After dunking the nuts in white spirit to loosen the gunge they cleaned up reasonably well, seems the lack of engagement has protected the root of the threads in the nuts. Think it is necessary to point out here to non Raglan owners or past owners, that the half nuts are an interesting experiment in Mazak casting. A replacement for all the parts is being considered, either fabricated or also potentially a 'lost wax casting' in bronze. Seems like a good area to use a 3D printer!!

The engagement cam has broken out so that is being replicated in bronze pinned to a steel shaft, the half nut holder (a square 'box' with T slots which locates the half nuts, could be made in bronze and the nuts again could be fabricated by bronze brazed to a steel plate base.

What surprised me was the wear in the 10 DP worm gear in the power engagement box, the bronze gear had shortened by about 0.15" . Here are some photos of the upgrade work:-

Welded repair to a 'new' power traverse bracket – this bracket had not seen much use but the detent plunger housing was snapped off – Farmer Hedley worked his magic with the electric glue!

The 'new' bracket with the power shaft keywayed gear and new 10 DP worm wheel assembled – original worm wheel at right

![img_3475[1].jpg img_3475[1].jpg](data:image/svg+xml;base64,PHN2ZyB3aWR0aD0iMSIgaGVpZ2h0PSIxIiB4bWxucz0iaHR0cDovL3d3dy53My5vcmcvMjAwMC9zdmciPjwvc3ZnPg==)

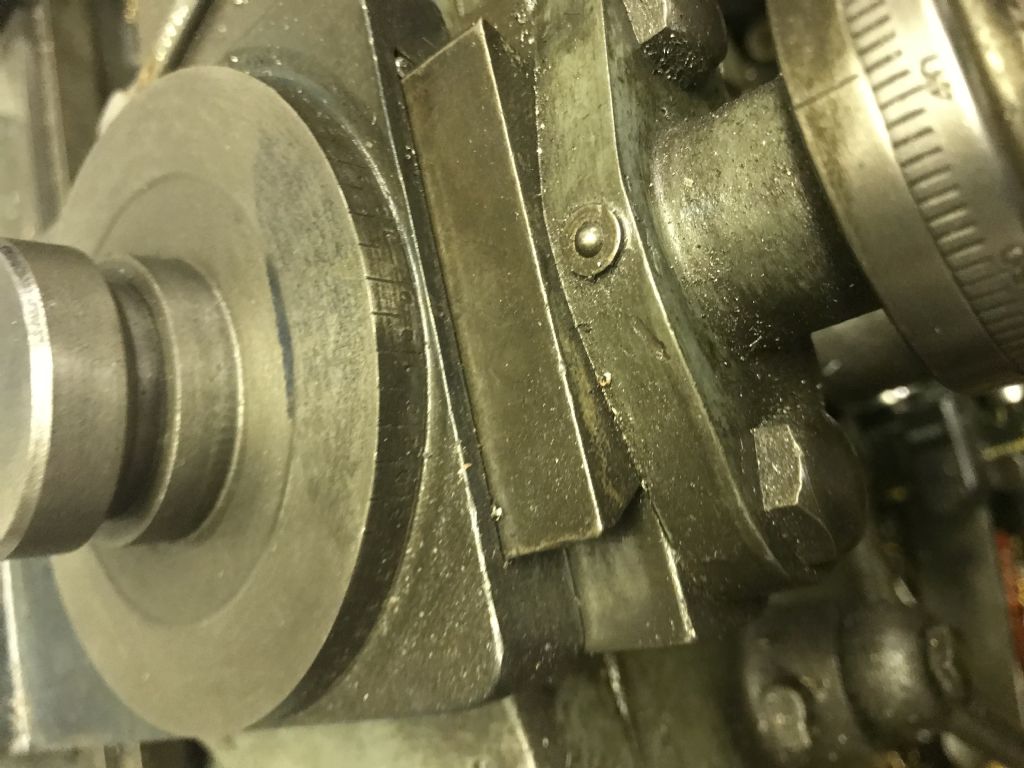

Original power shaft traverse bracket showing extent of wear on the thrust face of the bracket along with the original 10 DP worm wheel – this will go back into the 'stores' for renovation at a later date – I never throw anything away!

