Hi, Philip,

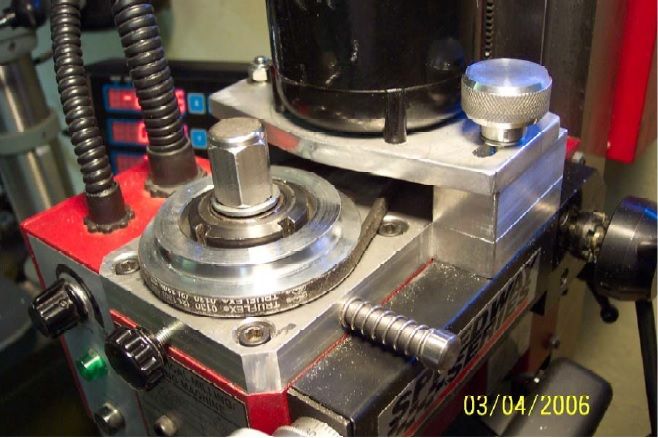

I converted my mill (Seig X2 type) to belt drive long ago, without using a kit. I recently upgraded it to use a 3-phase motor, with the same belt drive. I posted some pics of this conversion on this forum on which you can see the conversion, but it is not very clear.

It is a simple mod to do – basically remove the cast iron plate on the top of the mill – the drive gears are under this. I replaced this iron plate with a 6mm aluminium plate which carried the motor, and bought and modified two toothed pulleys to fit the head input shaft and the motor, and connected them with a short toothed belt. The motor mounting plate is remounted in place of the old cast iron plate using 6 aluminium spacers – this has been worked hard now for at least 15 years, and I haven't broken a drive belt yet. I made a new motor mounting plate because I needed to move the motor back a few millimetres to make the belt a good fit – there is room to do that. This mod also keeps the mechanical two-speed system on these lathes – some belts mods eliminate it. (and a 3-phase motor with VfD eliminates the need for it completely)

I'm sorry I am travelling away from home over Christmas/New Year, but if you are interested, I could run up a few sketches to make it clearer when I get back – the belt/pulleys were only a few Euros when I did it (20 Euro?), and a days work to make the ally plate and fit it.

Its a big improvement – most of the noise stops (caused by the gears), and the 'feel' of the mill is much better – more stable – I don't know how else I can describe it. Fitting the 3-phase motor (at a later date) was another good move – it is only a 1/2 HP motor, but is much smoother and more powerful than the old DC thing, and it removes the chance of unreliable controller board failure and 'death of motor' these mills suffer from. (spares are v. expensive!)

BTW – this mod is reversible – if you don't like it, or something go wrong, you still have the original parts to revert to standard.

Edited By An Other on 24/12/2021 11:57:36

Clive Farrar.