Hello

I hardly dare re-kindle this old thread….

"Small saw. Proxxon or something else"

https://www.model-engineer.co.uk/forums/postings.asp?th=172361&p=1

**LINK**

…However I find that I do keep needing to cut long thin strips of material. It's usually either wood/plastic (e.g. ABS/PS/Nylon), or stainless or mild steel.

My requirements have evolved since that thread so I shall this new one.

My cutting requirements are:

1. Material thickness:

My steel is generally between 0.9mm and 1.4mm.

2. Lengths:

My lengths might be say 10 to 20cm,

with a width of maybe 2 to 5mm.

3. Materials

Steel is obviously the hardest of the things that I need to cut. So a small machine that could even cut just steel would be a revolution for me. But would it be too much to hope for one machine that could cut both materials? (Like my fine-toothed hacksaw can!)

BACKGROUND/PROBLEMS

To be honest, my hacksawing skills aren't very accurate. It's particularly difficult, particularly after dark when there is less daylight to help me see what I am doing. Seeing marked lines on steel (even when using Dykem Steel Blue) is quite difficult…

So I find that I keep having to hacksaw somewhat over-sized and then hand-file or grind down and remove quite a lot of material to get them down to the precise required sizes.

==> So I find myself fantasizing about a precision/micro table saw that can also cut steel! Or possibly some rig to enable me to do hacksawing with great precision?

From memory (and without re-reading the entire previous discussion):

a) Small table saws (e.g. Proxxon) ==> just aren't designed for steel

b) the Proxxon band saw definitely wasn't

c) Larger, more powerful table saw just aren't designed for cutting small precision parts.

d) A nobody seems to make small grinding disk wheel (e.g. 1mm thick) embedded into a cutting table. [And no, I don't really have time to mess about making one!]

e) My strips are too long to readily fit onto my MF70 milling machine.

f) I don't think a guillotine will work because the leave one side of the cut steel sheet curved.

[ NOTE: As before, I do not have a permanent works space. Everything needs to be cleared away at the end of each day. So tools need to be fairly light and compact. ]

MY POSSIBLE SUGGESTIONS:

What about cutting using micro-sized angle grinder.

…And then finding some way to line up next to a ruler/straight edge?

[But how exactly? Have any of you tried this?]

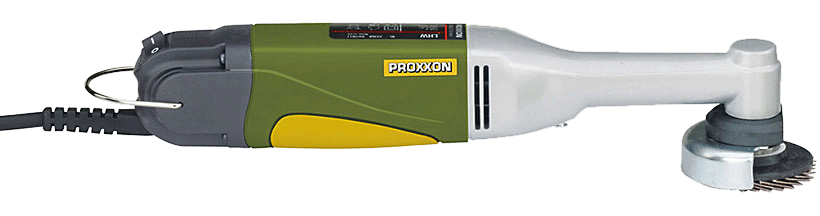

A. "PROXXON LHW LONG NECK ANGLE GRINDER"

https://www.axminstertools.com/proxxon-lhw-long-neck-angle-grinder-702027

– with cutting disk fitted

or

or

– "For steel, non-ferrous metals, glass, ceramics, wood and plastic"

– 50mm diameter discs

– 100W DC motor.

B. Or possibly a DREMEL would be better (??)

e.g. "DSM20-1/5 710W Compact Saw 230V"

**LINK**

https://www.cromwell.co.uk/shop/power-tools/compact-saws/dsm20-1-5-710w-compact-saw-230v/p/DRE2674120F

– Blade diam: 77mm

– No load speed: 17000rpm

– Power: 710W (?)

– Weight 1.7Kg

– Dust extraction port for clean working environment (vac cleaner attachment)

– "1 x straight edge guide"

I was thinking that something that cuts with a very thin disk would create less dust, but the dust extraction port could mitigate that problem. Also claims to have "Excellent line of sight for accurate cutting"

Yes, seem like it will be damned noisy…

> Noise K Factor: 96 dB(A)

> Noise Sound Power: 108 dB(A)

> Noise Sound Pressure: 1.59 Pa

…whatever that really means, but I live with that. (With earplugs if necessary)

BUT it is quite big & heavy (at 1.7Kg), for more precise work.

Have any of you got one? Have you had much success in cutting straight lines with them by lining them up against straight edges ?

What do you think?

J

John Haine.

or

or