Unable to find an enclosed twin with any form or Rotary Valve by Westbury.

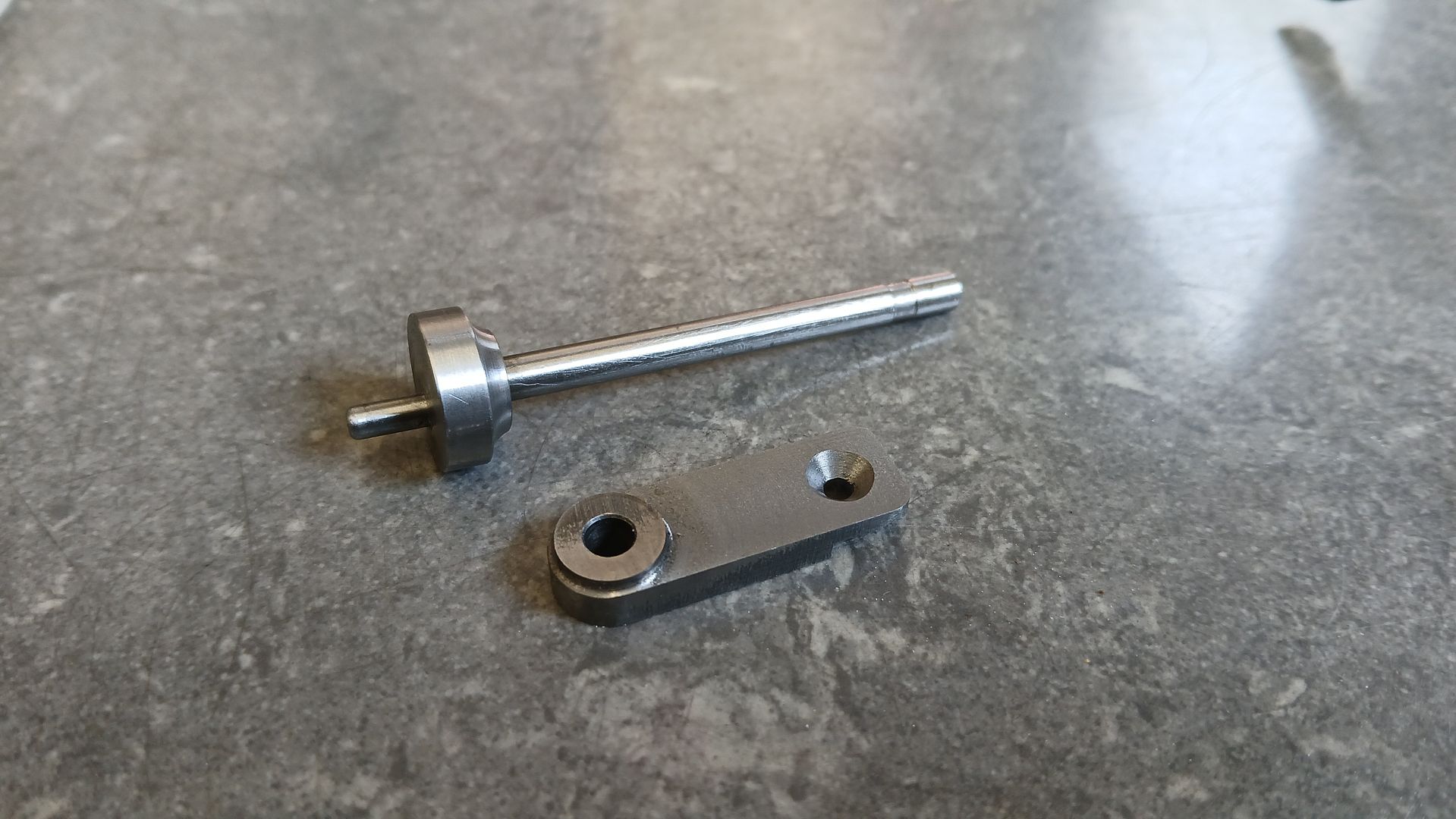

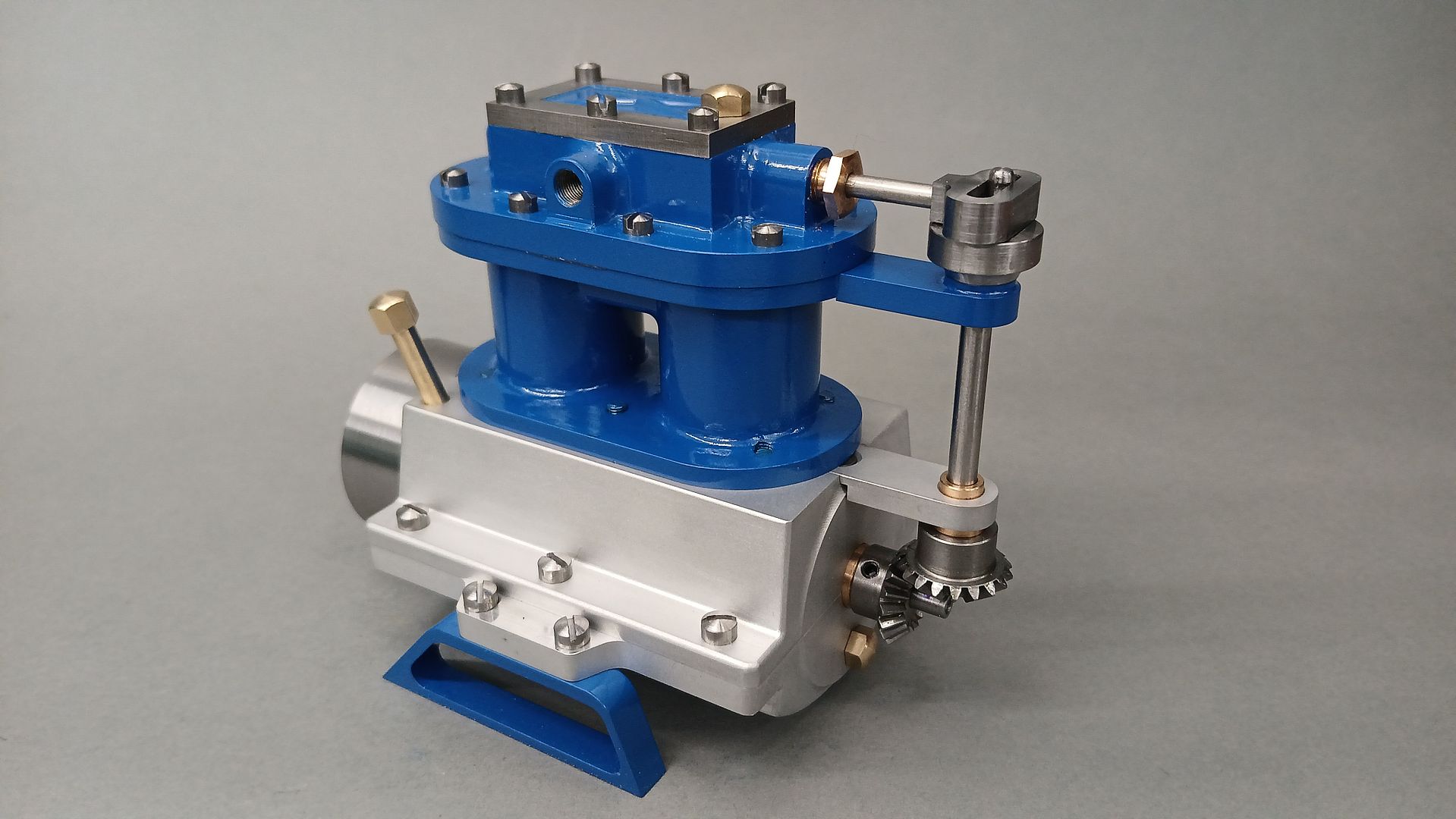

I did not take any photos of the valve, its nut or rod as they are nothing special and just like you find on any slide valve steam engine. The Scotch yoke that drives the valve rod was machined onto the end of some round bar, sawn off and then milled down to the final 5mm thickness before drilling and tapping for the valve rod.

