I was recently approached by a member of the Forum as regards had I done anything with the Tailstock dial on the Super 7. My initial answer was no, and that I did not foresee any prospect of doing such in the future. Not owning a Super 7 now would make the task harder.

George Thomas did an elegant solution to this problem some years back. A Tailstock Micrometer, chapter 14, page 160 of the first edition, "The Model Engineers Workshop Manual". While 0.300" per rev is fine for the Imperial user, although a little awkward as regards the tailstock barrel graduations, 1/8 th's. It was not so good when it came to a lathe with Metric units.

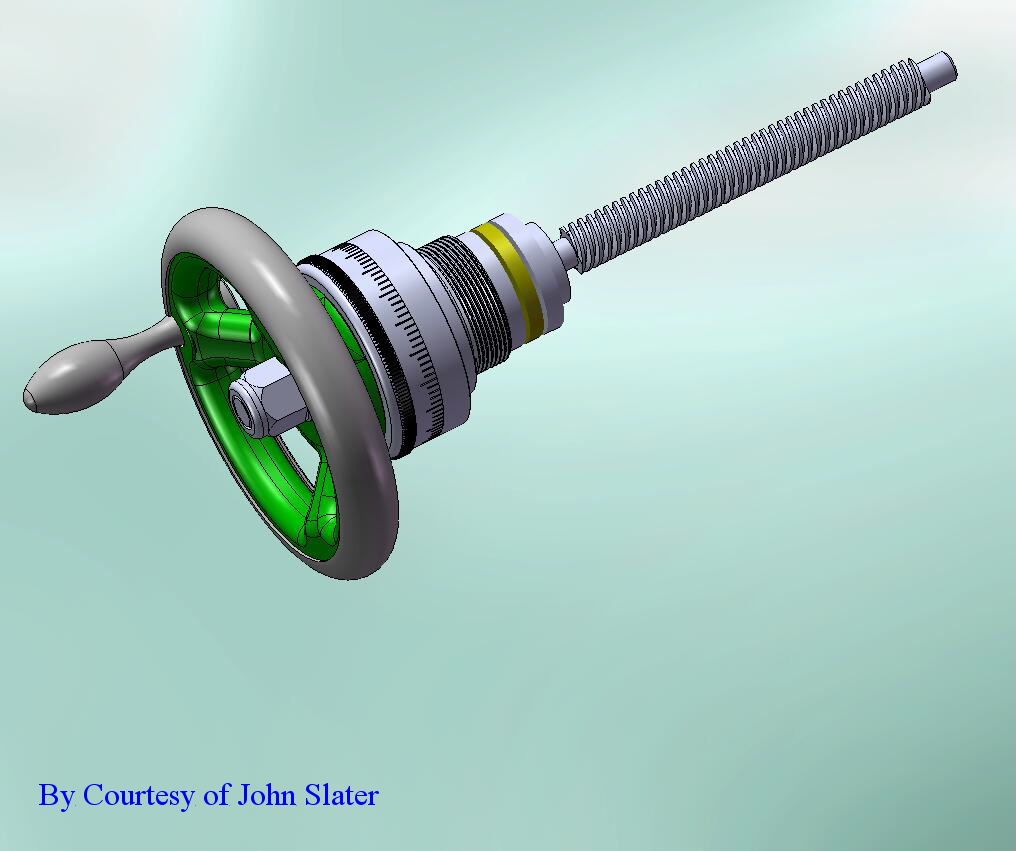

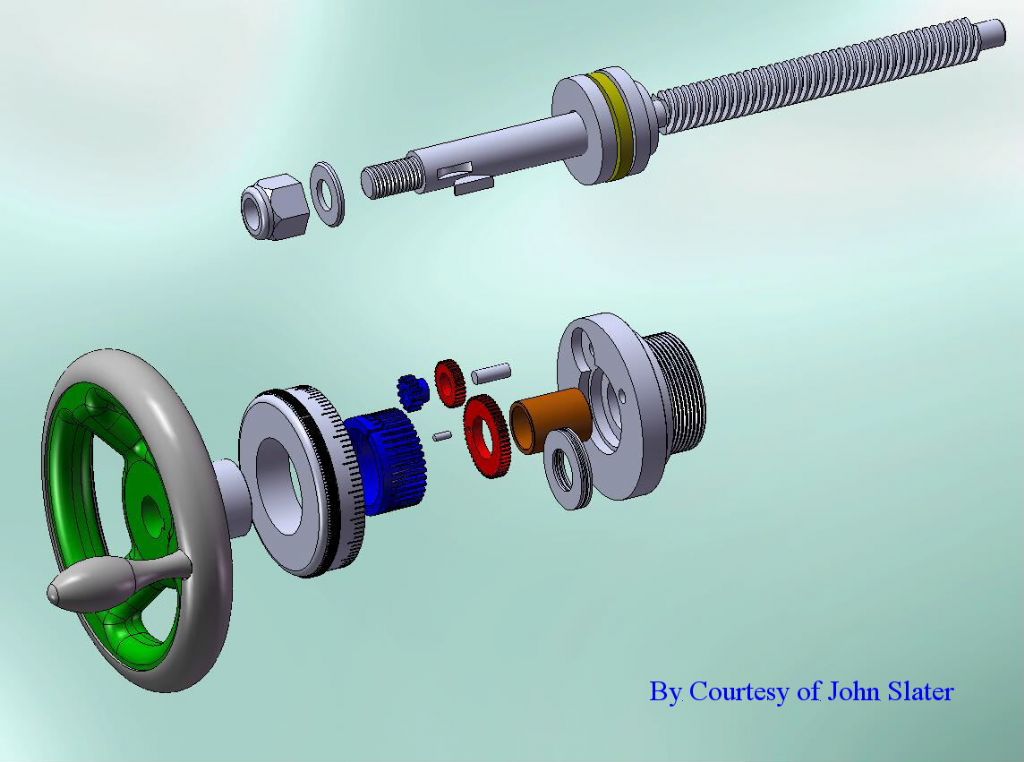

