Hi Rob,

I’m hoping that you have some grasp of 3 phase…..

So first off you need to take a look at the face plates of the motors on the machines….

Fingers crossed that they are the dual voltage variety, 415v /220v which means that with a bit of jiggery pokery you can make them all 220v.

Even if they are not, If your motor is internally connected for single circuit delta at 400vac, it could be internally reconnected to a 2 circuit delta for 200vac but this means you need to take it to someone who knows what they are doing and will cost…which is what I did.

Keeping the voltage the same as the mains voltage (220v) greatly reduces the cost of the inverter as it doesn’t have to induce 415v as well as create the third phase.

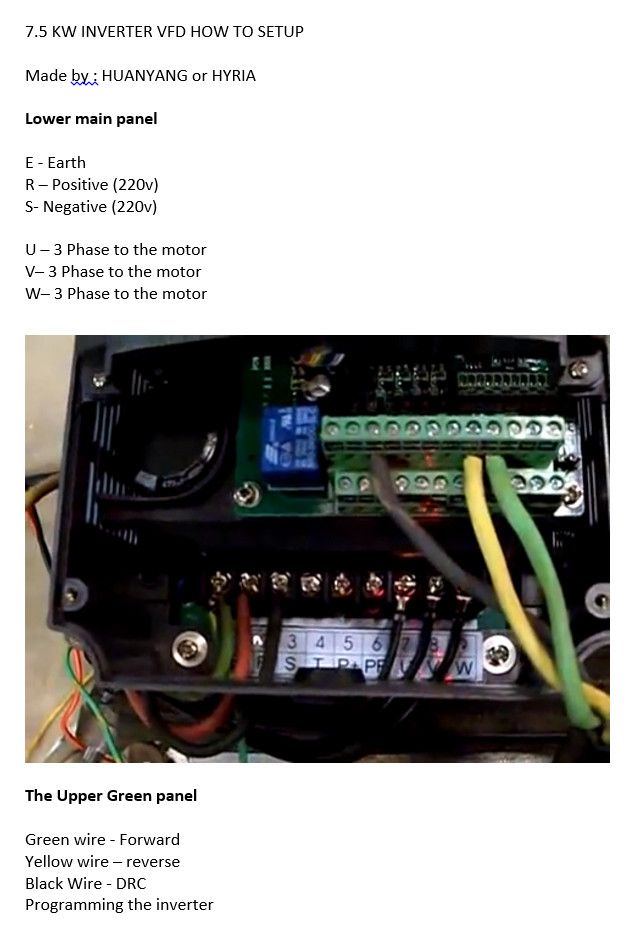

The main motor on my Beaver MKII is 5KW 220v 3 phase so I went for a Hyria 220v 7KW inverter (single phase in, 3 phase out but remaining at 220v) which gives a bit of overhead when the main motor starts, due to the initial draw of current to get the lump started and also powers the feed motors which are a lot smaller.

In fact I have a bit of rats nest that feeds all my machines as I only ever use one at a time being me, myself and I.

You might have an issue with the magnetic contactors for the power loss disconnection but so far, touch wood, I have not seen this happen.

The transwave I find are overpriced and are sourced from China so why not go to the source and cut out the middle man. This is a personal opinion and I would dutifully buy if it was made in the UK the same reason I bought a Beaver rather than a bridge port. You are taking a risk but PayPal protects you and so does eBay. If it doesn’t work, never arrives, or there are issues communicating with vendor then you get your money back. You can’t get better than that.

Dan

Mark Guy.