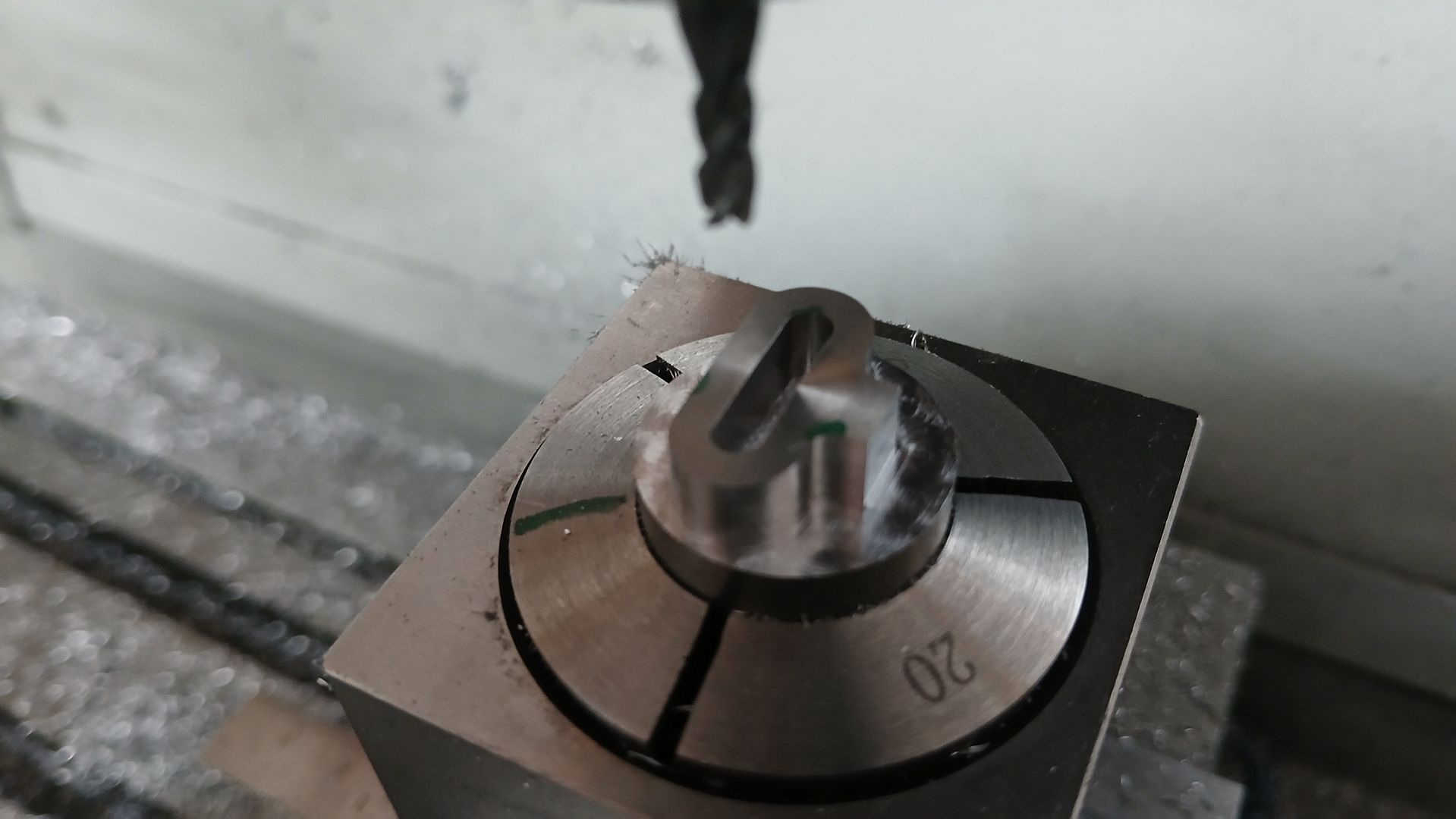

As the eccentric drive pin has quite a short throw and would clash with the vertical shaft I chose to turn the pin and disc as one piece and then Loctite the 4mm silver steel shaft into a shallow hole rather than inserting one then trying to drill and ream an overlapping hole.

