Posted by Andrew Johnston on 31/05/2020 17:33:50:

Posted by SillyOldDuffer on 31/05/2020 17:27:34:…

If there's a need for repeatable accuracy………………….

Repeatability and accuracy are not the same thing. Generally the former is easier to achieve than the latter.

Andrew

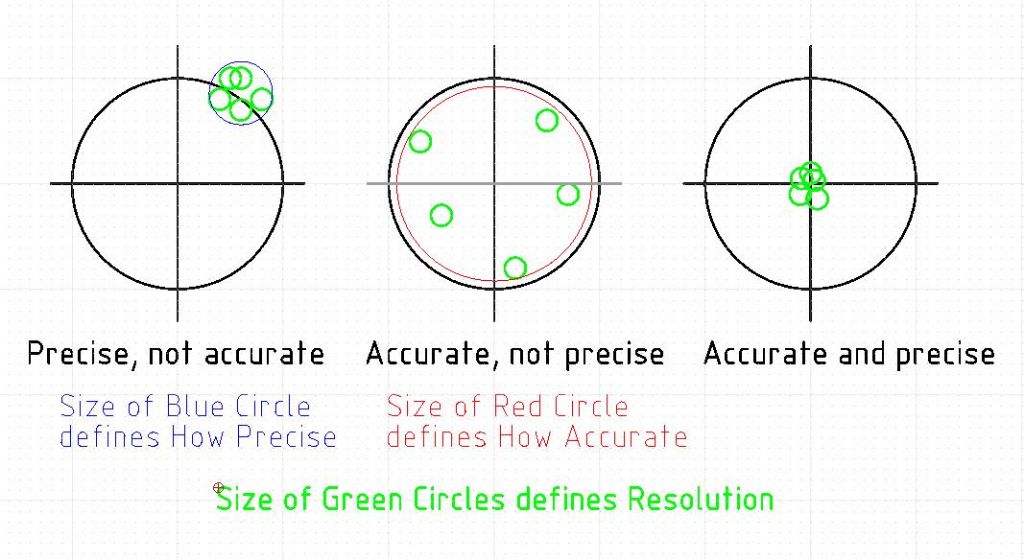

Quite right! I hope it's correct, but this diagram shows how I remember the difference between accuracy, precision and resolution. Using a bulls-eye target to illustrate accuracy and precision came from Neil Wyatt I think. I've added resolution. Apologies for the colours; red's fairly obvious but blue isn't good on my screen.

Resolution is how finely a particular instrument can read. It's not the same as the graduations, which are often over optimistic. However, assuming the operator has a good touch, successfully avoids parallax, and corrects for temperature, the resolution of a 0.001mm micrometer is limited by the state of its threads and anvils. The instruments ability to measure down to 0.001mm is compromised as it wears. Not possible to repair worn threads and anvils in a home workshop, and the professionals rarely bother either. It's cheaper to replace. Serious measurement requires ruthless reduction of all sources of error, and having a good looking but untrustworthy instrument laying around is asking for trouble. Calibration rejects are one source of ebay bargains.

The diagram represents the actual dimension with cross-hairs. Ideally measurements would hit the bulls-eye every time but it's impossible. Minimising measurement errors gets progressively more difficult and expensive. Consequently engineers should be mindful that good enough is good enough. Time and money is wasted on a grand scale when quality is pursued without justification.

The picture has three examples.

On the left bulls-eye, the instrument gets close repeatable results but is persistently off target. It's precise, but not accurate. Not bad news though, because the error might be due to incorrect zeroing, and in any case precise measurements can be corrected by calibrating the instrument. I wonder how many forum members working to better than a thou bother to correct their micrometer readings, or even need to? But calibration and subsequent correction of readings is certainly necessary for serious measuring!

The centre bulls-eye shows an instrument scattering measurements around the target. On average the instrument is correct but its individual readings are all untrustworthy. This is typical of practical measuring, and it doesn't matter provided the scatter isn't too big for the purpose. The instrument is accurate but not precise. Again, the scatter matters for serious work, but how many of us take the trouble in our workshops to average several readings before proceeding?

The bulls-eye on the right is measurement heaven. The instrument reads accurately and precisely. But note that none of the measurements is spot-on. Magnifying this chart shows it has the same character as the central diagram, but the instrument is better because it measures with less scatter. Unfortunately this kind of performance is expensive to buy, tricky to apply, and expensive to maintain. Screw micrometers inevitably lose precision and accuracy because they wear slightly every single time they're used. For that reason serious micrometers are checked periodically against standards and dumped as soon as they exceed specified tolerances. The gauges used to check micrometers also wear, making it necessary for them to be regularly checked against even better standards and replaced too. At the top of the tree is the standard metre, defined from the average of several high-end atomic clocks. There's an enormous gap between the standard metre and my £30 micrometer! Fortunately for me, a £30 0.01mm micrometer is 'good enough' for my purposes, and I don't need to apply any of the disciplined methods made necessary by working to close tolerances.

When buying tools I feel it's important to separate utility from desirability. Understand your reasons. On the down-side, a £30 micrometer looks and feels cheap. There's no pride of ownership in it and having to use it carefully wastes time! My workshop meets my needs but it wouldn't suit a time-is-money professional or the type who enjoys 'quality' tools.

But please don't tell beginners struggling to start on limited money that only the best will do, especially if the best is second-hand, condition unknown, and is over the top. There's a great deal of fun and education to had from imperfect equipment, and one can always upgrade later.

Dave

Edited By SillyOldDuffer on 01/06/2020 11:05:31

Ron Laden.