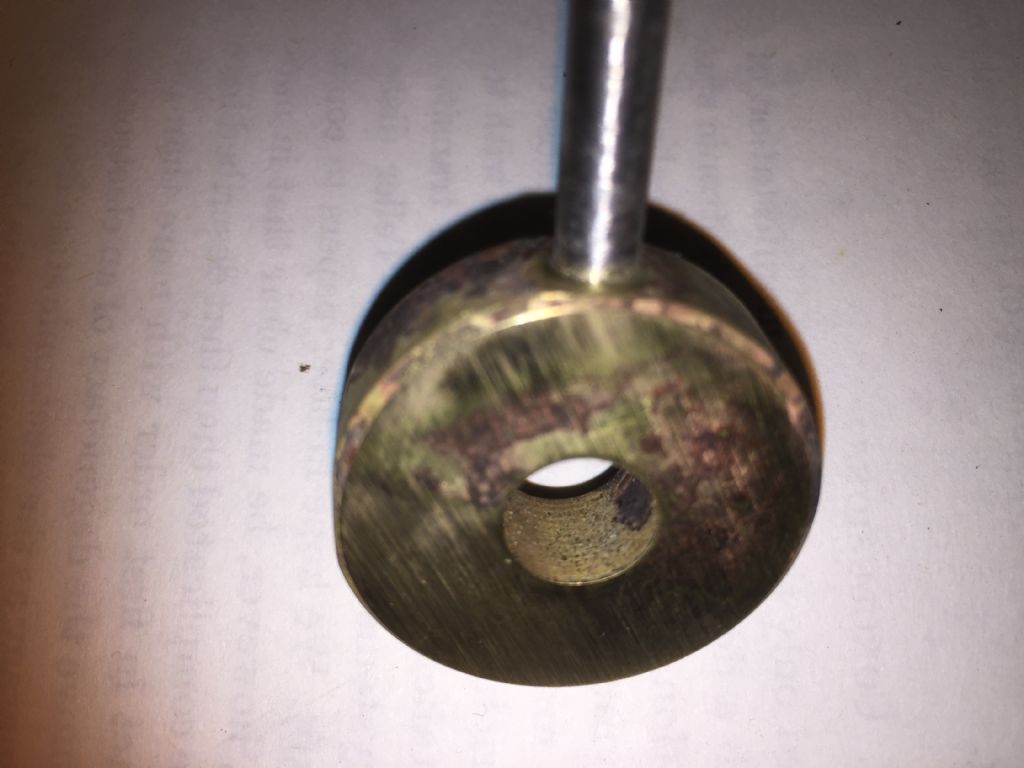

Other things having intervened as they inevitably do, I've only just got round to trying the paillon method Michael suggested. This is a poor photo (I rue the day I 'upgraded' to an iPhone!) of a test using scrap pieces:

Despite the poor focus you may be able to see that the solder migrated from the bottom of the blind hole and has wetted the stainless – there's actually a reasonable fillet as well. So thumbs up for this technique!

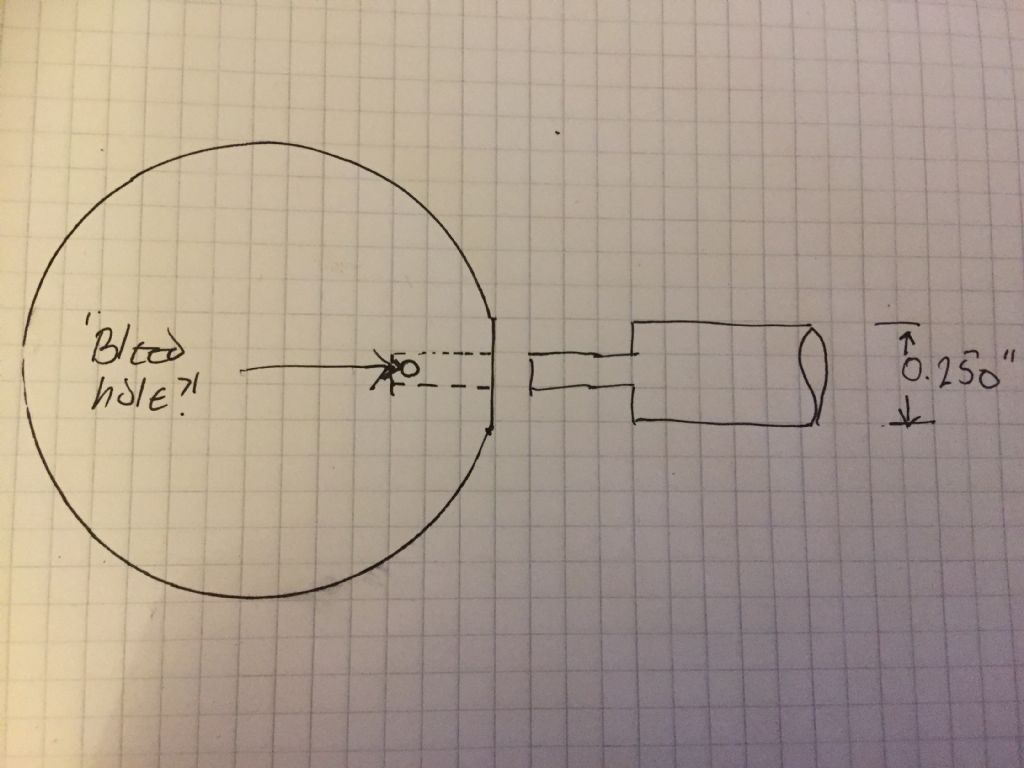

This is nominal 5mm stainless in a hole drilled with a 5mm bit. . As best as I could measure the stainless was 4.974 mm and the hole 5.015mm. Plus or minus a tad obviously*, but rather less than the minimum clearance recommended in the CuP guidelines. Anyhow it works!

I heated very gently at first to dry the T5 flux paste, no problems with steam forcing the thing apart.

Robin.

*In a previous life I had to mark lab reports from undergraduate students. One of the tasks we set was was to estimate the distance between the hydrogen atoms in water molecule by a nuclear magnetic resonance technique. One pair came out with something in the region of five metres, quoted to 12 significant figures. It's what the calculator said, numbers on an LCD display, so it must be right….

R.

Edited By Robin Graham on 20/03/2019 23:26:04

Edited By Robin Graham on 20/03/2019 23:36:26

JA.

JA.