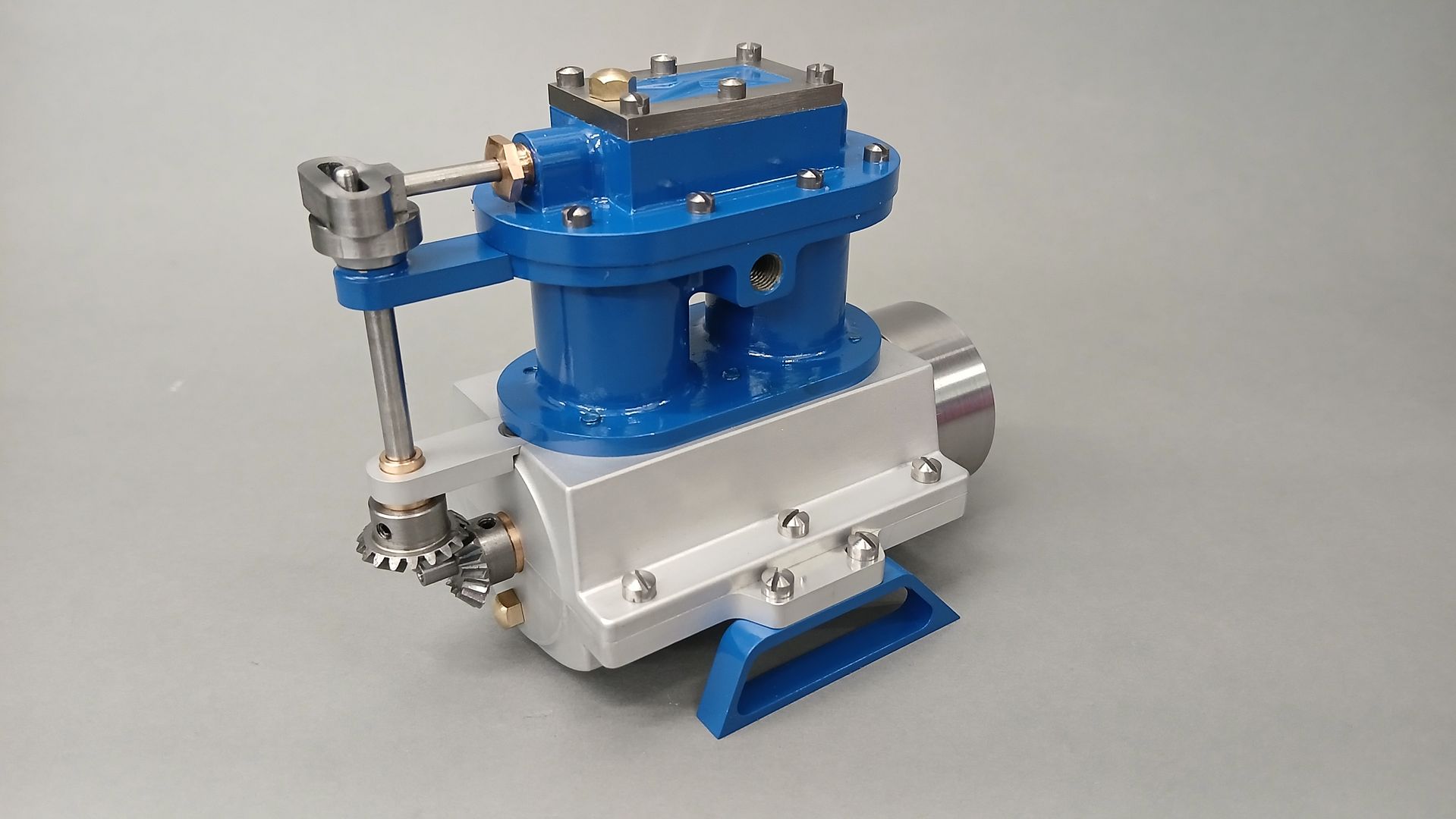

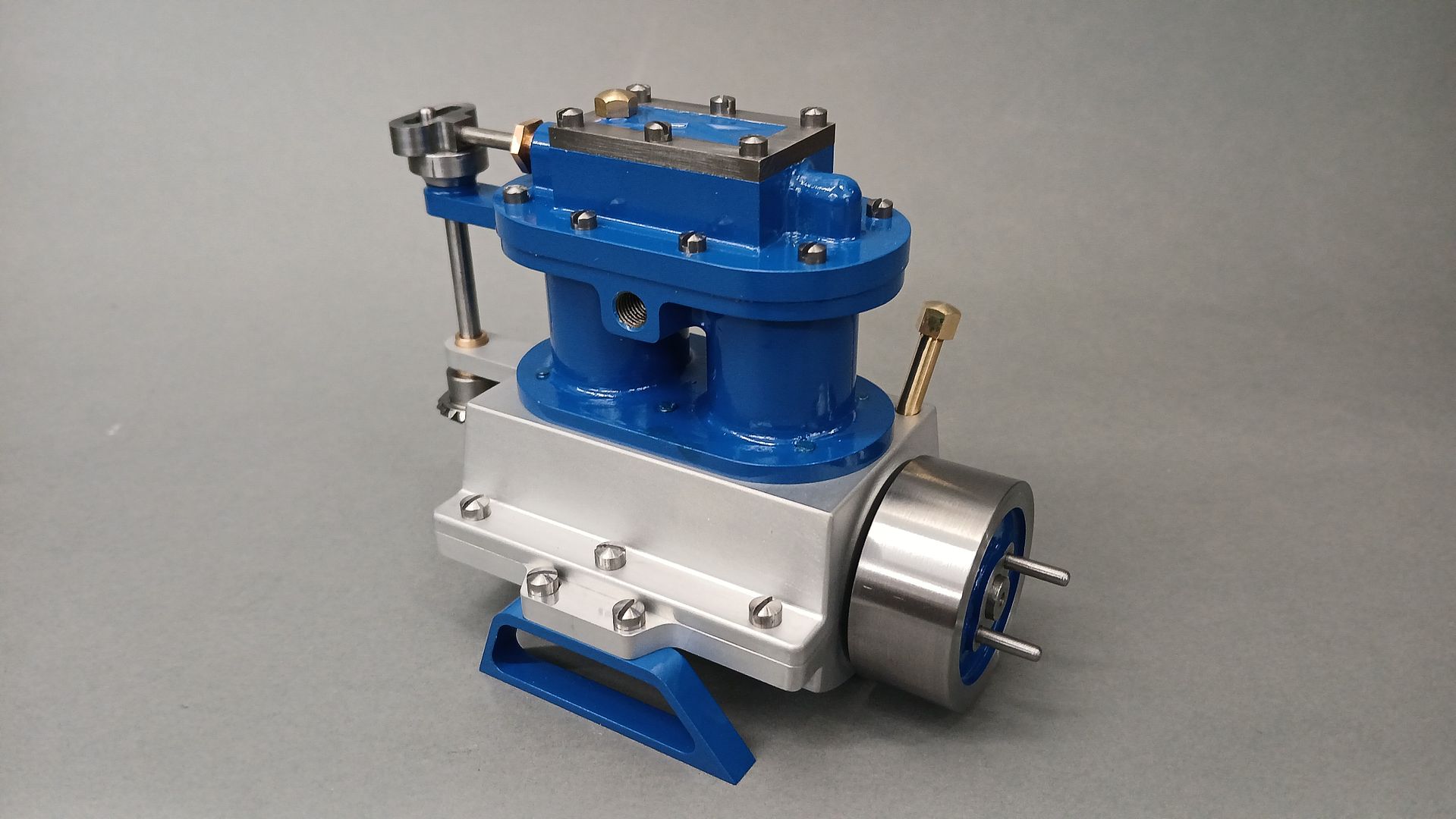

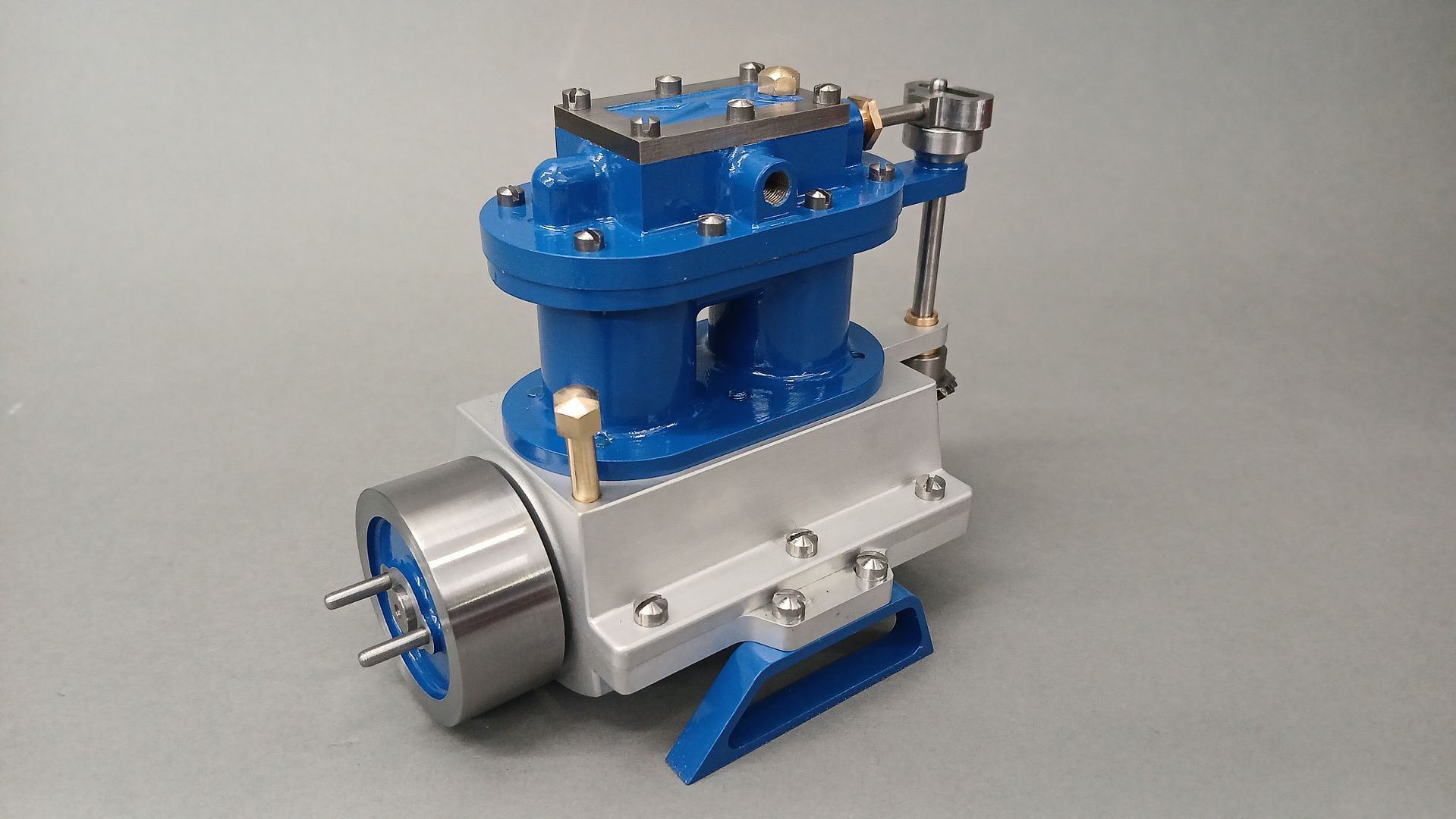

The photos of original engines seem to all show them assembled with screws so I machined up a batch of Filister nead ones in M3 and M2.5 which completed all the machining save for a couple of plugs for the drain and valve chest oil hole and a capped tube to fill the crankcase with oil. The Aluminium crankcase halves were bead blasted and the “cast” surfaces of the iron parts given a coat of paint.

I only assembled the engine with a couple of drops of oil on the moving parts rather than filling the sump with oil so did not have the splash lubrication for test running. Also with no form of lubricator on the inlet I did not want to push my luck too far. But with a larger diameter inlet tube and 45psi on the regulator I was happy to stop the test at 3000rpm and expect the engine could go faster as I did not have the flow regulator fully open. Sorry the Tacho video did not come out but you should get an idea by the noise at the end of the video.

Howard Lewis.