A little project that has been rumbling along since June. So far it's been living on another thread (LINK) while I have been practicing on some spare lathe parts but I think it's time to move it back onto my lathe thread.

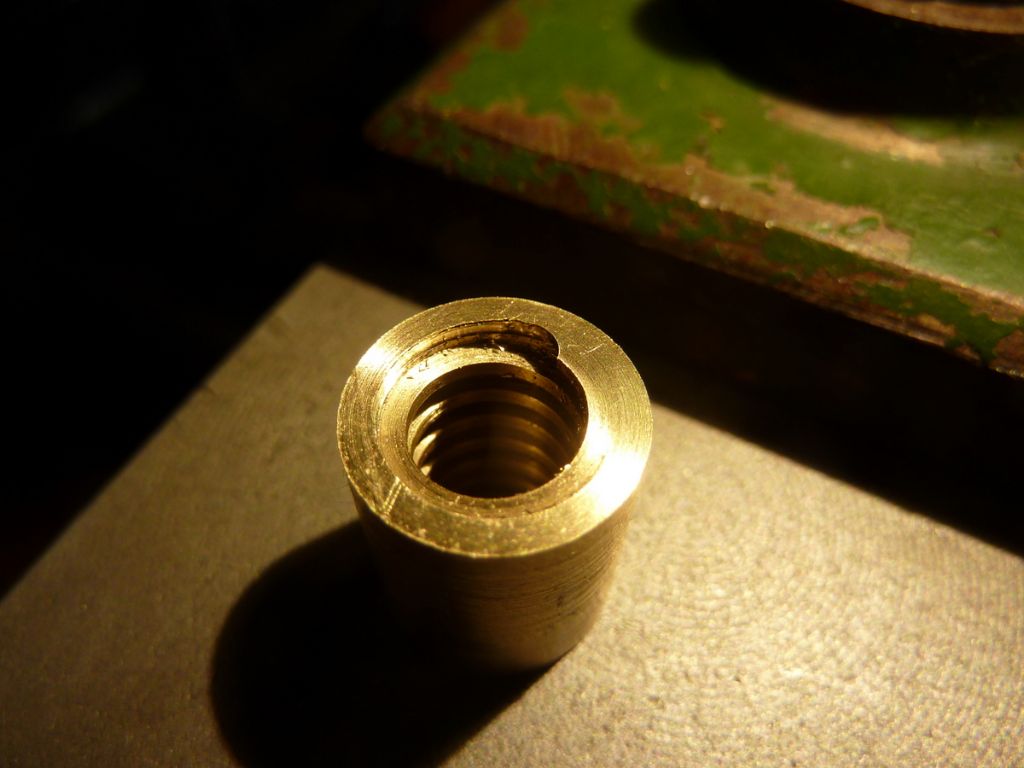

The basic problem is backlash in the cross slide – partly from wear in the feed screw and partly the nut. I've measured it at 45 thou at the worst. Today was the first time I'd looked really closely at the cross slide nut. The wear looks pretty scary so it's a good thing that I've been working on a fix.

