Oh go on then, I'll have a go.

1 Are they like stepper motors and need a separate controller?

Yes, almost always. There are some with the controller built into a housing on the motor, but it's pretty rare.

Just to be clearer, the box of tricks which connects directly to the servo motor is called the 'servo drive/driver' or 'servo controller'. But just like with a stepper motor driver, you typically need e.g. a computer or separate motion controller to tell the servo driver what to do, usually by sending it step/direction signals.

2 Can they do single steps?

Yes, if the controller is set up to use 'step and direction' inputs. Typically there are loads of other control modes as well, e.g. a simple voltage input to control speed.

3 Can they be set to run at a certain speed without external control?

Generally, yes – you can usually program the driver box to do that.

4 Do they all have positional encoders built in?

As far as I know, yes (i.e. there is an encoder built in, on the motor shaft). The resolution of the encoder varies of course, and there are many different types. They are only rarely interchangeable between makers or even between model ranges by the same maker, so it's best to buy motor and driver box as a set (also making sure you get all of the necessary cables).

5 Are they all powered by DC power supplies?

Not at all – you can find some DC powered ones but generally servo systems relevant for CNC are powered by AC i.e. mains, connected into the driver box. Bigger ones need three phase in. Some also need a separate 24V input for their control circuits. Typically you'd install drivers etc in a control cabinet with appropriate circuit protectors, contactors, PSUs etc. The manual for the servo driver will specify what's needed.

Note that when talking servo motors, AC vs DC usually refers to the TYPE of motor, not the electrical input to the driver box. AC typically means "brushless three phase" and DC usually (but not always, confusingly) means "has brushes". The brushless AC type has pretty much taken over now.

6 Is there a type that is best for a particular type of job?

Bit of an open question but for hobby CNC axis drives most people seem to use AC servo systems at about 200-400W nominal power. There are many online calculators to help you size servos correctly, and also bear in mind that most will put out up to about three times their nominal rated torque for short periods.

7 Can single step motors be run at higher speed (eg 1200 rpm)?

I'm not sure what you mean by a 'single step motor' but in general servos can usually go to a few thousand RPM. If you are using a 'step and direction' input to drive the servo, and its encoder gives many steps per rev, you will need something capable of putting out the steps very fast to get high RPM. Most servo drivers have an option for 'electronic gearing' which effectively lets you set it up as if the encoder was lower resolution than it actually is, so a slow stream of steps (from e.g. a parallel port) can still rotate it at decent RPM.

8 As I know nothing, can you think of something basic that I haven't asked about ? If you can, I'm certainly ignorant of it and would like to change that situation.

Well, the main advantages over steppers are:

- Higher torque at higher speeds

- Never lose steps (because encoder)

- Steps can be smaller (because encoder typically much higher res than stepper step size)

- Quieter/smoother

Main disavantages

- MUCH more expensive

- Can be harder to set up (modern ones less so)

For most purposes steppers are fine. If you want to drive something a bit bigger or faster, then servos are probably the way to go.

The price is falling for servos, though – see e.g. here for some from a reputable China seller… brand name ones tend to be a lot more. There are also UK suppliers who can advise and offer backup e.g. Zapp.

