Posted by Old School on 29/07/2018 08:49:29:

Jason, Thanks for the info, I won't have a problem with the chuck unscrewing Myford 254s. I am going to try and make some taps to hopefully solve a problem with leaking taper seat glow plugs on our racing. The glow plugs threads are undersize and this might be part of the problem. I am going to make undersize taps as part of the solution.

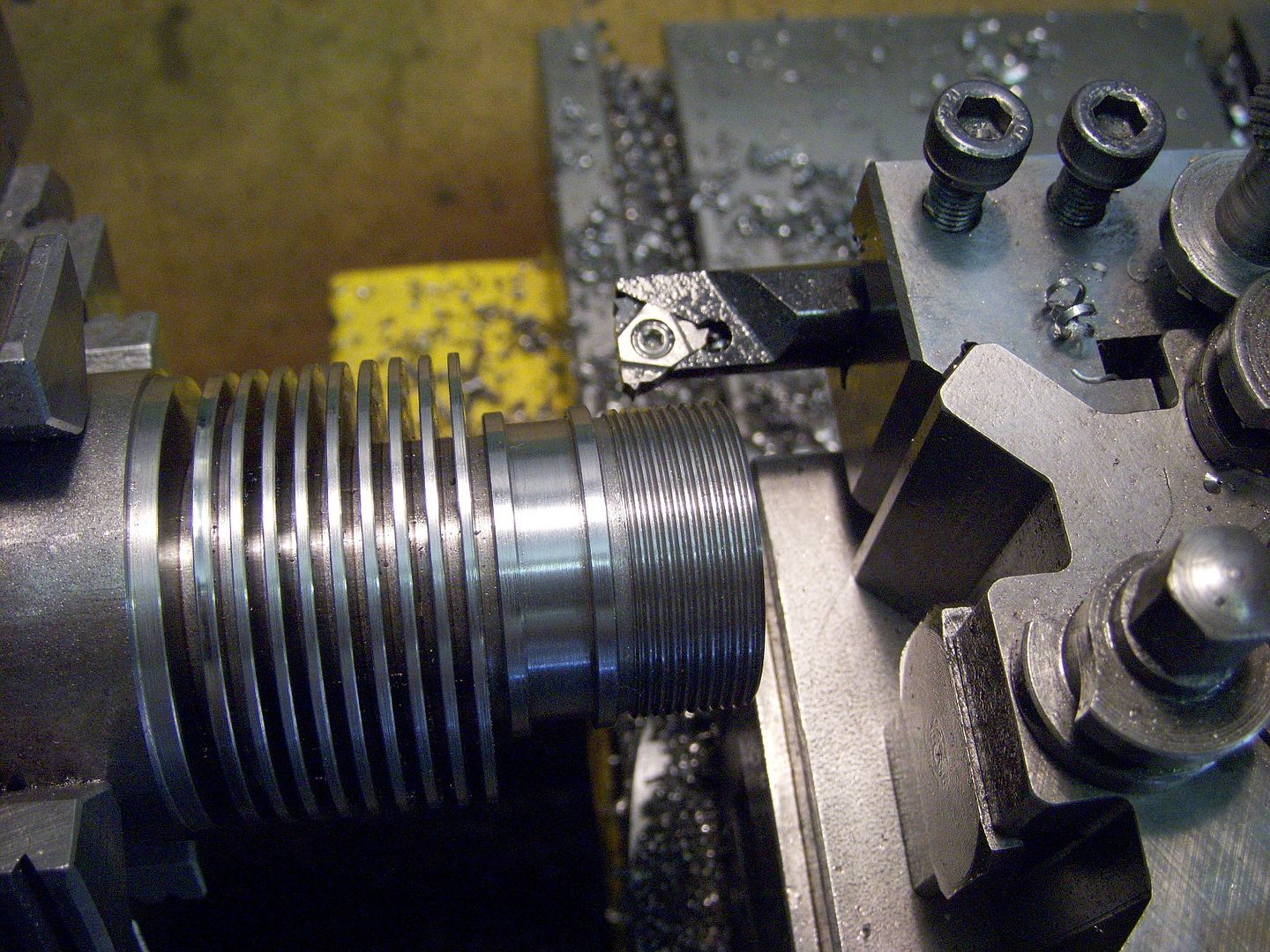

The problem you have is that the thread needs to be concentric to the taper seat in the head insert. If you make your heads, bore the inner diameter for the thread form, and turn the taper seat angle as well. Then use a small threading tool to screw cut the thread form. When it is mostly thread cut, you can use a tap to act as a thread chaser. If the tap is run just straight down the drilled hole, often the tap does not start concentric to the hole. I also found, that if the taper seat angle is made a very small amount, tighter on the front, over the nominal angle. I make the Nelson taper seat 34.75 deg instead of 35 deg. With the Turbo plugs, I make the taper 60.5 deg included angle. With bearing blue, the plugs will seal on the very front of the taper seat. Some glow plugs the seat is not concentric to the thread form. Those plugs will always have sealing issues. You can also correct a head, by making a precision thread form and use that to get the head insert concentric to the thread. Then rebore the taper seat.

SInce setting up the myford S7 with a VFD and a micro switch to stop the spindle, it has made doing internal threading quite easy, with confidence to internal thread cut.

John C.