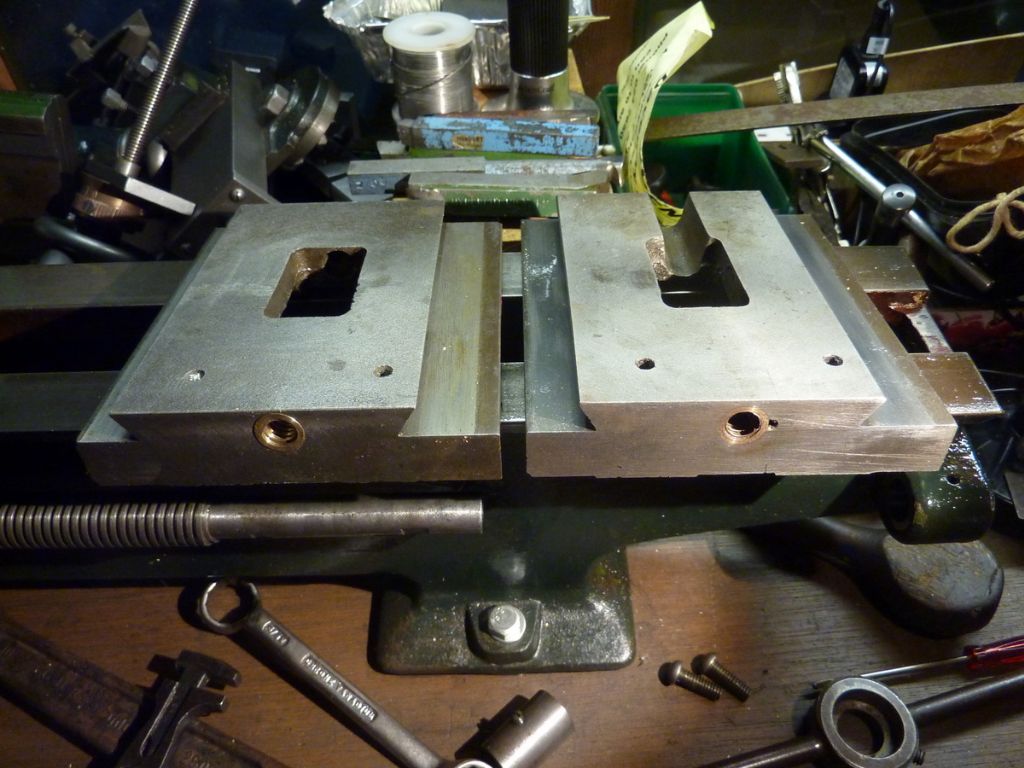

As a quick recap… the nut is a non ferrous part pressed into the saddle casting. This means it is replaceable but it's not easy… what with it having a 12 TPI square thread and a none too generous bore. My first attempt was to make the nut as a fully finished article. When I pressed it into the saddle it did not align well enough with the lengthy clearance bore in the casting – to the extent that the feed screw fouled the hole towards the rear of the saddle. I think the original thread was cut in situ so I've decided that I need to at least finish the thread using a tap in situ.

