Thanks guys, I've solved the problem at least for now and you've made 1 man very happy

It was a problem with the brushes as you suggested, one was worn far more than the other and the contact wire that run through the springs were in a poor twisted shape.

I've straighted out the contacts, and given things a bit of a clean and it works fine now. I'll order a new set of brushes / springs etc from Chester on Monday but the repair I've done for now should tide me over for a few days.

What initially I thought looked like a disaster actually turned out well, it gave me chance to familiarise myself a bit more with the machine and generally check a few things seem to be running ok.

Mike, you are right it will be under guarantee but I thought I'd ask here first in case it was a job I could fix myself as was the case. When I speak will Chester I'll see if they send the spares free, if not I'm not going to haggle over a few quid, I'm just happy it works ok.

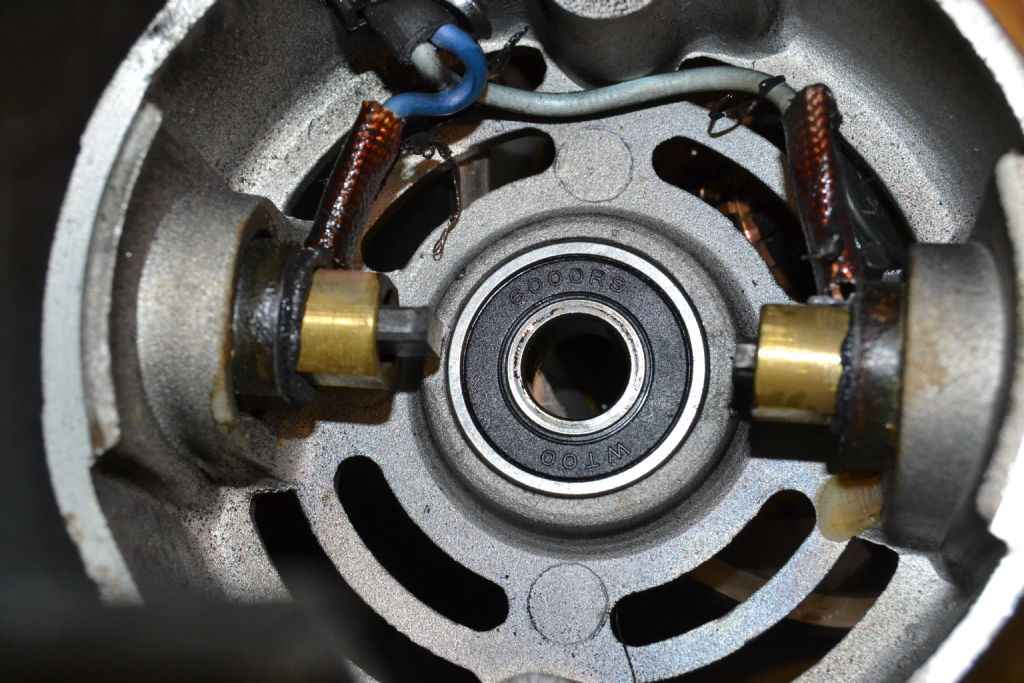

Here's the state of the brushes :-

Thanks

Peter.

Gas_mantle..