between 5° and 14°. 5° relief angles are used on hard metals like stainless steel, and 14° on soft metals like Copper. Relief angle doesn't seem to be very critical, and an insert with 5° to 10° relief should do most jobs.

Bottom line on this is that the bewildering range of possibilities may not matter much to the average home user. I've found that:

- 'Sharp' high positive rake inserts recommended for Aluminium work well on mild steel and brass at relatively slow cutting speeds producing ribbons of swarf.

- The Moderate positive rake inserts of the type easily available from Arc and others are good for mild-steel and equally effective on Brass and most Aluminium Alloys intended for machining.

- Fast heavy cuts with negative rake inserts are impressively good at removing steel quickly. The swarf comes off as a hot spray of chips not ribbons.

More important I think, than choosing the 'correct' insert is having a machine tool fast and powerful enough to exploit carbide. On a smaller machine (<2000 rpm and/or <1HP), I think you'd be better off with HSS. That said, I suspect an ML4 cutting with the sharp inserts designed for Aluminium, might do perfectly well on all the usual metals.

I think not needing to cater for Industrial optimisations explains why many of the hobby suppliers only stock a small subset of carbide inserts. They are the type having Rake and Relief suitable for 'average' work and they can be expected to do a good job in most circumstances. I used them exclusively on a mini-lathe with good results. On a bigger machine it's more obvious that other shapes of insert are useful but I'm pretty sure almost everything I do could be done with the small subset I started with. (I mostly turn mild-steel, aluminium and brass; sometimes stainless, cast-iron and graphite (with HSS); never Copper.)

In conclusion, I suggest 'ordinary' inserts are fine for most hobby work, and it's not worth worrying about the rest unless you're planning something special. Professional use is a different ball-game entirely.

Dave

Edited By SillyOldDuffer on 17/09/2017 12:54:24

mark smith 20.