It had been suggested that such a device would be a good idea for my lathe as the weedy 150w motor combined with the low speed used when cutting threads would put too much of a strain on it.

So after some research (here and Youtube) I started gathering bits. First an M6 Rawl bolt was obtained, this was more to get an idea of how the thing would work, but it turned out that the taper end of the bolt fitted perfectly into the spindle of the lathe. The bore being 10.5mm or so. Clearly the rest of the bolt was useless for this purpose.

I took a length of 15mm brass and turned down a section to 10.5mm then drilled it 6mm through. The allowed me to insert the bolt and mark out where the three slots would be. I wanted to retain the raised ridges on the taper so that the bolt would not rotate once engaged.

I used a V profile tool in the lathe and used it to scribe lines from the ridges along the length of the 10.5mm section, then hand rotated the chuck to mark out the ends of the slots.

I drilled 2mm holes where the slots would end, bored the inside out to 8mm up to these holes and then cut a 13 degree taper inside to match the taper on the bolt.

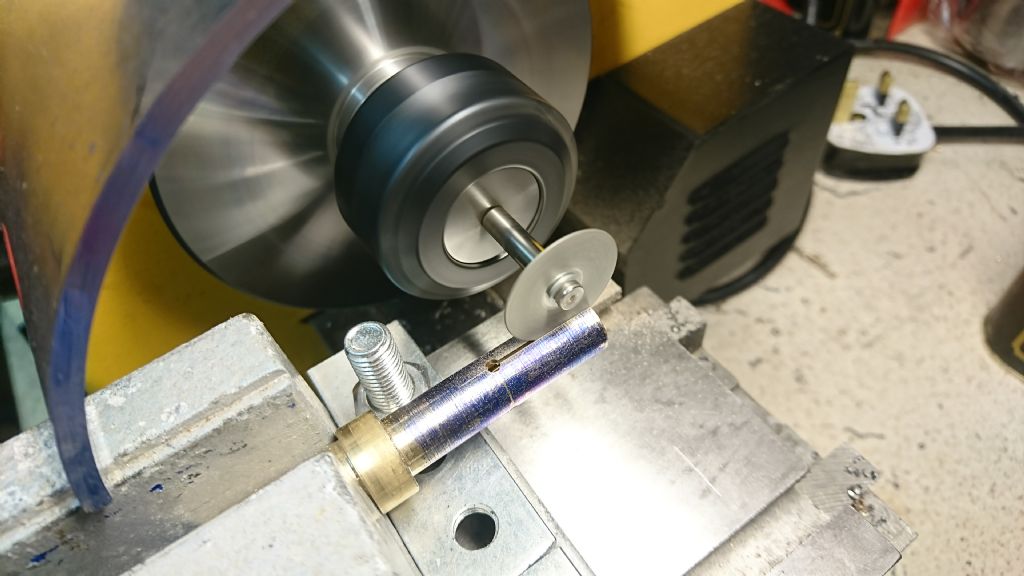

Using a machine vice clamped to the cross slide I cut the slots with a diamond wheel in the chuck

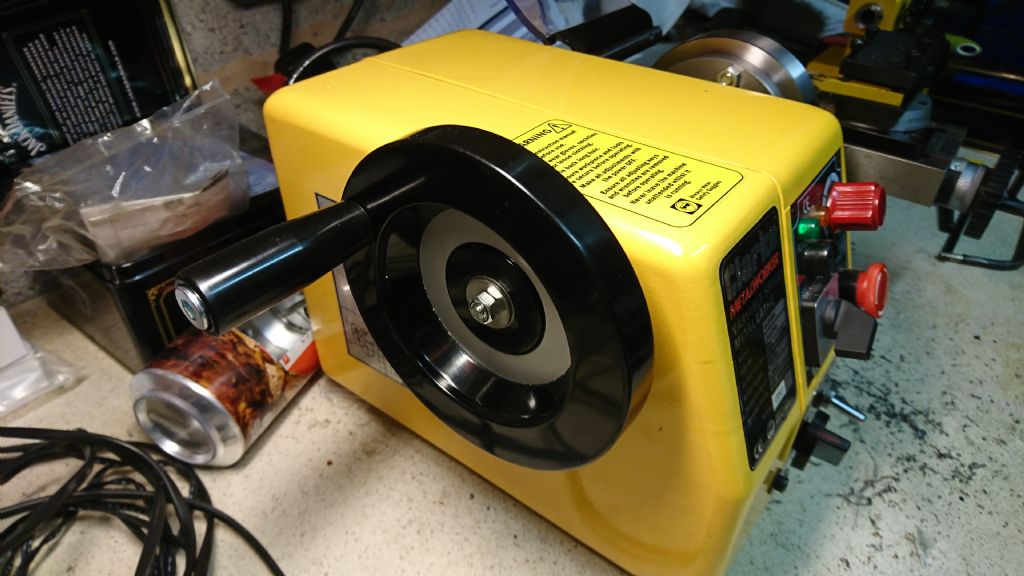

I had also turned down the rear of the mandrel to 12mm to match the handwheel I bought from RGD – a bargain at just over a tenner I thought.

Now, I do not have access to a milling machine, a slide is on my birthday list, but that is not until June. So I drilled and tapped three m4 holes and loctited short lengths of m4 stud into them. Once filed down to 2mm high they made a good key for the handwheel

An m6 penny washer served to hold the handwheel in place once the nut was tightened up.

Here's the parts – note I've Gun Blued the mandrel, as I had a bottle handly.

and here's it in place on the lathe. I can remove the handle on the wheel quite easily if I want to leave the wheel in place for a bit too

The mandrel is a bit dwarfed by the handwheel, maybe I bought a size too big, but I thought bigger is better

Edited By Ian Mellors on 26/03/2021 09:11:02

Edited By Ian Mellors on 26/03/2021 09:16:13

Ian Mellors.