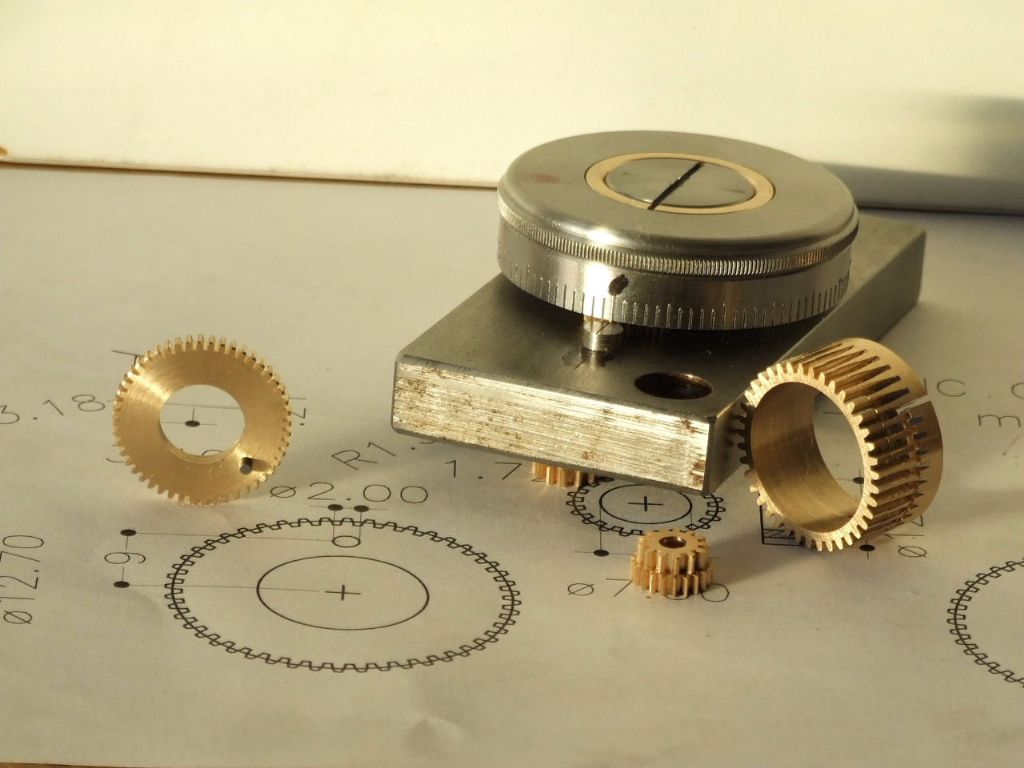

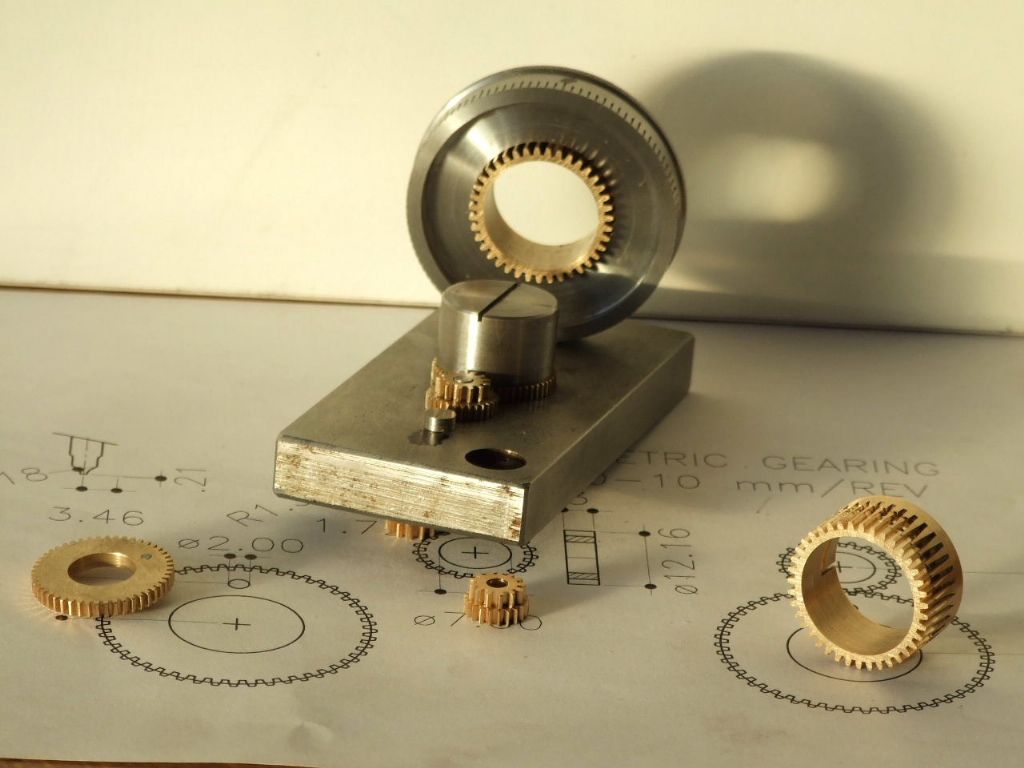

As is usual when a seed has been sown, an idea germinates. The initial problem with involving gearing in this dial is the need to keep the Dial small so as not to obstruct the handwheel in use. Normal reduction gearing would lead to an extra large dial.

The Eureka moment came when I was thinking about another problem. Speeding up the initial gear train then reducing it leads to a more compact Dial. Due to the reduction in bearing area on the face of the handwheel boss a needle roller thrust race has been added to make ejecting centres, arbors, etc easier. This is a worthwhile mod without the dial. An oilite bush has also been added to reduce the need to lubricate the bearing after assembly. An annual top-up should be more than adequate.

The metric dial is graduated 0-10 mm per revolution but has an inbuilt error of reading plus on the 10 mm dimension by 0.000127 mm. Over the entire barrel travel this would be nothing to worry about. The imperial version is graduated 0-0.500" and has no error, that is always assuming a theoretical pitch of 0.300" to start with.

Plans are however in hand to produce an article on these dials. Whether one of the ME suppliers takes up the manufacture of these dials then it is early days. For my part I want no part in this side of things.

Regards

Gray,

Steamer1915.

Steamer1915.