Posted by Dr_GMJN on 10/11/2020 14:57:44:

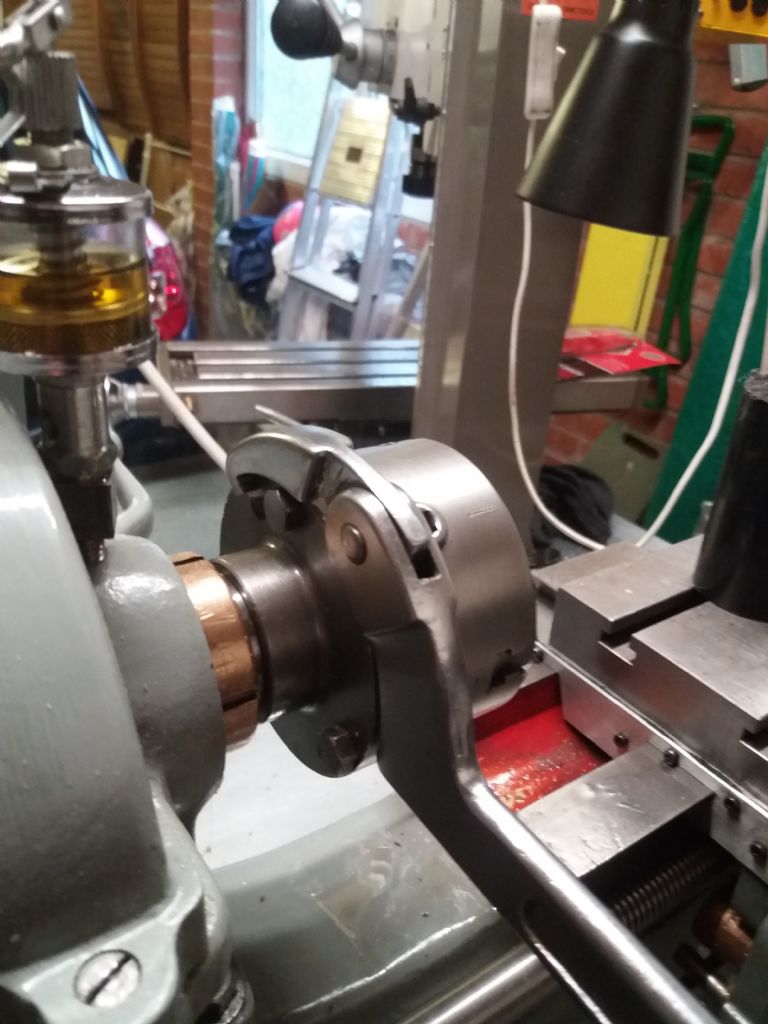

I remove the chucks by engaging back gear and putting a large adjustable spanner on the sides of one of the jaws. A bit of pressure releases them.

It's much better to hold a stub of large hex in the chuck then use the spanner – over time, constantly doing it your way will stress the jaws/guides eventually, however slight the torque required. Personally though, I always use the chuck key to provide leverage

Engaging back gear and or inserting a piece of hardwood between the mesh is about the only way of locking the spindle on an ML7 if I recall correctly. As said the S7 has that very convenient locking pin.

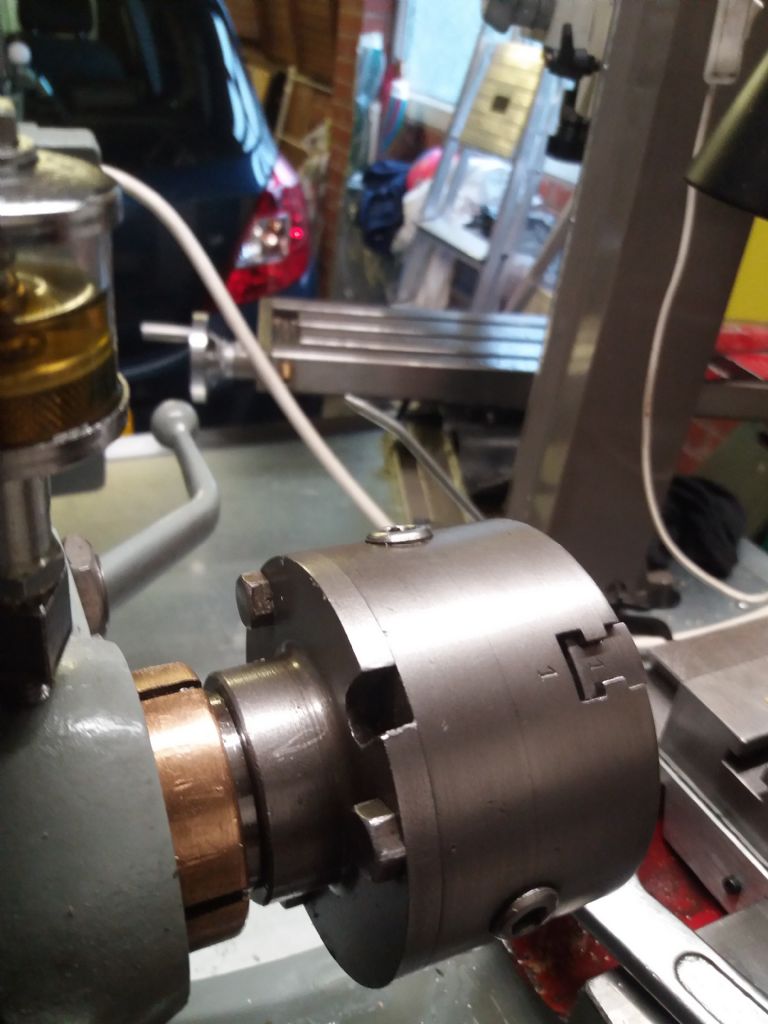

Something you may want to consider – a few years back I bought a TOS self centering 4 jaw chuck the aim being to use it primarly for square section (obviously) but without the need to clock an independent in. Prior to this my main chuck of use was a Myford/Pratt Burnerd precision scroll 3 jaw bought with an ML7 around 1974. I kept this chuck when selling the lathe on and still use it today however it now takes second place, virtually permanently set up with soft jaws, in favour of the TOS four jaw. Constantly in use now it's a brilliant chuck – accurate (enough) and will do all the other one will. Wouldn't be without it now for sure and would uy another in favour of a sc 3jaw without hesitation – just a shame you can't get one with a Myford internal thread.

With regards to the 5inch – bought one of those about four or five years ago. Concerned about the overhang/weight with a conventional backplate I took it apart and found that I could machine the backplate in reverse and fit it to give a mounting same as a Myford chuck. I use only when neccesary – it doesn't 'appear' to stress anything but it does 'look' like it is.

Regards – Ramon

Edited By Ramon Wilson on 10/11/2020 22:28:18

Bazyle.

Bazyle.