Posted by Ajohnw on 13/10/2016 11:04:49:

Posted by Michael Gilligan on 13/10/2016 00:00:17:

Posted by Roderick Jenkins on 12/10/2016 23:44:17:

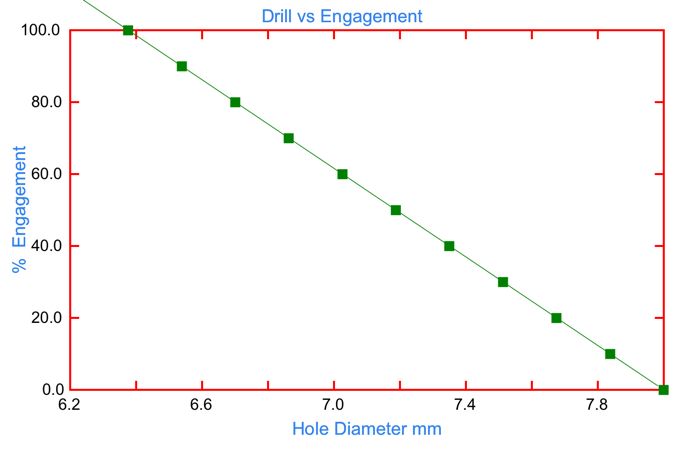

The link suggests that engagement values of 60-70% are applicable to most situations. Putting a value of 65% for 8×1.25 gives a drill of 6.95mm, rather bigger than the 6.8mm drill they have supplied to Mark which gives 74% engagement.

.

And putting 70% for engagement gives

If nothing else; this clearly demonstrates how sensitive 'engagement' is to hole size

… I say hole, rather than drill, for obvious reasons

[we've been exercised enough recently, regarding run-out, etc.]

MichaelG.

Well spotted Michael.

On the other aspect how sharp and true is the tip of the drill. I'm hoping my Medding drill that I put together last night is really square and true to the table. It will help a lot with reaming in particular. Just need to find a 240v motor now.

I'm surprised that some one hasn't worked out what the actual core size of what a typical 8.1mm dia tap is. Still iffy though.

Yes Mark – I have made use of thread go no go guages. Not at home though. The ring types as well.  Using hand ground lathe tools too.

Using hand ground lathe tools too.

John

–

Now John, why did you suggest that with over 200 replies already to tap a humble hole!!  but here it is:

but here it is:

Minor dia. or core dia of nut = basic OD -1.082P

Also that 8.1 dia tap has a reason! Above the max OD the nut form is radiused for clearance on ISO Metric and Unified thread forms by 0.072P which would mean on our M8 x 1.25 tap should be around 8.09 dia. plus tolerance. This of course has nothing to do with the fit of the nut on the screw unless the screw has a sharp V on the crest and is also over the basic dia of the thread. The fit is always controlled by the effective diameters.

And of course this has nothing to do with anything generally other than Toolroom talk but sometimes for some people "it's just nice to know" ! Now back to the shed in OZ.

Edited By D Hanna on 13/10/2016 12:41:54

Mark C.