Posted by Greensands on 06/09/2020 20:26:19

Posted by Greensands on 06/09/2020 20:26:19:

A lot of very useful help and advice given here – Thanks for that. It would appear that my best options would be to use either the Lumiweld 5 rod + Wire Brush Kit or to try Alsol, the flux cored solder sold by Cup Alloys. I should have said that the cosmetic treatment involves filling a line gap from the inside of a concave shell casting typically 0.020" thick x 1" long which after soldering would be filed down to maintain the external profile.

Good luck if you do go the Lumiweld, Technoweld, GAZ or any other route that requires a flame to heat the job so the rod runs, with such a small thickness of parent metal take a lot of care or you are likely to end with a hole and a spoilt casting.

Advise you have a few dummy runs with some scrap of the same material to be repaired.

Emgee

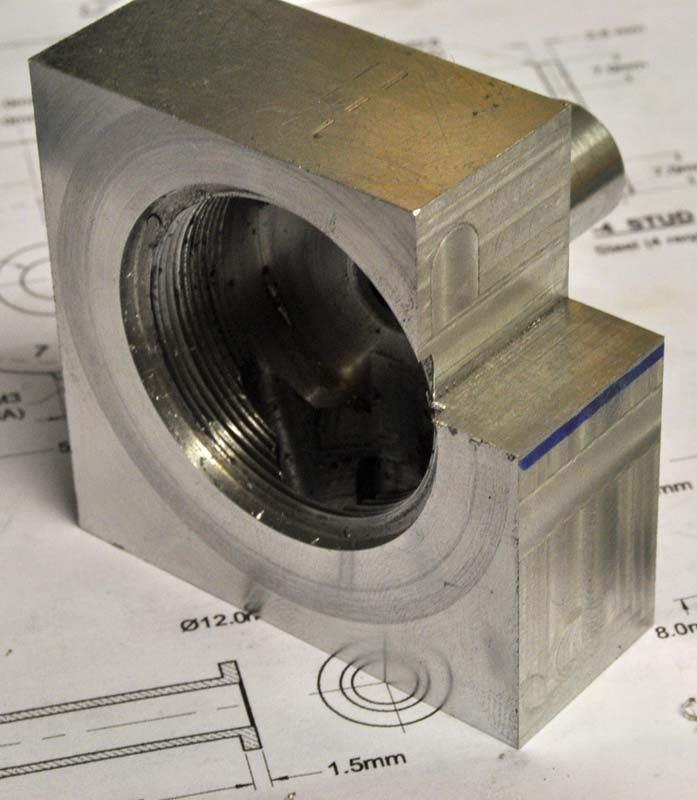

picture of another make of rod + flux

Another product from UK Brand: Sif Product Model: RO553212

Edited By Emgee on 06/09/2020 21:00:22

Edited By Emgee on 06/09/2020 21:09:07

old mart.

I'll remember that.

I'll remember that.