So for Christmas I made a Candlestick out of steel and brass. Mainly to prove to SWMBO that my hobby could actually produce recognisable things.

This quite confused her as it was reasonably good and recognisable, but soon enough she found the flaw. It drips wax. It's a fire risk. It needs a wax catcher. And it was duly put to one side.

Never one to be daunted, I've eventually got round to making my wax catcher.

the idea was a round plate of brass flat to the base of the tulip thing that has the candle in and then curving up.

In metalwork in the Dark Ages we were told about spinning (and may have seen a demo, though that's beyond my memory).

I've put a threaded hole in an MT3 blank, made a drawbar for it and added a 50mm extension (which is the size of the tulip things outside diameter).

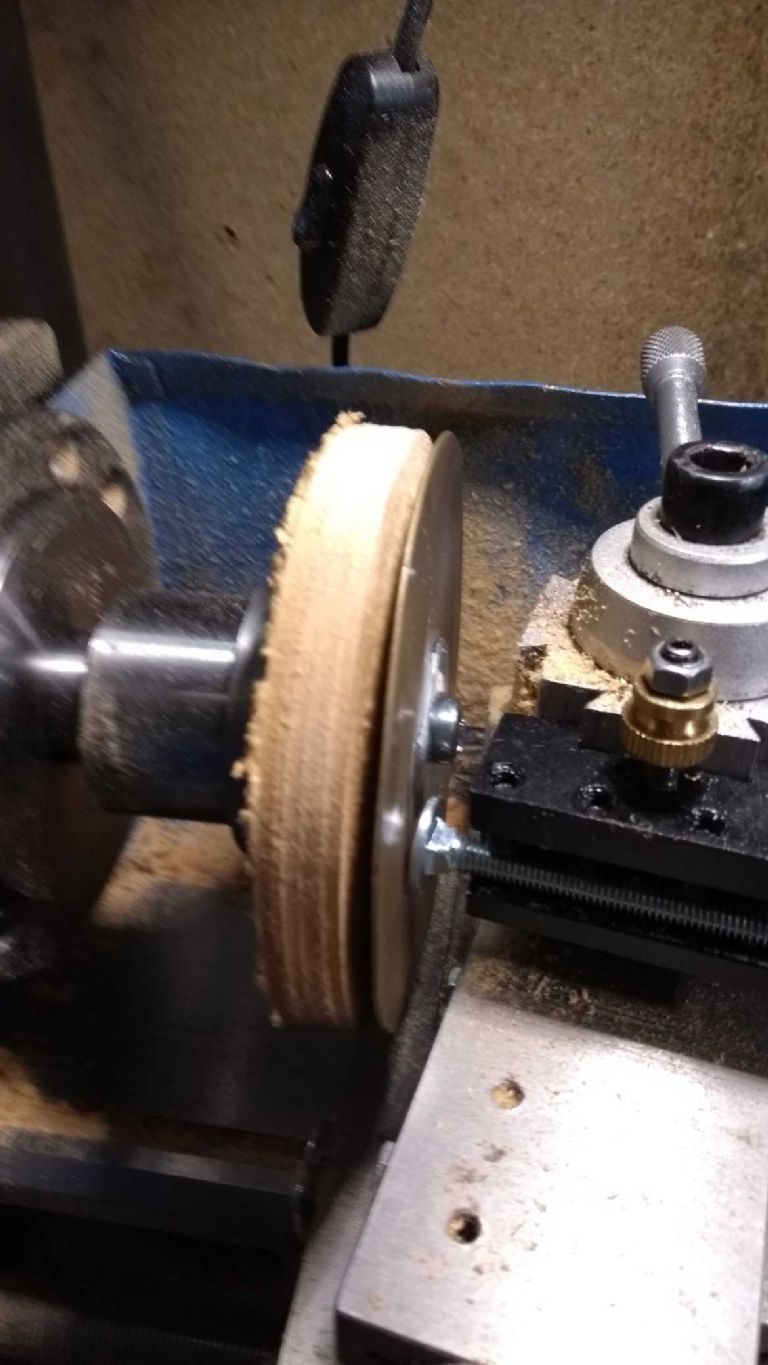

I mounted the brass place more or less snipped to shape onto a piece of ply and bolted it to the MT3 thing (is that an arbour of sorts?).

That worked really rather well (always a bad sign).

Next took the wood back off, bolted the plate back on, turn the speed up to high and tried to reshape it.

Somehow, it's managed to have almost no effect except to buckle the plate very slightly out of flat (1mm or so).

I can get a curve out of the brass with my pusher as it spins (first a spanner end and then a hammer shaft to get a bit of leverage), but it always springs back (apart from the buckle I've somehow put in). The curve looks to be around 10 – 15 mm at the edge so it's a fair amount.

The plate is about 3mm thick and 100mm diameter the inner diameter (the tulip ) is about 50mm.

Don't ask me what sort of brass it is. It's the sort sold at the Alexandra Palace show.

Any assistance would be welcome (including the less than ideal, 'You can't do that with brass you daft brick' .

.

Thanks

Iain

Edited By Iain Downs on 22/07/2017 18:40:35

Iain Downs.

.

.