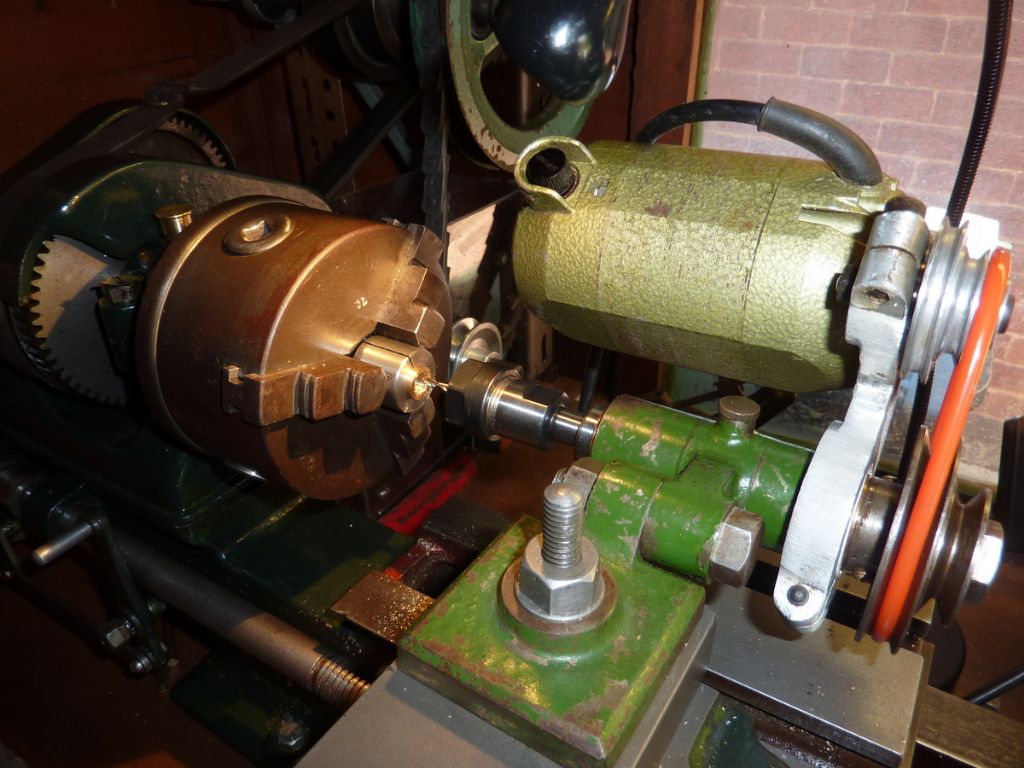

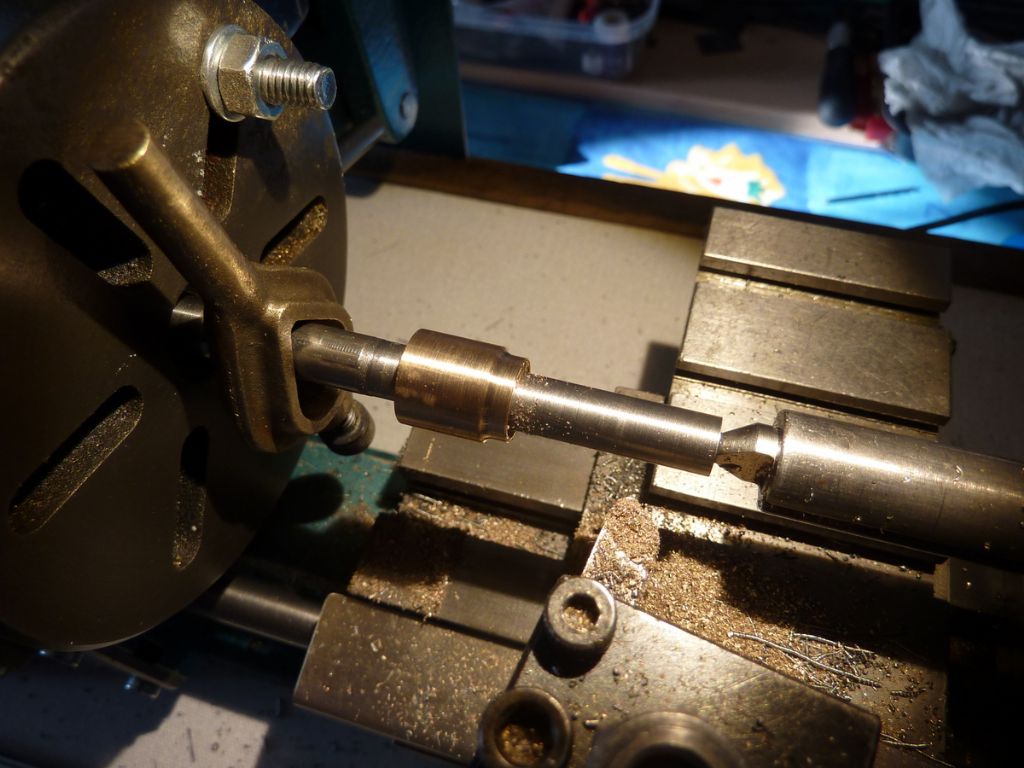

Here is dry run number 3 with tap number 1 in July and fitted to in the 'spare' saddle and cross slide that I bought last November.

As readers of the other thread may recall the tap had issues because the thread cutting tool (a recycled cheapo chinese HSS milling cutter) chipped during use and the thread grooves ended up too wide for a reason I did not figure out at the time. The good news was that the result was a working cross slide, even though the nut will only accept a very worn feed screw.

