Posted by Russ Bulley on 31/03/2020 20:58:38:

…

To SOD good point, but why is the tapping drill size way off the table? I still don’t understand this tolerance as all I want is a standard thread medium fit!

…

All good stuff guys. So where do you obtain the true machine use data …

Russ

I have a number of reference books. They vary a bit depending on the target audience, for example a tool-maker or draughtsman might need all the gory details, a professional might need a few fits, while the amateur wants to keep it simple.

The Model Engineer's Handbook (Tubal Cain) is a good basic reference. He gives one figure for 7/8" BSW tap – 19.5mm.

I have a Newnes Engineer's Reference Book which is a bit more grown up. For 7/8" BSW tap drills it suggests:

- 47/64" for a Class A (Close Fit),

- 3/4" for a Class B (Medium Fit), and

- 49/64" for a Class C (Free Fit)

Tubal Cain recommends 19.5mm for Model Engineering. That's 0.768", rather looser than a Newnes Class C Free Fit ( 0.7656" )

Another good book (second-hand) is Machinery's Handbook from the USA. Mine is the 20th Edition, which does US, British and Metric. 2480 pages of light reading! It recommends a 19.25mm tap drill for 7/8" BSW ( 0.7579" ), which lies between Newnes Class B and Class C fits. Machinery's is lightweight on BSW, obsolescent in 1975, but it does detail on Metric and Unified Screws.

So variations in the Engineering literature! Where did your table come from? It's not unknown for mistakes to creep in.

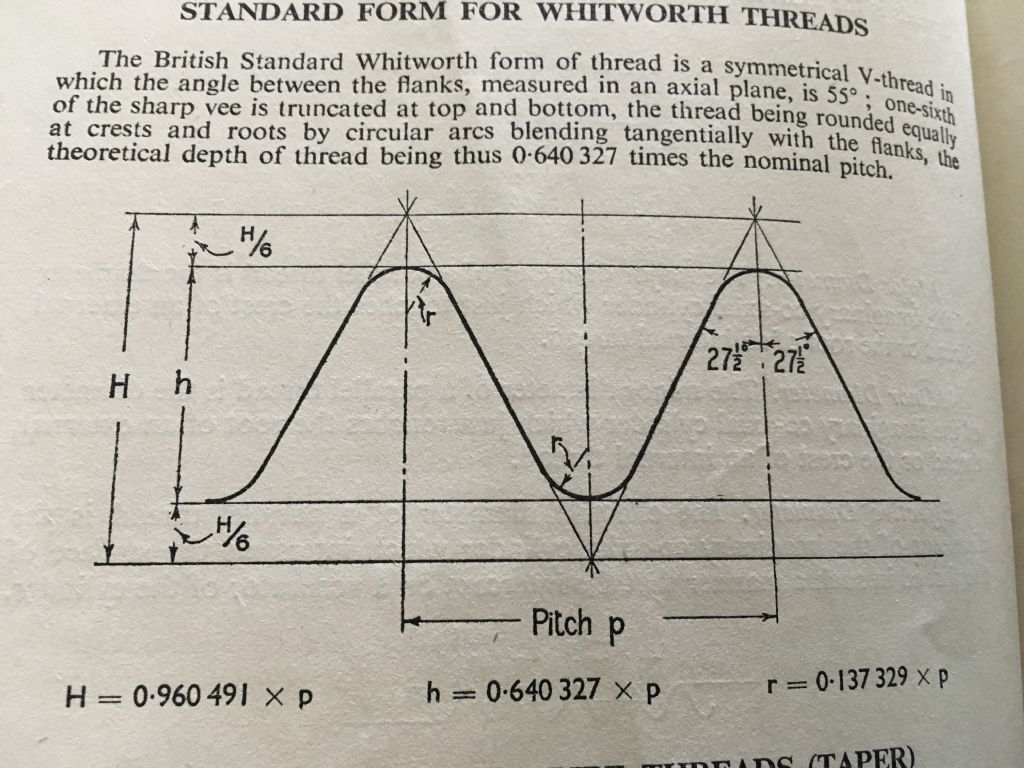

As others have noted, a BSW thread made fully to specification would have rounded valleys and peaks. However, it's common for lathe cut BSW threads to ignore the rounded top, and for the operator to gently flatten the tips off with a file. In the USA they decided Whitworth's rounded top didn't add much value and simplified NS by specifying a flat top. Metric did the same.

What this boils down to is how important the fit is; what's it for? A safety critical thread will be made to a high-standard but for many ordinary purposes threads are made slack. Loose threads are preferred when ease of assembly matters more than maximising strength. In practice, most fasteners are on the slack side.

The tolerance thing is confusing. They're specified for inspection purposes. When I make a batch of threads it rarely matters if some are tight and others loose. As long as they fit together I'm happy. Not so in manufacturing, where interchangeability matters. Gauges are used to confirm threads are made within tolerance, ie not too big or too small for some defined purpose. Machines are set to make threads within a tolerance band, and readjusted as the tools wear, and again when the tool has to be changed. Although the resulting threads can be a long way off perfect, the variation is under control and acceptable within limits. Few of us need to work that way.

Dave

Edited By SillyOldDuffer on 01/04/2020 14:34:38

S.D.L..