Hi Tom

I bought a Clarke / Machine-mart variant couple years back , works Ok,…Though i think the Warco one is better priced and has a bit bigger motor fitted to it,

One the worst aspects of the clarke is the belt tension adjustment is not as good as it could be ( have not got around to doing anything about it as yet, other than cutting a couple of hard wood wedges to apply pressure between the gear box & the motor casing ), ..the tension bolt is not really in the right / ideal place…. will do some thing about some when , needs a better motor carrier plate / frame making .

I did think the stand was a bit flimsy , so cut four bit of angle iron so as to make a frame to stand the stand in , then drilled two 6.5mm holes through the end pieces of angle and the tin ends of the stand, and secuerd it with 6 mm bolt each end, which firmed it all up, and put some better wheels on

As for the tin table supplied, i didnt even bother ! ..that was very first mod, made a small sub plate out a bit 6 x 4 x 3/8 inches ms then used 1/4 inch thick ally plate 11 x 12 inches bolted to the sub plate using 8 mm c/s allan screws

The one thing i would change , would be to fit braked casters to the corners of the angle iron frame , as its still a bit of a pig to move easily using just two wheels at the heavy end. though a trailer type jockey wheel might be an option !

I think the motors used on these m/c are just the standard type capacitor run type ,ie the capacitor is permanently in circuit , not the type that has c/f switch fitted internally so not cap start / cap run.

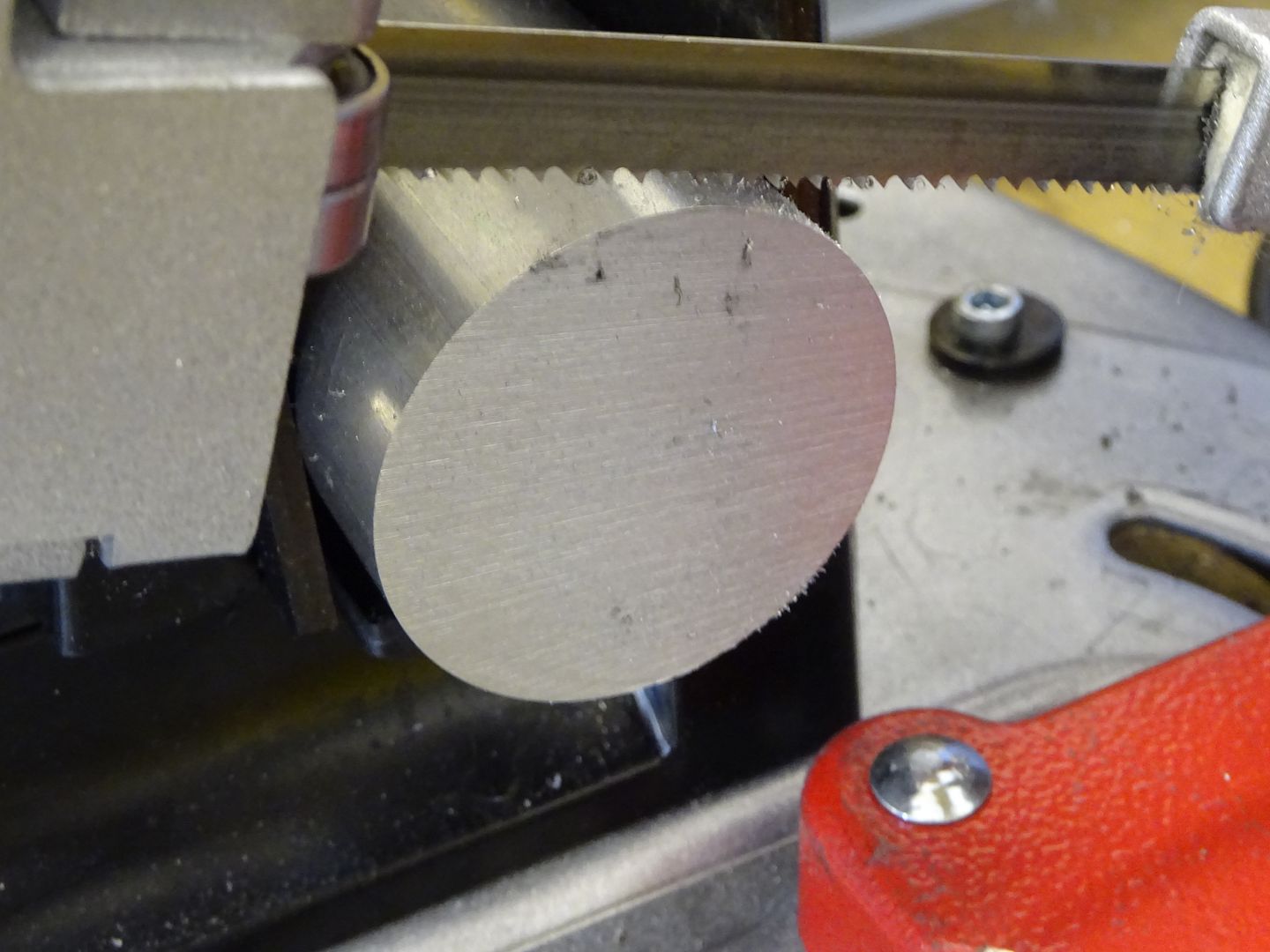

Beats the hell out hack sawing…………………b

Saw a bit on you tube where the chap was hard soldering blades, might be worth a look if any ones interested ……..

Edited By bodge on 03/01/2017 16:24:22

Steviegtr.

Steviegtr.

Maybe this is Jason's old Rexon.

Maybe this is Jason's old Rexon.