After leaving the job alone for a while I came back to it and decided to replace both the cutting tool and the raw material for the tap. A new tool was made from 6mm round HSS bought from RDG Tools. This took a couple of attempts to get right and grinding a 1mm wide threading tool from 6mm stock was pretty time consuming. The silver steel for tap 1 was from a well regarded UK supplier but I found it intermittently 'gritty' both on this and another job so I bought a new piece from a different supplier – Coventry Grinders.

Tap number 2 (again) wound up with the grooves too wide, much more severely than tap 1. This time I spotted what was going wrong. The job produces a lot of vibration and I was paranoid that the tailstock centre was becoming less firmly engaged with the job so I kept tweaking the handwheel. What was actually happening was that the tailstock tweaking was pushing the job a thou or so further into the chuck and messing up the registration of the threading tool, causing the wider groove. Armed with this experience I made tap number 3 keeping my hands off the tailstock wheel and that one worked out OK (finally!). Using tap 3 to recut nut number 3 I was finally able to get a test piece of unworn male thread to fit properly… natually the worn feed screw then had backlash.

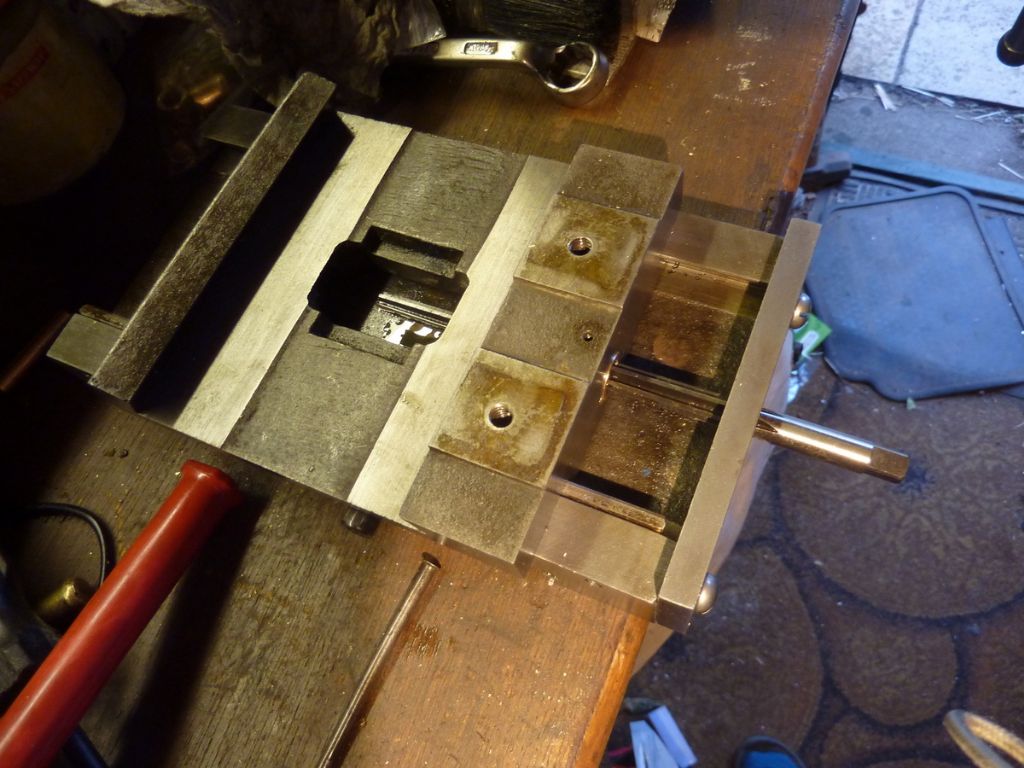

The three taps – tap 1 at the top.

Today I've finished dry run number 4. This time I ground the thread cutting tool a few thou undersize to leave more metal for the tap to remove so that any alignment errors will be dealt with by the tap.