Half nut assembly after cleaning – enough thread left for the time being but new half nuts need to be made.

Saddle carriage rack pinion – upper unit repaired with a new bronze gear – pinned to the original shaft. Lower one showing teeth damage. I have a new rack to fit to the machine.

My 'long' X slide modification – compare the thickness of the deck with the photo below of a commercially available 'long' cross slide. This X slide is replaced by a 'short' version when utilising the taper turning attachment. The TTA is a story in itself as it was purchased from Myfords many years ago as a part of a collection of unmachined castings for Raglan LJ's they had left over from their take over of Raglan Engineering (1954) Ltd,.

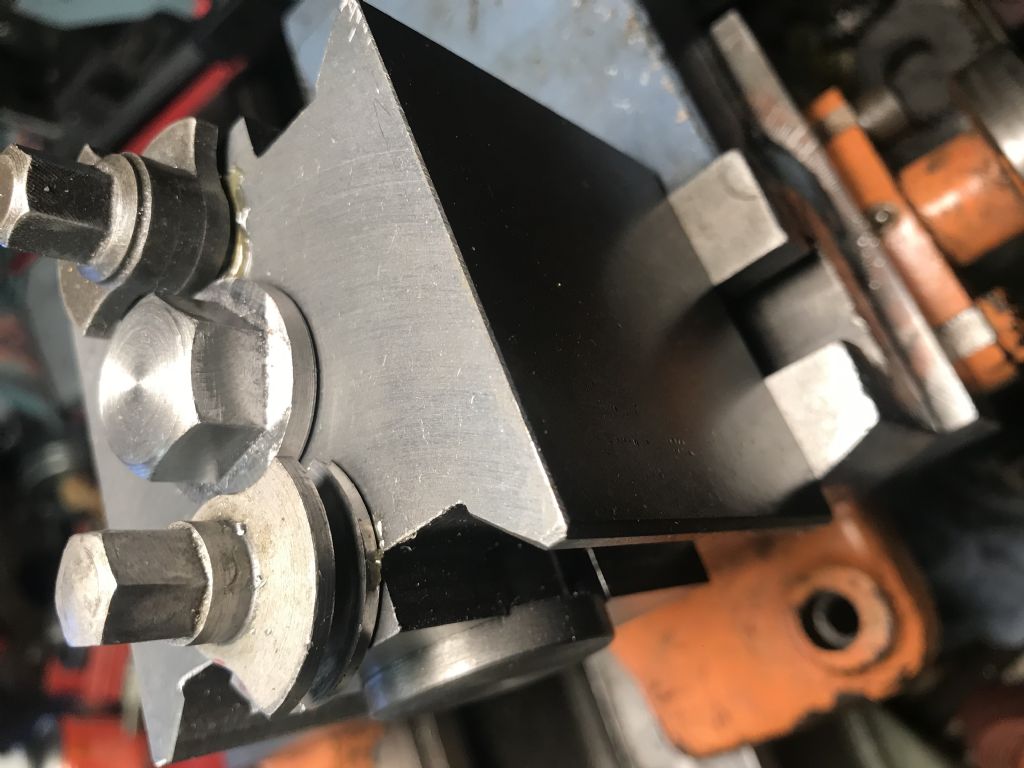

Finally my home made Dickson 'clone' toolpost. Made to suit the tool height of the Little John as it falls between the 'normal' offerings from Bison and others. I made it 2 station as on my Bison model I never found a use for the third station.

View of the second tool station.

Oily Rag.

![img_3475[1].jpg img_3475[1].jpg](/wp-content/uploads/sites/4/images/member_albums/58814/880728.jpg)

. They were either a direct copy or (more likely) bought in directly from the US.

. They were either a direct copy or (more likely) bought in directly from the US.