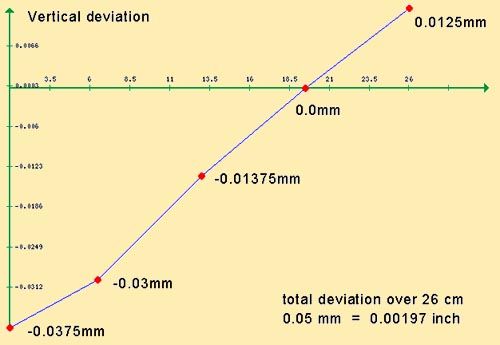

Currently, I can force some movement of the main spindle at the chuck end by virtue of inserting my fist underneath and exerting pressure. I am reading a total deviation of about 0.035mm ( = 0.00138 inch ).

Ignatz,

The play in the bearing is unfortunate, but recoverable. Is there significant side to side play, which is more of an issue?

Difficult to predict what will be worn and where, so I don't think you will 'push' the spindle down at the nose as you imply, even if you do, that will be less significant than any side to side play

The effect of squeezing the bush down will be to close that area of wear slightly, hopefully reducing play. In any case up and down play in the spindle of +- half a thou would probably not account for the amount of taper you have measured (side to side play might).

Spindle play generally manifests as poor finish rather than a tapered cut, but the forces at the tailstock end of the piece when cutting, could in theory deflect the spindle in the bearing sufficient to result in a shallower cut at the tailstock end ( and so can deflection of the work piece)

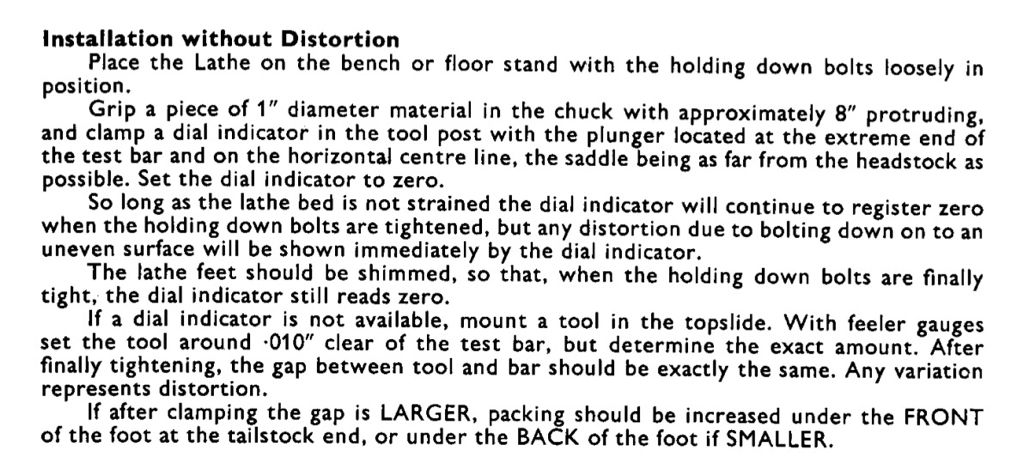

Proceed as you wish, but if it were my machine, I would do the simple checks first, headstock alignment and twist. It is easier and safer to deal with these before hacking the bearing!

If you still have a significant taper on a test piece after confirming the alignment is OK and there is no twist (and you have mounted the work deep in the chuck to avoid the effects of the jaw belling) then it is time to look at the bearing.

Check front and back bearings/spindle contact for play both lateral and vertical, The front one will have suffered the most impact, but they need to be considered together. The amount of wear is not that great an you have the right approach – proceed delicately! Lap off half a thou at a time from the shim and recheck the spindle movement. Personally, anything less than 1/2 a thou play static would do me. If you go tighter, make sure to run the lathe up at high speed for half an hour (with oil) and check to see the bearings are not warming up unduly.

If you are going to the trouble of adjusting the bearing shims, you may want to consider taking the spindle out to remove any gunk/swarf etc from the bearings giving the lot a good clean. It is unlikely you will damage the headstock with the level of adjustment proposed, just make sure you remember to reinsert the shim before cranking down on the bearing bolt and check spindle rotation by hand as you tighten up STOP as soon as the spindle starts to feel the least bit tighter

You will never reduce the errors to zero so don't sweat the small stuff!

Ignatz.