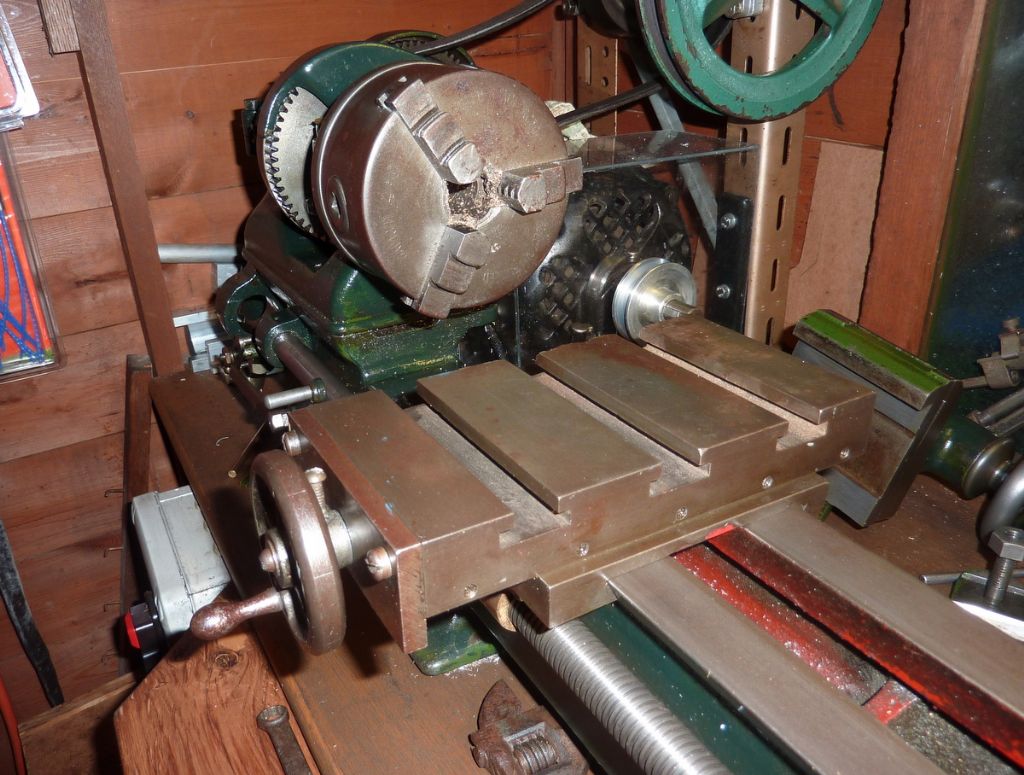

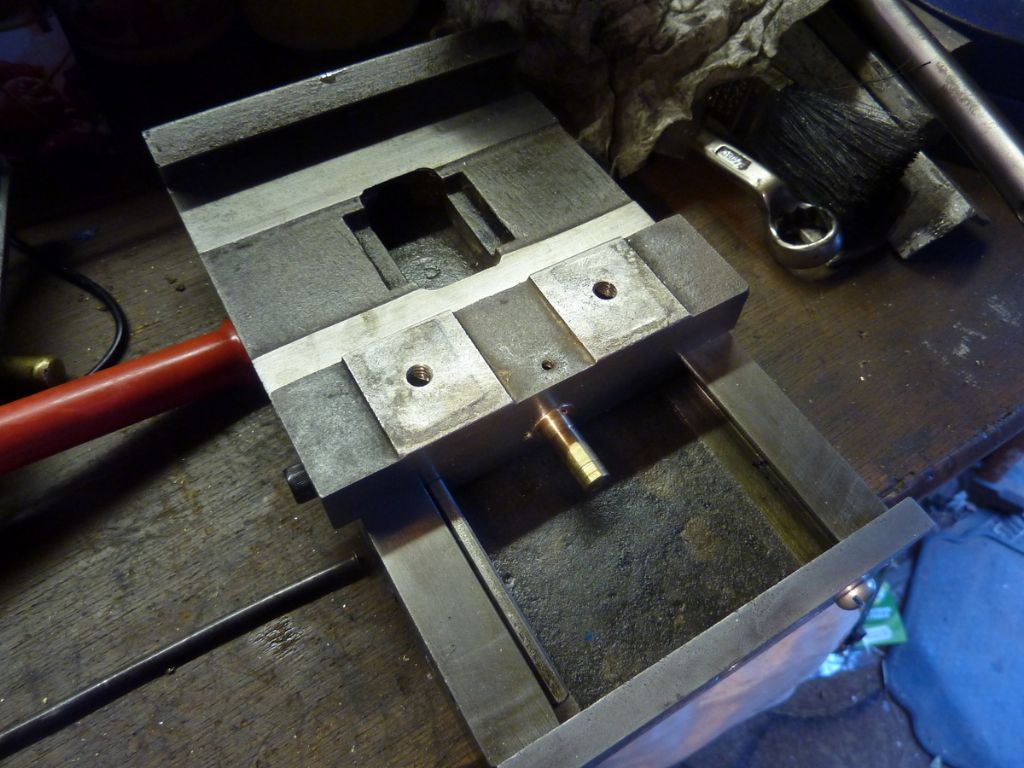

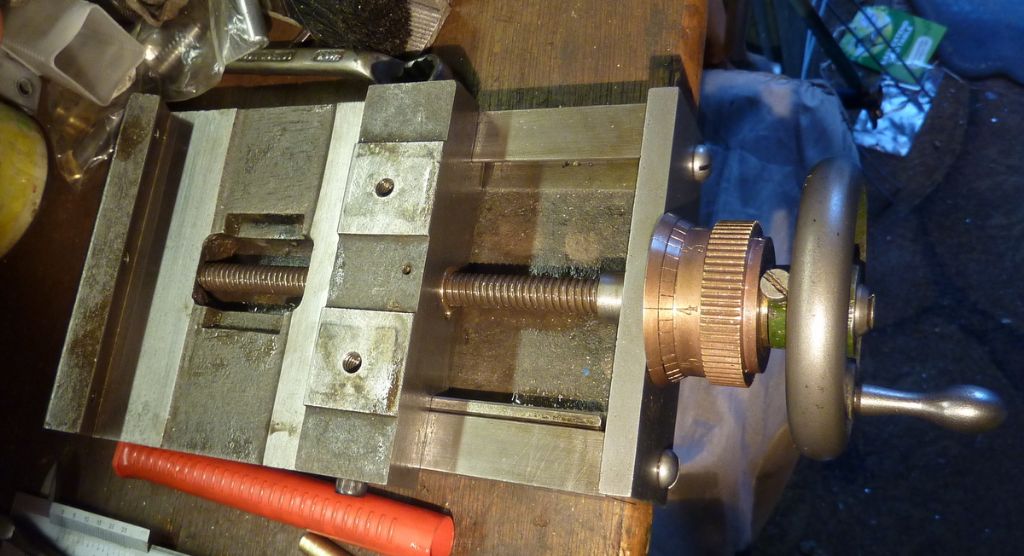

My next step was to get some 'insurance' in case the job on the 'proper' cross slide goes wrong. After a lot of fiddling about and swapping bits around, I managed to get the spare saddle and cross slde to work on my lathe. The fit is usable rather than perfect – it seems that repeatability wasn't a strong point in the Faircut factory.

While I had everything apart I noticed that the two saddles were more different than I thought. Both have aspects that are not ideal so I wonder which was earlier and which was the 'improved' design.

The lathe is now reunited with its proper saddle and cross slide ready to make what I hope will be the proper cross slide nut. This will be made from leaded gunmetal rather than the brass used for the dry runs… but that's a job for another day.

Brian Morehen.