Sorry if this is going to be a bit long winded.

I recognised my Crusader Lathe was turning tapers so time to readjust. I've done the two-collar method and got that under 0.01mm over 15inches and then decided to have a go at following Harold Hall's method of making a test bar to adjust the tailstock.

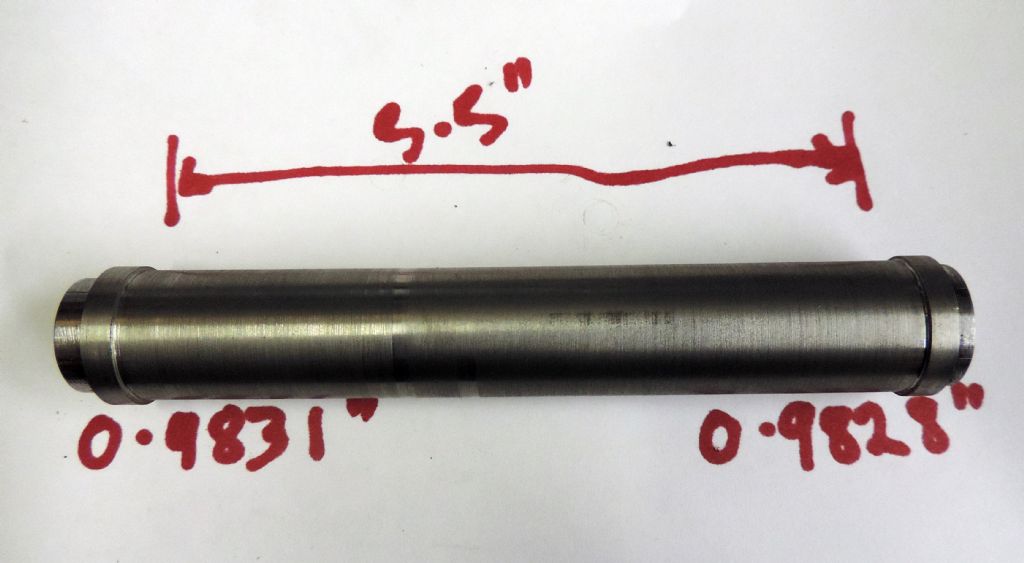

To make the pilot centre drill holes i set my raw 300mm long 1" bar clamped vertically in the angle of a 6" angle plate on edge on the mill.. used an electronic edge finder to find the centres and drilled.. so chould be close.

Mr Hall's article uses the 3-jaw to hold one end with tailstock support.. face as close to centre as possible and turn a 12mm length to 22mm, flip and repeat then set a steady rest at tailstock end and redrill a larger centre.

What worries me is that flipping and using the 3-jaw doesn't guarantee that the two machined sections are concentric and that one has to grip the bar in the turned section so there is no clean diameter at the chuck for setting the steady fingers and the other methods of setting a steady that I've come across: using the tailstock, using a DIY tailstock 4-jaw support or even a mag base DTI on the chuck all (seem to me) to depends on a clean bar round surface or an aligned tailstock?

I guess I'm missing something?

The only way i can see of achieving concentricity along the bar length would be to use the 4-jaw, skim say 1.5" of an inch diameter bar , set the steady then keep extending the bar towards the tailstock with repeat indications and skimming to the same setting until it's length is achieved. At least each section should be concentric with every other and the steady would be set correctly? Even then whatever method one uses to centre drill cannot guarantee to be in the centre if the tailstock is misaligned except if one depends on the drill being pulled to centre by the bar?

Perhaps one should try to set a centre drill in the toolpost and eyeball it to the bar centre as would would a turning tool or even drill a greater angle than a centres 60deg to try and have a point fixing each end as opposed to seating the centres within conventional centre holes?…perhaps a small centre ground stub drill on centre for the pilot would be better?

Advice needed….please.

pgk pgk.