Beaver/Baldings closed down around about 30 years ago.

I am almost certain that I got a pair of spare table gibs when I first had my VBRP Mk2. They are complex double tapered, odd looking things. A thread rod emerges from one end, and this locked with a pair of nuts either side of a fixed part, so they are positively held in both directions after adjustement. I also think they are a right and left handed pair.

I could try to take some dimensions from it if you want, and maybe photograph it. Best would be if sommeone could put it on CAD.

Later…

I have found them, they are a matching pair. Cross section is parallelogram with angles 35/55 degrees. The section is constant height, but tapered width.

They are 10 ins long (254mm)

At the fat end, the parallellogram is 0.6317 ins (16.045mm) by 0.7351 ins (18.671mm)

At the thin end it is 0.4911 ins (12.474mm) by 0.7351 ins (18.671mm)

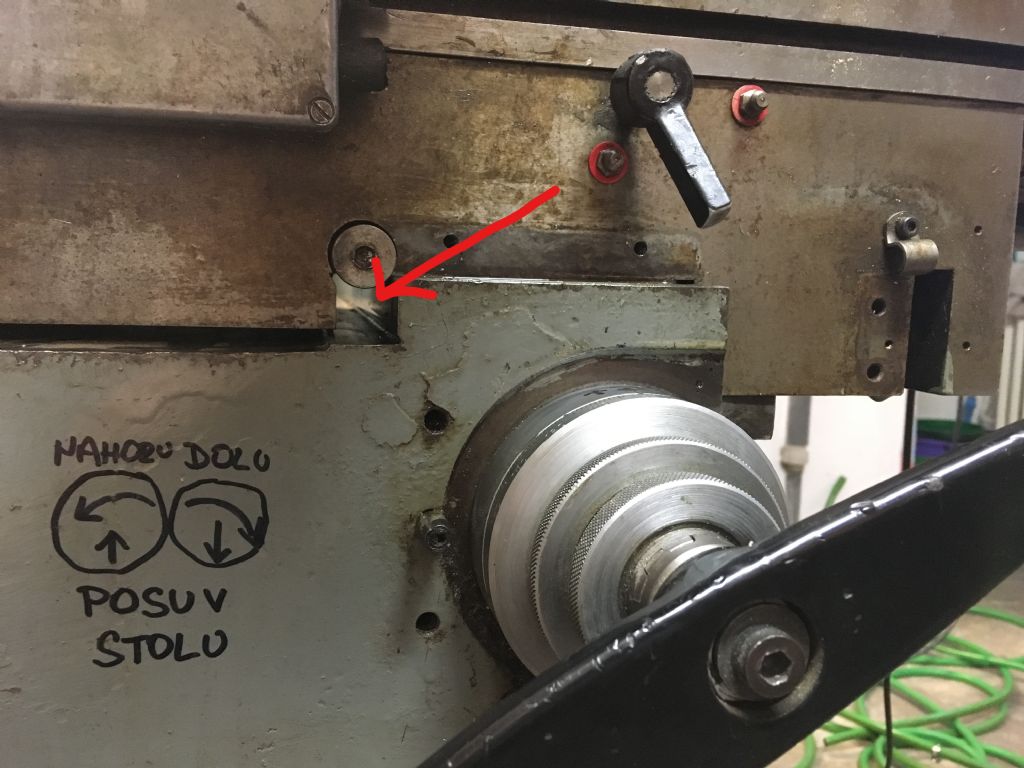

The fat end has a slot 7.4mm wide by 8.81mm deep, 8.34mm from the end. It is the slot that is used to lock the adjustment. The threaded stud I mentioned must be the stationary part. There is a blind hole about 6mm diameter 77.5mm in from the fat end in one face.

The part seems to be made of carbon steel and hardened after machining all over. One side looks to be ground then hand scraped flat. There is a witness mark on one face where the table locking screw has pinched on it.

I'll follow up with photographs when I get a chance.

Edited By Peter_H on 20/06/2018 16:34:49

Edited By Peter_H on 20/06/2018 17:13:30

Mark Guy.

*

*