Ian; some data points for you, reinforces some of what is said above:

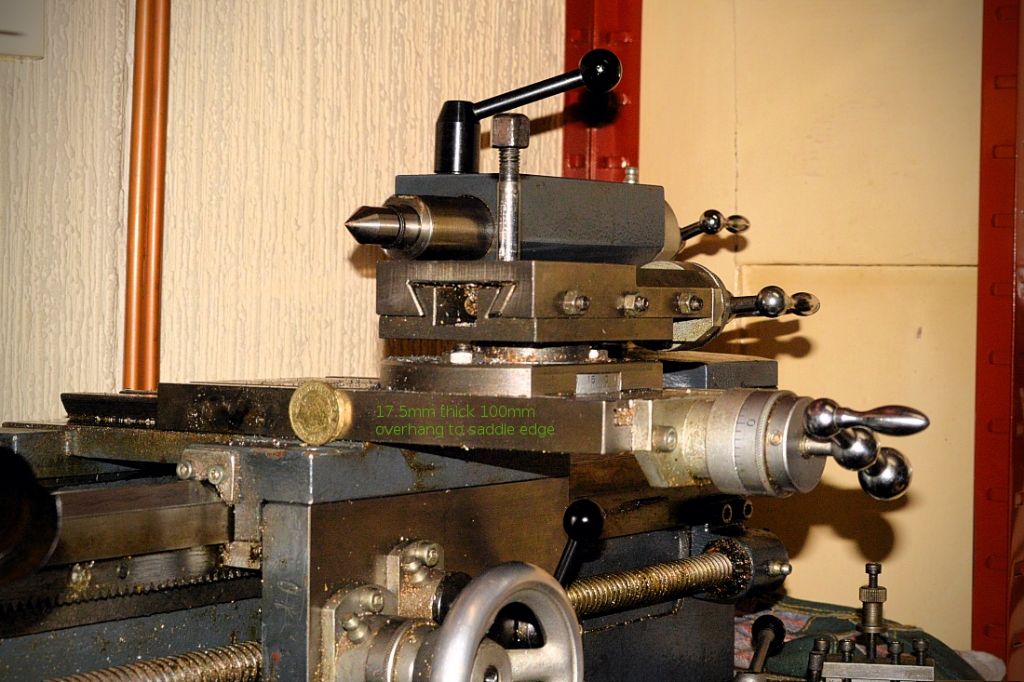

On my Emco Compact-8 lathe:

0) I turn smaller parts on this lathe, have a larger lathe for large parts;

1) I now have an American "A2Z" aluminium tool holder; rigidity is certainly less than the old steel one I had;

2) I wanted a small tool holder for small tools, one that held tools on two sides of the post (boring, facing), so having a small toolpost was less wangling of the cross slide feed handle;

3) I made a holder for a 0-25mm dial indicator, consisting of an aluminium block, a strong magnet from an old disk drive, it "clamps" to the side of the ways and can be moved about as required.

4) I still have the compound rest, but rarely twiddle with the dial. With the dial indicator, and the large carriage handwheel, I can actually get quite precise movement.

5) I have the parts (but not the time yet) to fit a handwheel to the RHS of the feed screw, as you see on many Myfords.

I would be hesitant to recommend the A2Z toolpost holder for a larger lathe like mine; but it is designed for the Sherline and Unimat lathes, so (if, like me) you use it within its intended design range, it is great.

Whatever you do, you'll find you need more and more tool holders…

John.

andrew lyner.

I'm being polite.

I'm being polite.