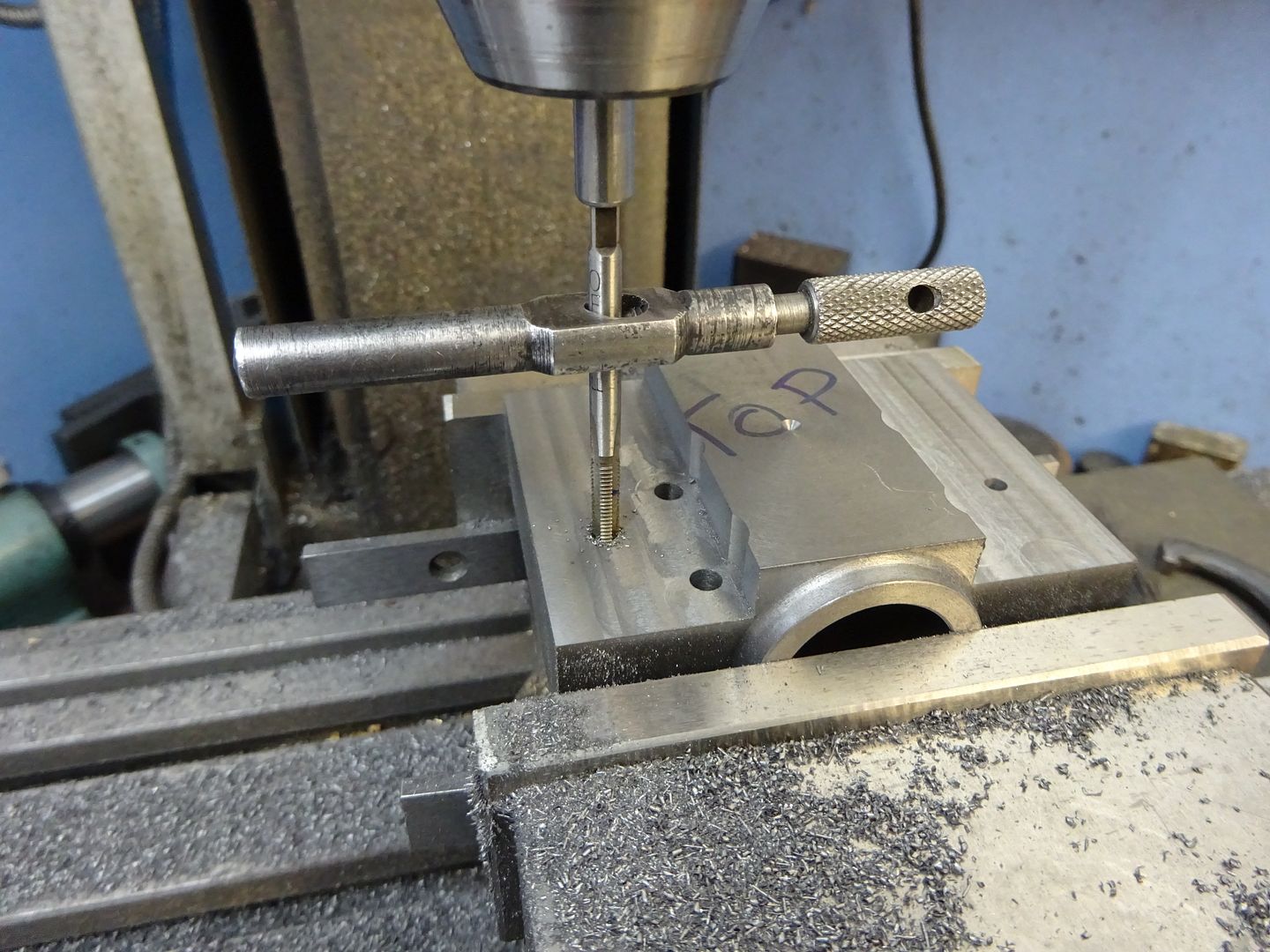

Once, I was told that a lot of taps break because they dislike being subjected to bending.

Consequently, I have made / bought a variety of devices to hold the Tap square to the job. Some are drill chucks that locate in the Morse taper in the Mill – Drill, or Lathe Tailstock. One is a spare drill chuck on a spindle mounted oi what was once the stand for a pistol drill, (A very poor imitation of the G H Thomas Pillar Tool)

Even with ER collets, (A home made ER25 collet chuck sliding on an arbor held in the Tailstock) if the tap tries to stick, the chuck will slip around the plain shank, rather than break the Tap. (That ALWAYS happens in the very last hole in the job!!!!!!!).

For Metric threads, the rule of thumb for a tapping drill is (Nominal size – pitch). If in doubt drill slightly oversize.

My advice, FWIW, use plenty of lubricant, (Trefolex, Rocol STD, or even Bacon fat), and do back off frequently to break the swarf and prevent it packing in the flutes.

My preference is HSS rather than CS since it seems less prone to breakage; or maybe it's just my clumsiness? S

I try:

Not to use a large Wrench on a small tap, but to try to match the size to the tap.

To use both hands on the wrench, or as a Tee wrench, to minimise bending moment on the Tap

If in ANY doubt, to remove the Tap frequently, and clear swarf from the hole by shaking / blowing / banging the work on a piece of wood/ clearing with matchstick or scriber.

Ignoring my own advice cost me a M10 first cut tap! Fortunately, I was able to remove the broken stub, so most of the harm done was to my pride.

My favourite Tap for M6 is a spiral flute, because it cuts at one pass (so less risk of my heavy hands breaking it!)

Risking calamity; since using the various Tapping Aids, have not broken any Taps; (not even 10 BA) but now, that may not last for much longer!

And I thought I was alone in being told off for dropping swarf around the house! Obviously SWMBO does not like sparkly carpets.

Howard

MW.