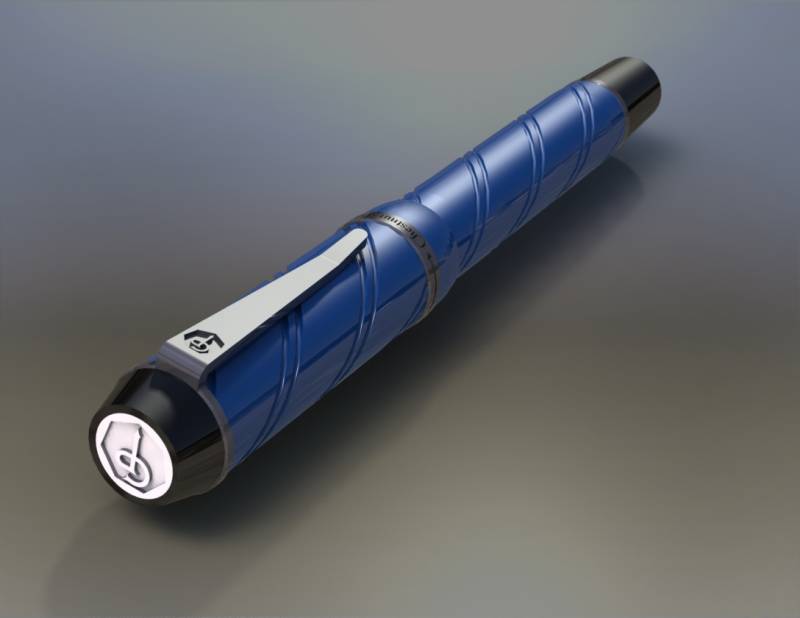

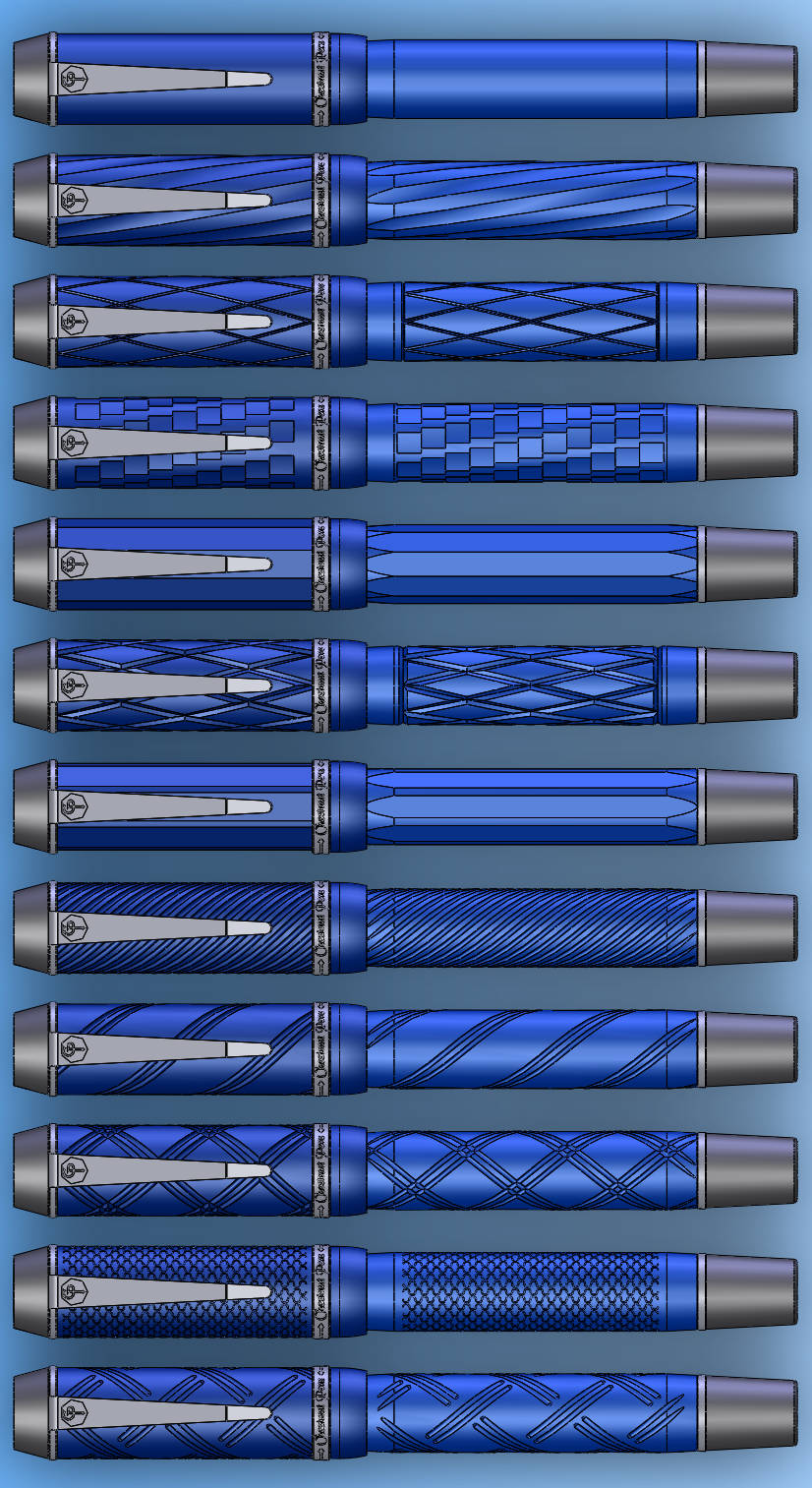

I intend to convert a Clarke 430 to CNC, and want to do engraving on the outside of the cylindrical objects (fountain pens) as well as the usual cnc lathe stuff. What I don't know is whether I am going to be able to use a single servo motor on the spindle for this, or whether I'll need to keep the 1 phase motor for the turning, and then detach that and use a separate stepper motor on the spindle when I wish to do the engraving. This is the sort of thing I want to engrave on the outside:

Yes, you can drive the spindle with a servo motor no problem – it's a 'deluxe' solution used on many CNC lathes and will also be handy for threading. You'll want to connect it to the spindle with a toothed belt, though, so there's no slip, and use a fairly hefty servo motor.

The alternative you suggest of just using a stepper to position the spindle when it's needed as a rotary axis (for engraving) would end up a lot cheaper, though, and I can't see any reason it wouldn't work fine.

Edited By Bikepete on 06/06/2017 17:23:44

Mike Poole.

Mike Poole.

and intend to use for the CNC lathe, & move the router there when done. But I doubt that'll be this year – we've just bought another 26 sheets of 8x4ft plasterboard which may be enough it and I am very slow at plasterboarding. This building was roofless when we got it, but now has a slate pitch roof with 2" of insulation underneath & will have a dpc fitted by the time the plasterboard goes up. One of the delays has been caused by the foundation failure of the building next to it, and the time we spent replacing it using all the same bricks. So, the kids have a nice 11ft x 13ft play-room to ignore…

and intend to use for the CNC lathe, & move the router there when done. But I doubt that'll be this year – we've just bought another 26 sheets of 8x4ft plasterboard which may be enough it and I am very slow at plasterboarding. This building was roofless when we got it, but now has a slate pitch roof with 2" of insulation underneath & will have a dpc fitted by the time the plasterboard goes up. One of the delays has been caused by the foundation failure of the building next to it, and the time we spent replacing it using all the same bricks. So, the kids have a nice 11ft x 13ft play-room to ignore…